Fire cover for gas stove

A gas stove and fire cover technology, which is applied in the fields of application, burner, and combustion method, can solve the problem that the gas stove fire cover does not have a flame-stabilizing function, and achieve good flame-stabilizing effects, reduced processing difficulty, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

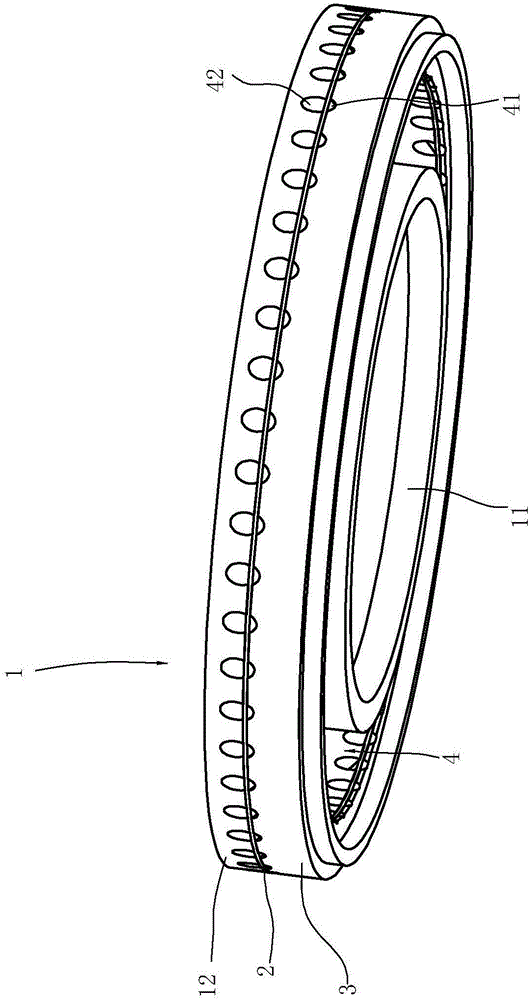

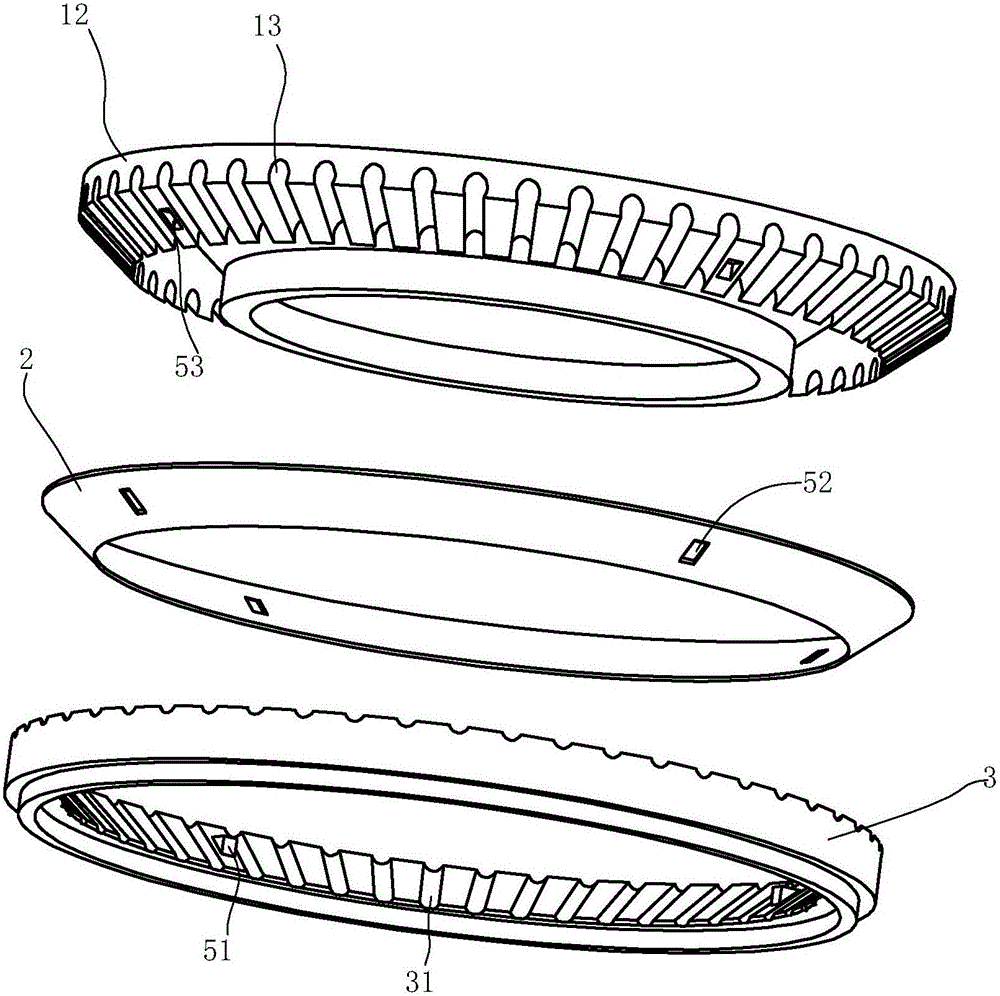

[0020] Such as Figure 1 to Figure 3 As shown, the fire cover for the gas range includes:

[0021] The upper cover body 1 has a ring structure. The inner ring and the outer ring of the upper cover body respectively have an inner ring wall 11 and an outer ring wall 12 extending downward, and the lower peripheral surface of the outer ring wall 12 is a conical surface with a high outside and a low inside. shape and has a plurality of radially penetrating upper grooves 13 along the circumference.

[0022] The lower cover body 3 is adapted to the outer ring wall 12 and is arranged below the outer ring wall 12. Its upper surface is also a conical surface with a high outside and a low inside, and a plurality of lower grooves 31 radially penetrating along the circumference. .

[0023] In this embodiment, the lower grooves 31 correspond to the upper grooves 13 one by one.

[0024] The spacer 2 is arranged between the upper cover body 1 and the lower cover body 3, and its upper surfa...

Embodiment 2

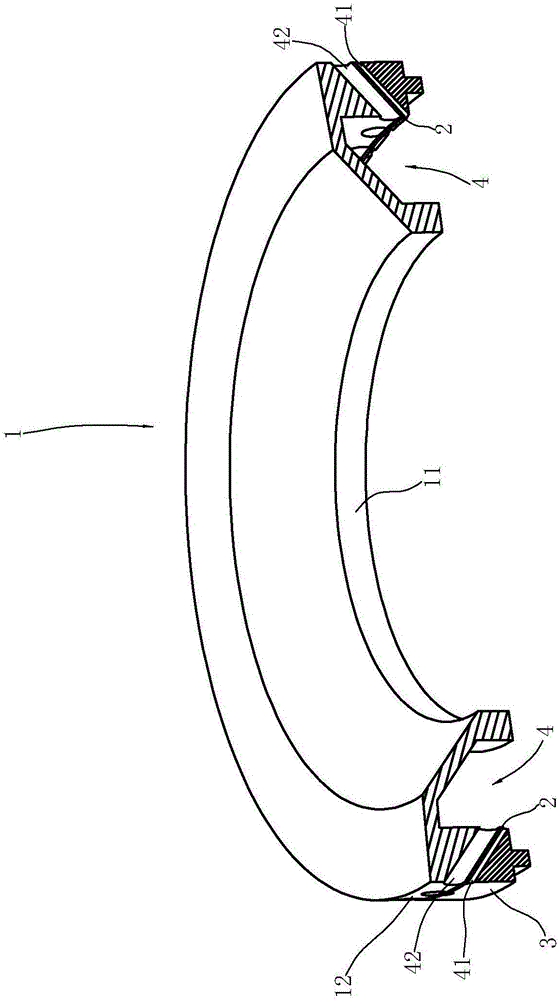

[0033] Such as Figure 4 to Figure 6 As shown, in the gas cooker fire cover in the present embodiment, the outer end side of the outer ring wall 12 is slightly protruding from the outer end side of the lower cover body 3, so that the stable flame flame of the lower fire hole is directly on the upper fire hole. root burning;

[0034] The cross-sectional area of the upper fire hole is three times the cross-sectional area of the lower fire hole;

[0035] The spacer 2 intersects with the horizontal plane at an angle of 65°; correspondingly, the tapers of the lower peripheral surface of the outer ring wall 12 and the upper surface of the lower cover 3 are both 65°.

[0036] All the other contents are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com