Sheet-metal clutch, comprising at least two clutch disks

A clutch plate and clutch technology, applied in the field of clutches, can solve problems such as low compensation function, hindering economical manufacturing or processing, and failure to realize compensation function, etc., to achieve the effects of saving structural space, improving pulling performance, and saving axial structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The drawings are only schematic in nature and are used only for understanding the invention. Identical or similar elements are provided with the same reference symbols and will not be described again. Elements of one embodiment can also be used in other embodiments, thus, the elements can be interchanged with each other.

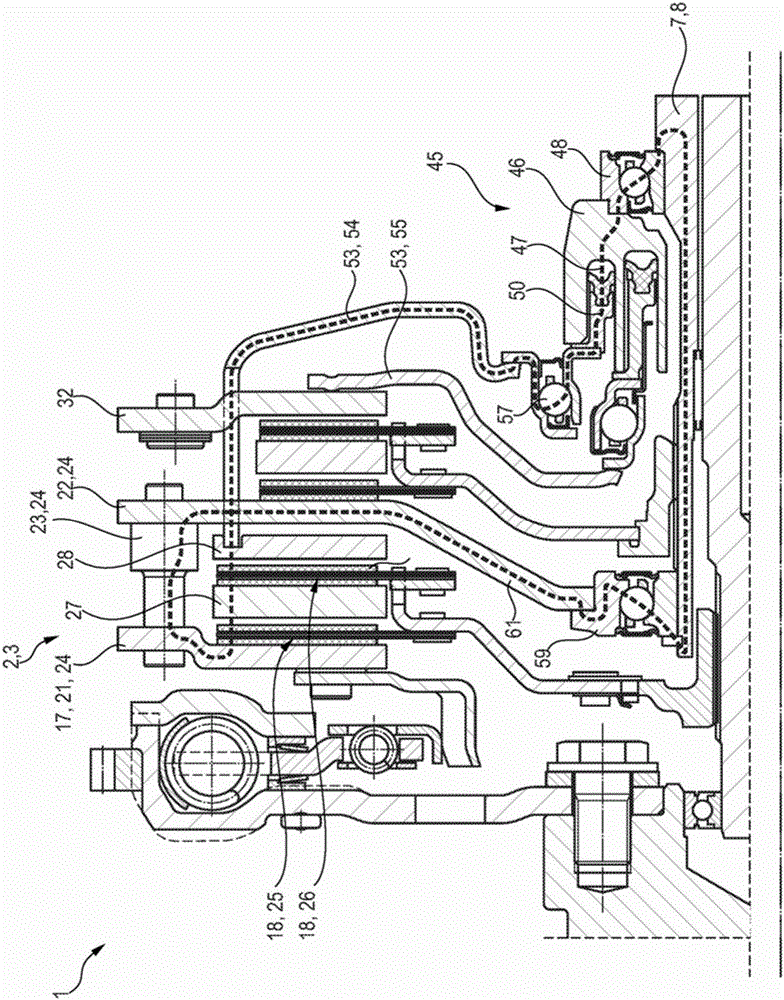

[0056] figure 1 A view along the longitudinal or rotational axis X of a clutch 1 is shown, which is designed as a double clutch with two normally open or automatically disengaged partial clutches 2 , namely a first partial clutch 3 and a second partial clutch 3 . sub clutch 4. By closing or actuating the first partial clutch 3 , the crankshaft 5 of the internal combustion engine (not shown) can be coupled to the first transmission input shaft or the inner transmission input shaft 6 for power transmission or power transmission, and by closing or actuating The second partial clutch 4 can couple the crankshaft 5 to a second or outer transmission input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com