Miniaturization high-power brushless direct-current motor controller and layout structure thereof

A brush DC motor and controller technology, applied in current controller, torque ripple control, etc., can solve the problems that do not meet the requirements of miniaturization and light weight of the aviation system, high maintenance cost, heavy weight, etc., and achieve the best application The effect of promoting prospects, reducing volume, reducing volume and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

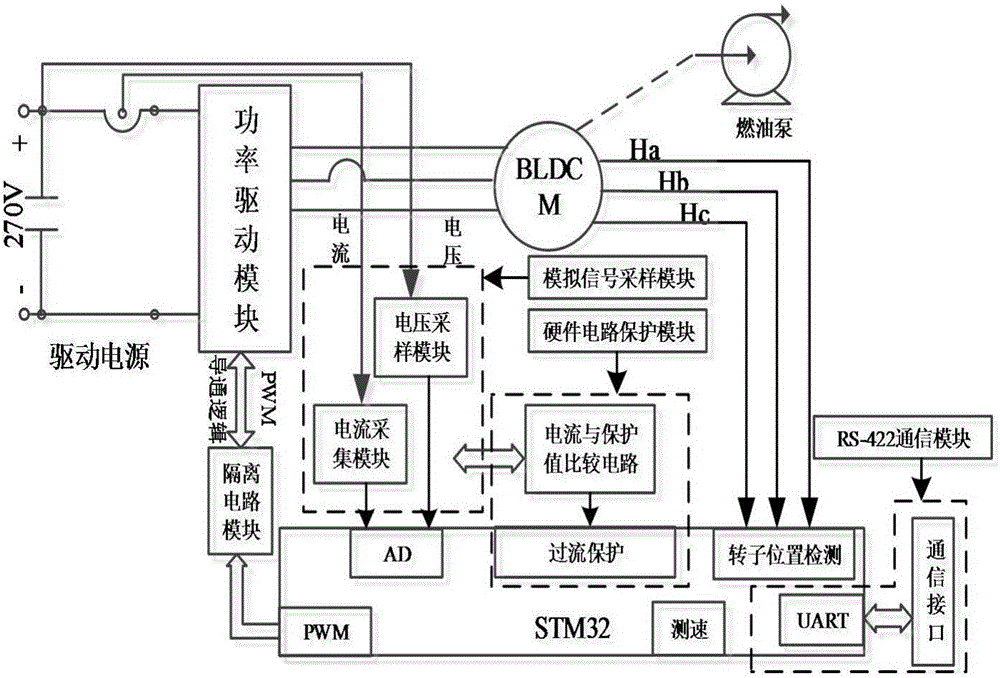

[0030] Such as figure 1 As shown, the present invention includes an STM32 core controller module, an analog signal sampling module, an isolation circuit module, a power drive module, a hardware protection circuit module and an RS-422 communication interface module. The power drive module adopts the IGBT three-phase full-bridge power inverter module of Semikron (Semikron), the model is SK200GD066T. The structural layout of the inverter reduces the occupied volume a lot. Since the entire back is a heat sink (copper material), the heat dissipation effect is good, and it is very suitable for the miniaturization of brushless motor drivers. The maximum collector-emitter voltage VCES of a single IGBT inside it is 600V , the maximum collector current IC = 200A, in line with the drive power requirements of this high-power motor. The hardware circuit protection module ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com