Backlight module and application thereof

A backlight module and chromatic light technology, applied in optics, light guides, electric light sources, etc., can solve problems such as unfavorable display thinning, high-order diffracted light crosstalk, and lower color saturation of display panels, so as to improve light extraction efficiency and save raw materials Effect of cost and optical film reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

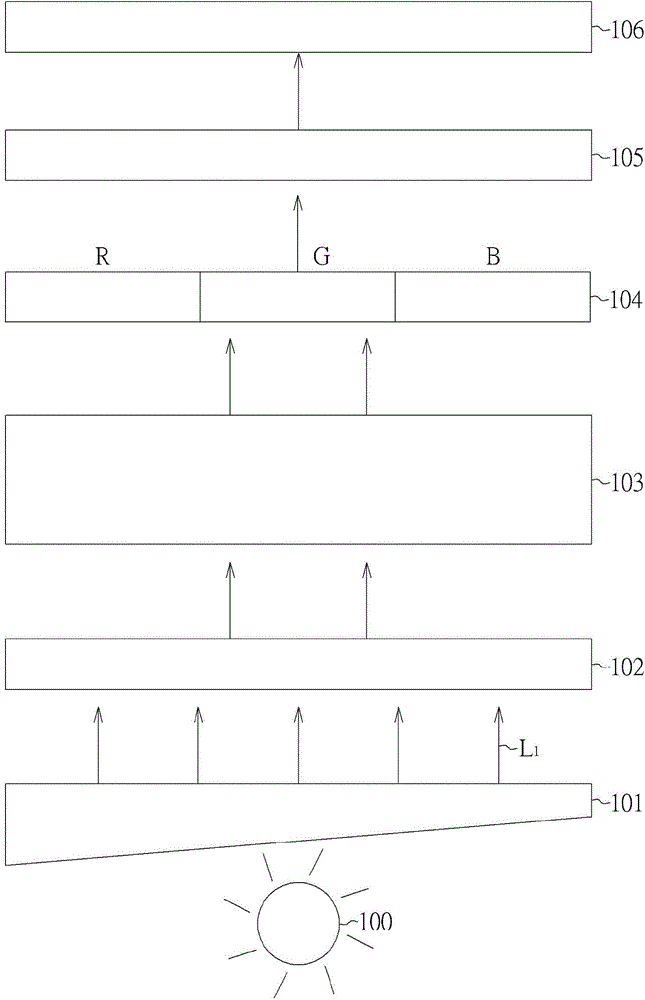

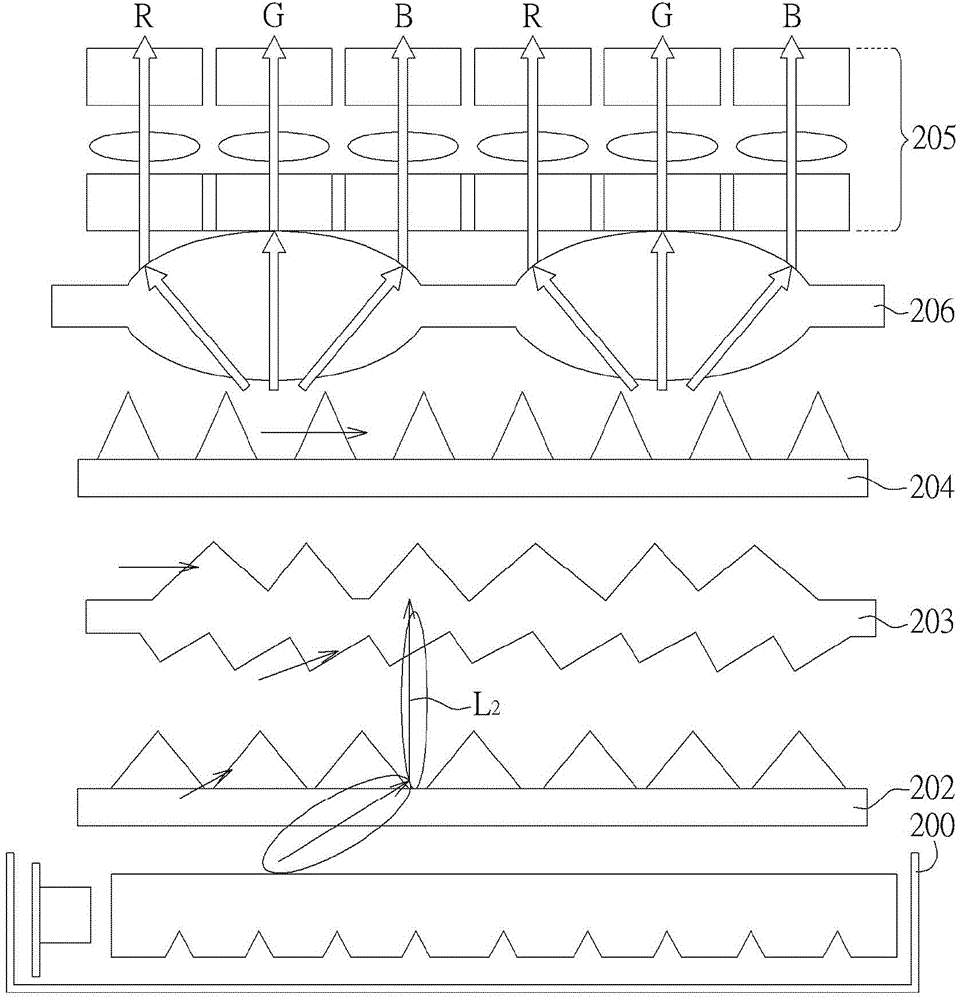

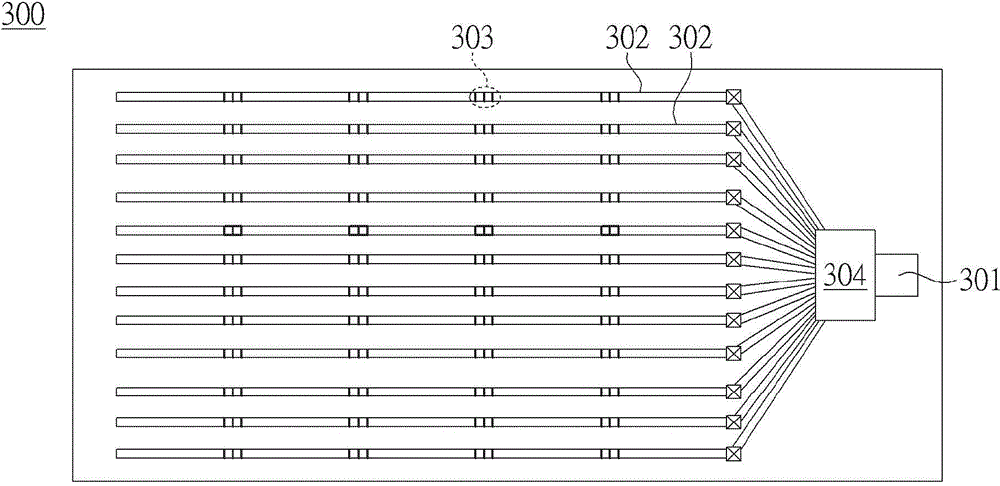

[0073] The invention provides a backlight module with a waveguide and a display device using the backlight module, which can reduce the use of optical films and save power while improving the light extraction efficiency of the display device. Further, the purpose of saving raw material cost and making the display thinner is achieved. In order to make the above-mentioned embodiments and other objectives, features and advantages of the present invention more comprehensible, several preferred embodiments are specifically cited below and described in detail with the accompanying drawings.

[0074] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The invention can still be implemented with other features, elements, methods and parameters. The proposal of the preferred embodiment is only used to illustrate the technical features of the present invention, and is not used to limit the claims of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com