Automobile tire vibration excitation device and method for automobile in amplitude adjustable running state

A vibration excitation device, a technology for automobile tires, applied in measurement devices, vibration testing, vehicle testing, etc., can solve problems such as unsatisfactory equipment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

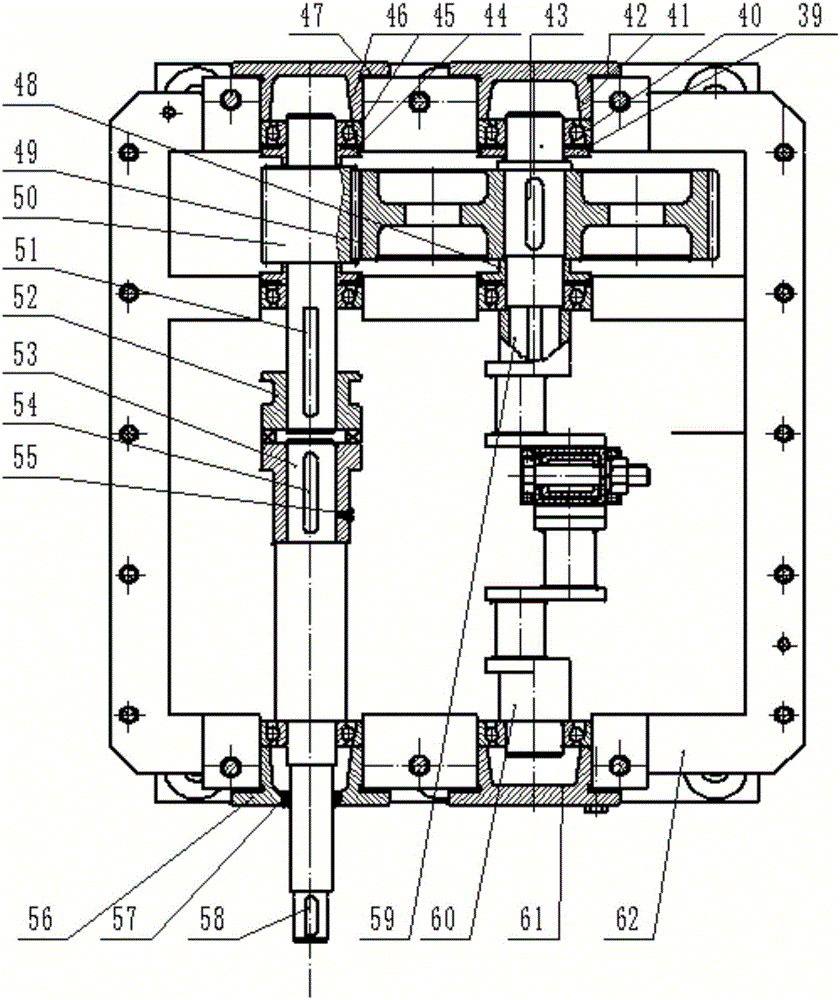

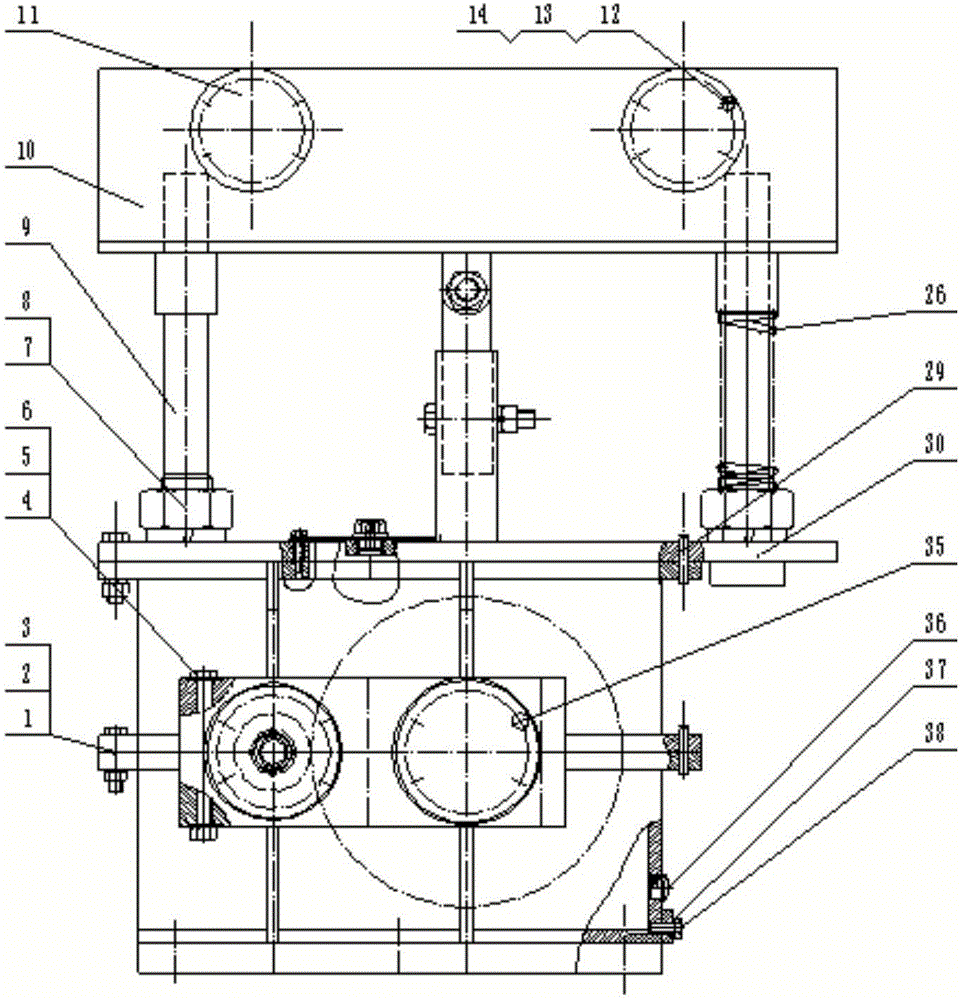

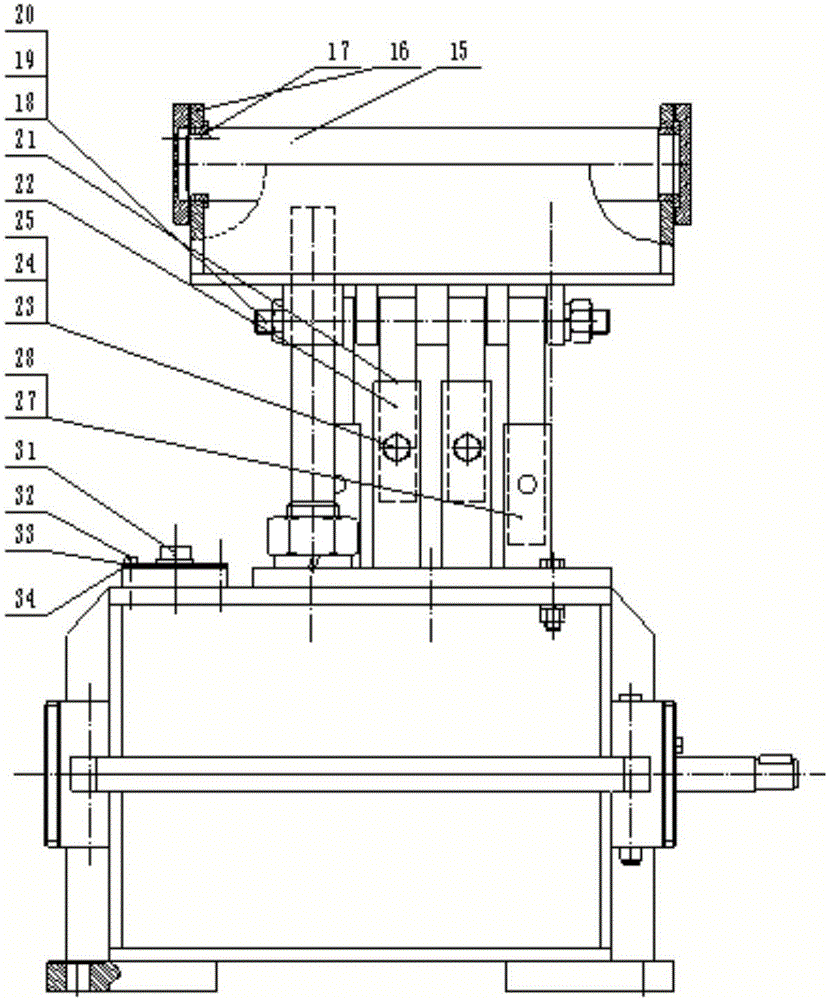

[0032] An automobile tire vibration excitation device with adjustable amplitude in a driving state, the device includes a vibration excitation device, a transmission mechanism and a tension mechanism; the vibration excitation device includes a crankshaft 60, an upper push rod 21, a lower push rod 22 and a stage , the crankshaft 60 is installed inside the lower casing, and the crankshaft 60 is a rotatable structure; one side of the crankshaft 60 is connected with the low-speed shaft 59 through a key connection, and the other side is arranged on the lower casing through a bearing, and the lower push rod 22 passes through the lower casing. The box body is fixed on the crankshaft 60, and the upper push rod 21 is a structure that can slide relative to the upper push rod 21 and is temporarily fixedly connected with the lower push rod 22 through a pin when needed; They are the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com