Lithium ion battery porous germanium anode material and preparation method and application thereof

A polycrystalline germanium and porous structure technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low Coulombic efficiency, failure to meet practical requirements, and short battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

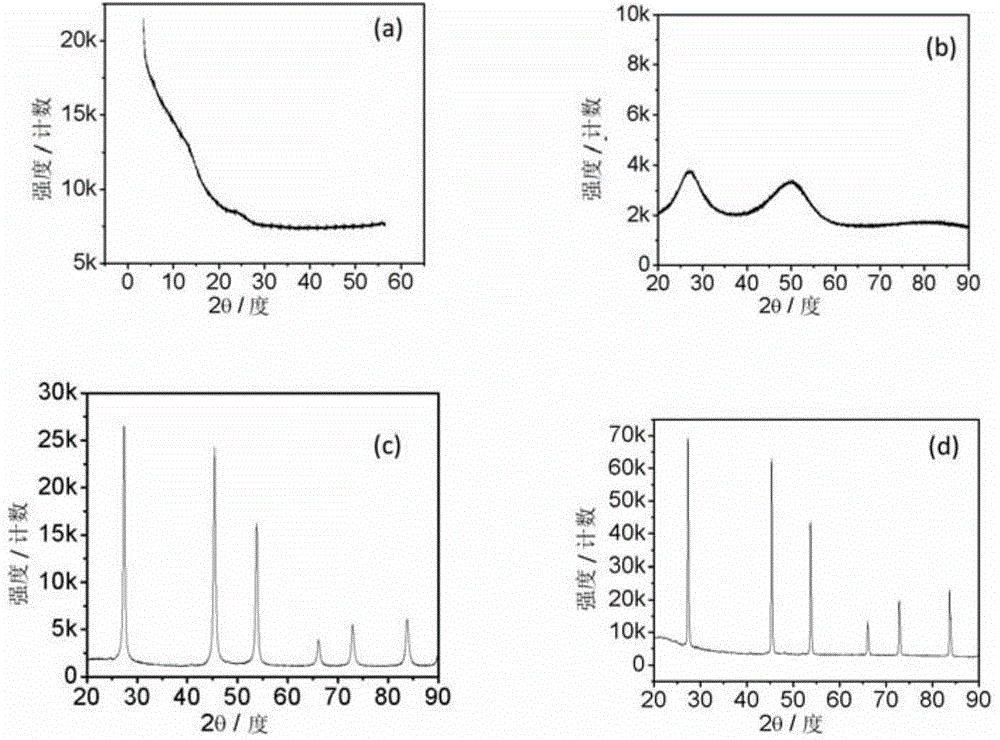

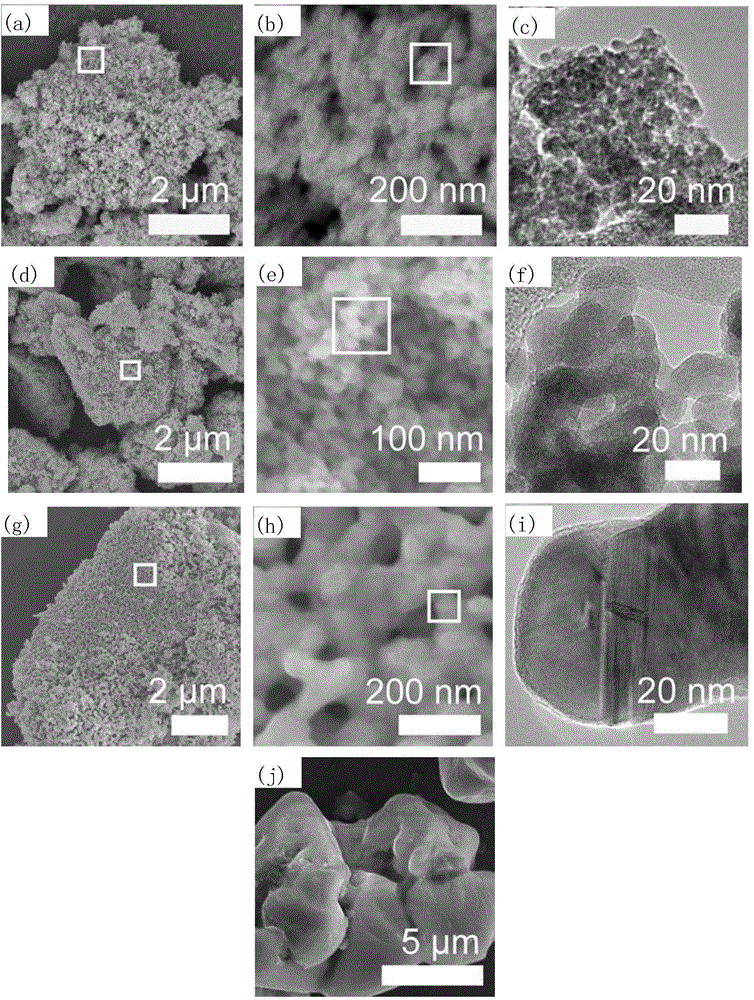

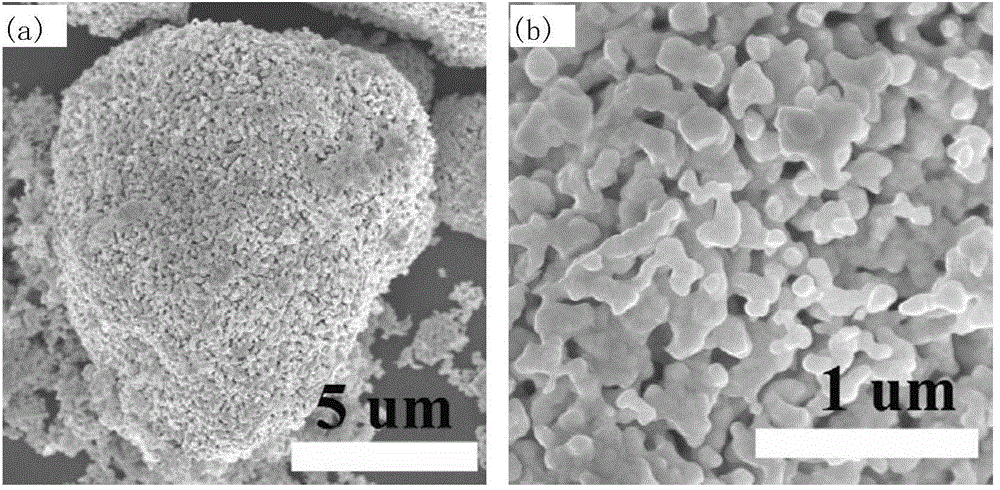

[0142] The present invention provides a kind of preparation method of described germanium material, described method comprises the steps:

[0143] 1) providing an amorphous germanium oxide raw material, said germanium oxide raw material comprising agglomerates formed by primary germanium oxide compound particles with a particle size of 5-30 μm;

[0144] 2) Under a reducing atmosphere, heat-treat the germanium oxide raw material at 350-650° C. to form the germanium material.

[0145] In another preferred example, the germanium oxide raw material is in an amorphous state.

[0146] In another preferred example, the particle size of the agglomerates formed by the primary germanium oxy compound particles is 6-25 μm, preferably 7-20 μm, more preferably 8-15 μm.

[0147] In another preferred embodiment, the agglomerates are granular and have a porous structure, and the porous structure is formed by agglomerating primary germanium oxide compound particles.

[0148] In another prefer...

Embodiment 1

[0218] Preparation of germanium material 1

[0219] Put 1.35 grams of germanium oxide raw material of about 8 microns in a tube furnace, the atmosphere is hydrogen, the flow rate is 50-60 sccm, the pressure is 10 psi, the heating rate is 50 degrees per minute, the holding temperature is 500 degrees, and the holding time is 30 minutes , naturally cooled after the heat preservation, and obtained the germanium material 1.

Embodiment 2

[0221] Preparation of germanium material 2

[0222] Place 4 grams of 12-micron germanium oxide raw material in a tube furnace, the atmosphere is hydrogen, the flow rate is 50-70 sccm, the pressure is 15 psi, the heating rate is 55 degrees per minute, the holding temperature is 500 degrees, and the holding time is 50 minutes. After the heat preservation is completed, it is naturally cooled to obtain the germanium material 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com