Device for preparing biogas through plant straw degradation and anaerobic fermentation and application method

A plant straw and anaerobic fermentation technology, applied in the field of waste resource utilization, can solve the problems of high cost, low gas production rate, and difficulty in popularization, and achieve the effects of high gas production rate, large processing capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

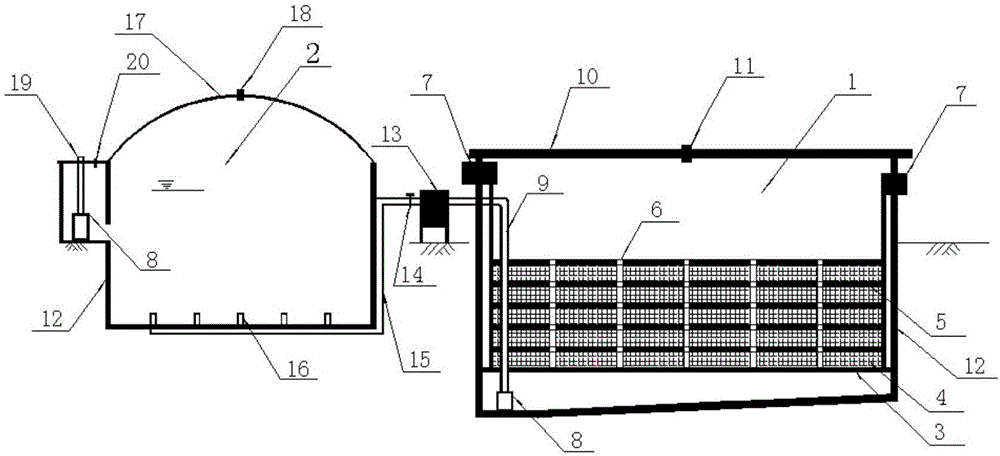

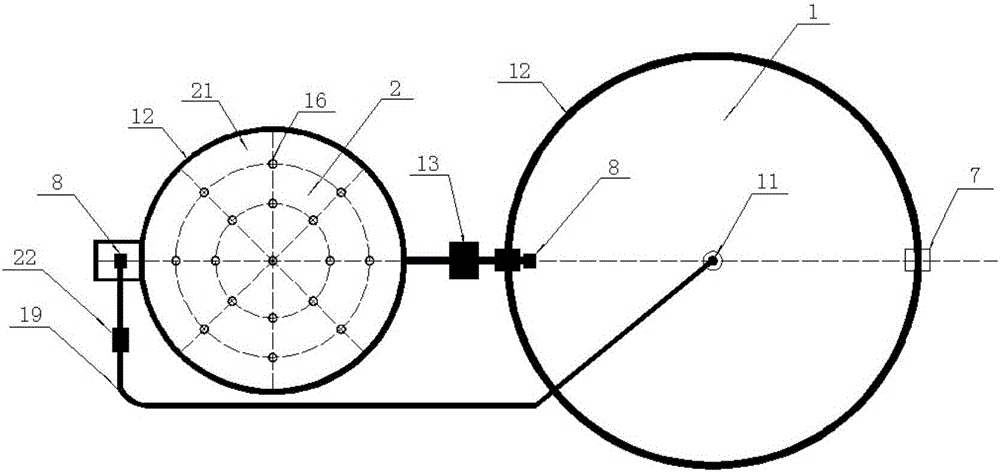

[0021] Example 1: Preparation of biogas from corn stalks

[0022] like figure 1 and figure 2 As shown, the degradation tank 1 and the fermentation tank 2 are prepared, and the volume of the degradation tank 1 is 70m 3 , the volume of fermentation tank 2 is 52.5m 3 The plant straw 4 is corn straw; the lifting vibrator 7 is set on the wall 12 of the degradation tank 1, and the plant straw 4 and human and animal manure 5 are layered on the support rod 3, and the degrading bacteria are mixed in at the same time. The slag channel 6, by extracting the biogas slurry in the fermentation tank 2, circulates to the ventilation liquid spray port 11 on the top cover plate 10 of the degradation tank 1 and sprays the biogas slurry to adjust the humidity of the corn stalks and human and animal manure 5; The material is transported to the fermentation tank 2 for anaerobic fermentation to prepare biogas through the filter 8, the feed pipe 9, the slag discharge pump 13, the discharge main pi...

example 2

[0030] Example 2: Biogas Production from Rice Straw

[0031] like figure 1 and figure 2 As shown, the degradation tank 1 and the fermentation tank 2 are prepared, and the volume of the degradation tank 1 is 15m 3 , the volume of fermentation tank 2 is 8.25m 3 , the plant straw 4 adopts straw.

[0032]The bottom plate of the degradation tank 1 is a rectangle with a side length of 1.0m at the filter 8 position, and all the other positions are set into a slope shape, and its slope is 20°. The filter 8 position is the bottom of the slope, and a layer of glass is laid on the upper bottom surface of the whole bottom; The filter 8 screen aperture in the degradation tank 1 is 15mm, and the inner diameter of 9 holes of the feed pipe is 80mm, and the ventilation and slag discharge channel 6 of stockpiling is 200mm wide; the filter screen is set on the support rod 3, and its aperture is 20mm, 3. The minimum distance from the bottom plate of the degradation tank 1 is 0.3m; the ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com