Washing machine damping mechanism and washing machine

A shock absorbing mechanism and a washing machine technology, applied in the field of washing machines, can solve problems such as poor shock absorbing effect, uncompact structure, and heavy washing machine distribution, and achieve the effects of good shock absorbing and noise reduction, good shock absorbing effect and volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

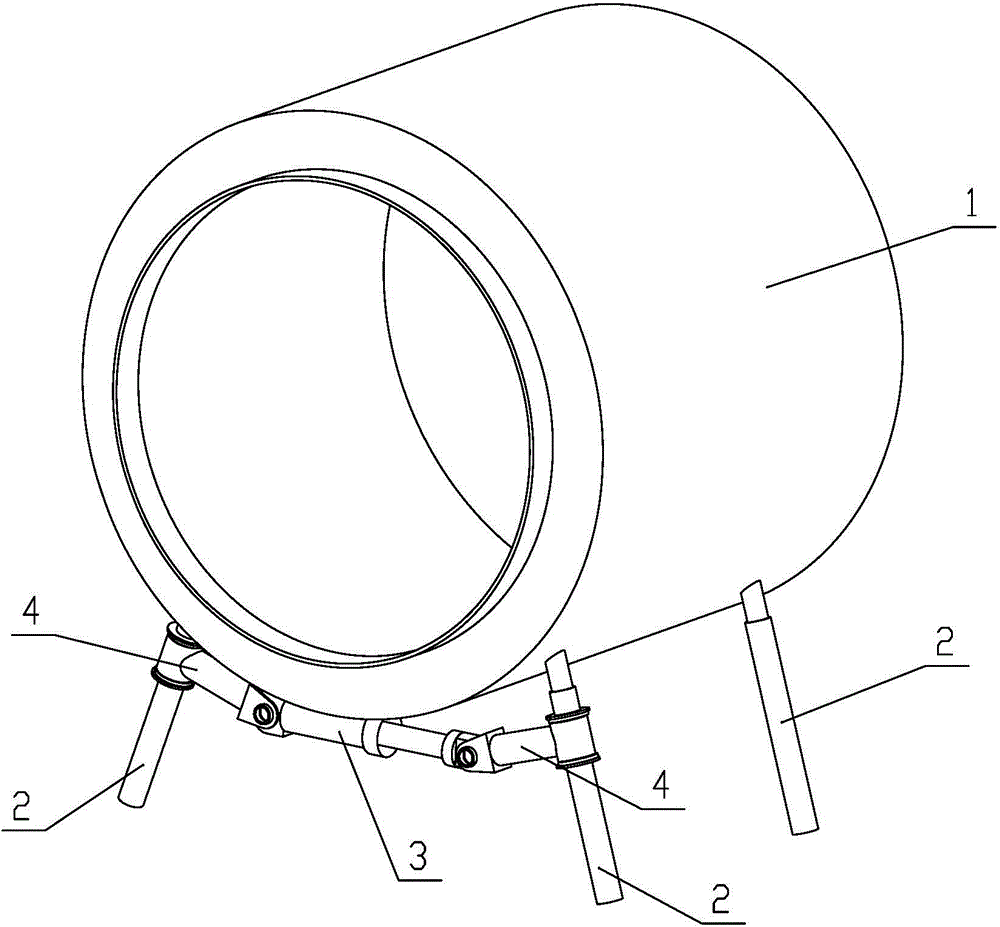

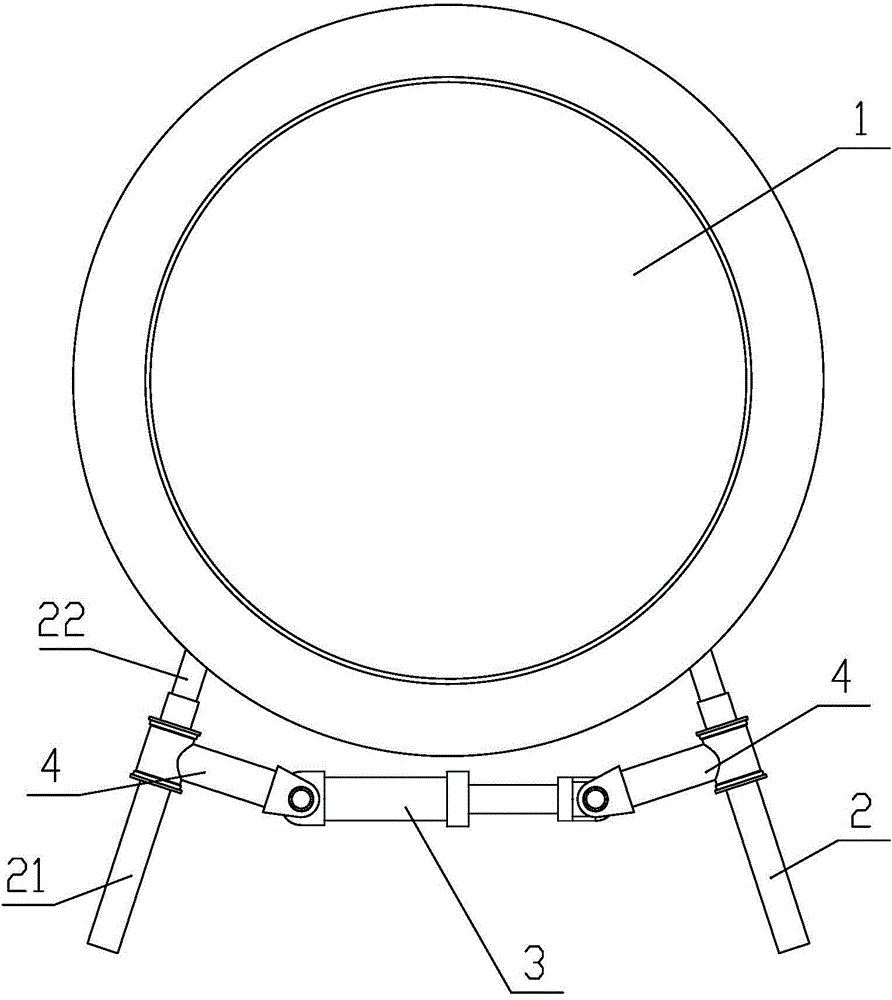

[0033] In this embodiment, a drum washing machine is taken as an example to describe the damping mechanism in detail. Such as Figure 1 to Figure 3 As shown, the damping mechanism includes two pairs of four first shock absorbers 2 arranged on the front and rear of the outer tub 1 of the washing machine, respectively, and two pairs of first shock absorbers 2 arranged on both sides of the lower part of the outer tub 1, and two first shock absorbers at the front 2 is connected with a second shock absorber 3.

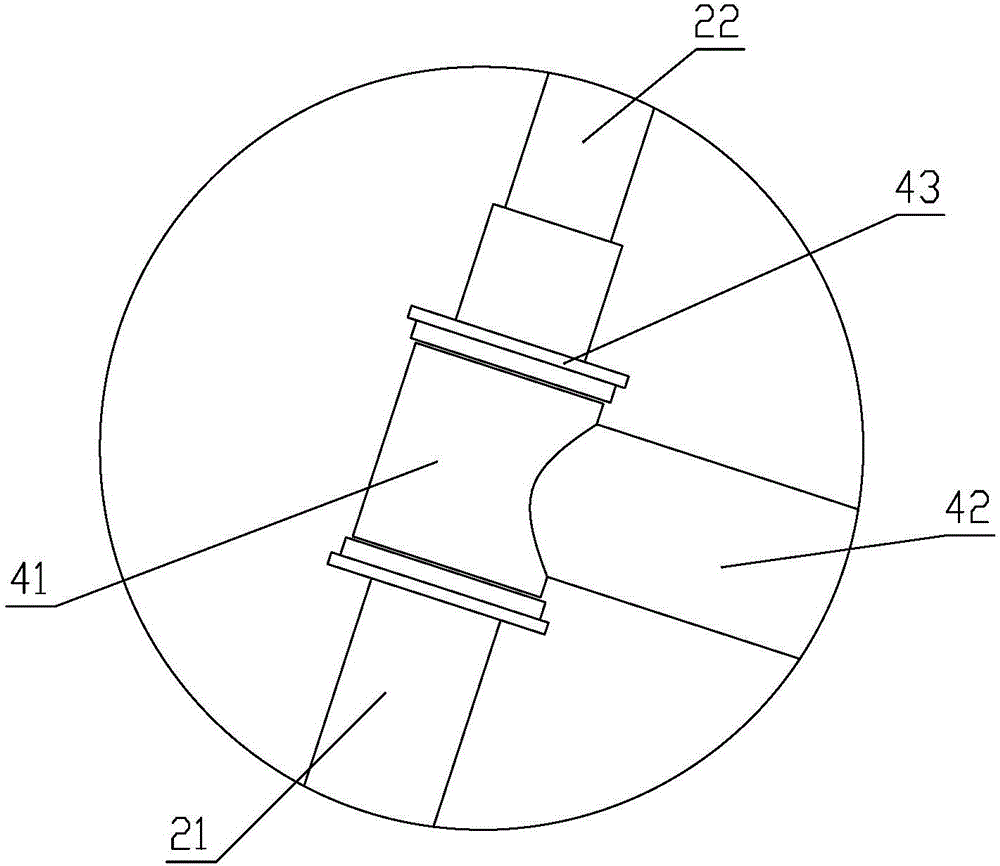

[0034] Wherein, the lower end of the first shock absorber 2 is connected to the shell of the washing machine, and the upper end is connected to the outer cylinder 1 . Both ends of the second shock absorber 3 are connected to the first shock absorber 2 through connecting pieces 4 . The connecting member 4 includes a sleeve 41 sleeved on the first shock absorber 2 and a connecting rod 42 fixedly connected to the side wall of the sleeve 41. The free end of the connecting rod...

Embodiment 2

[0043] This embodiment provides a washing machine, which has the shock absorbing mechanism as described in Embodiment 1, and has good shock absorbing effect, low noise, large volume, light weight and more compact structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com