Beer spoilage bacterium inhibitor and application thereof

A technology of antibacterial agent and spoilage bacteria, which is applied in the field of microbial fermentation engineering, can solve problems such as increased viscosity of beer, achieve the effects of improving safety and quality stability, and improving safety and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Traditional beer fermentation process:

[0026] In the wort with a concentration of 12.0°P, according to 1.5×10 7 The inoculum amount of cells / mL was inserted into Saccharomyces pastorianus, and fermented at 12°C. When the diacetyl content dropped to 0.05 mg / L, the temperature was lowered to 0°C, and the wine was stored for 15 to 20 days. Diatomite filtration, cardboard or membrane filtration to obtain sake, dilute the sake with sterile deoxygenated water to make the original wort concentration of beer 8 ~ 12°P to obtain diluted beer, then fill and pasteurize (65°C Sterilize for 30 minutes) promptly make the finished beer of fermentation degree 80%, total acid 1.85mL / 100mL, alcoholic strength 3.3% (v / v).

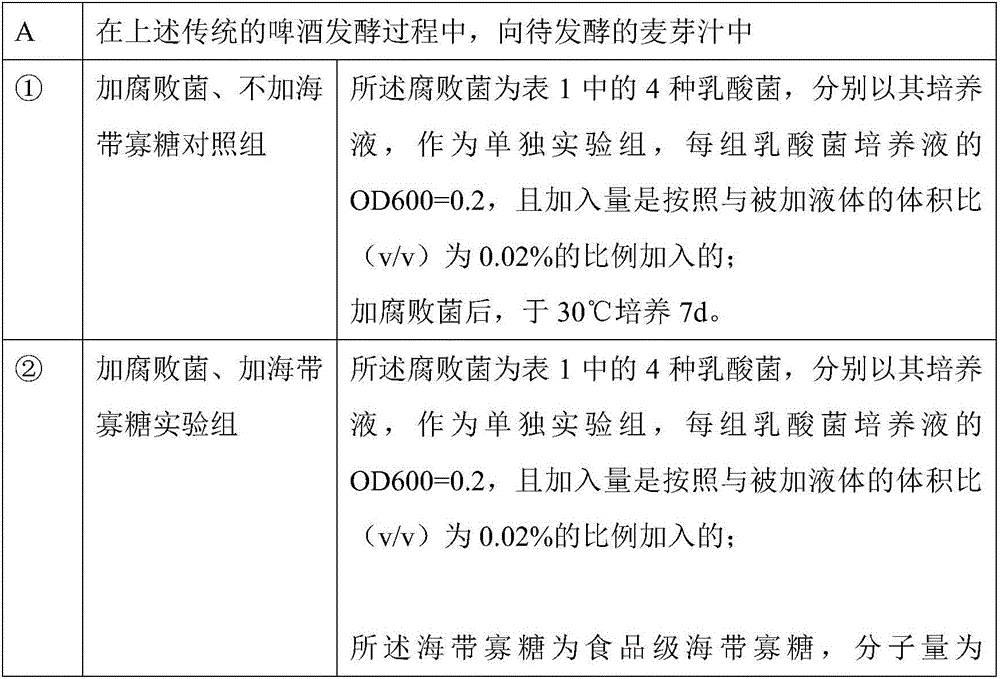

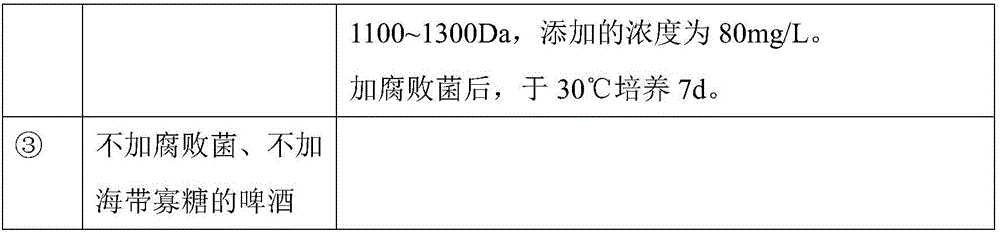

[0027] In order to verify the antibacterial effect of kelp oligosaccharides, the application set up multiple experimental groups, respectively:

[0028]

[0029]

[0030]

[0031]

[0032]

[0033] For each of the above groups, samples were taken to m...

Embodiment 2

[0048]The test results of the group A experiment were: the beer turbidity, color, total organic acids and total biogenic amines of the control group increased significantly, while the pH, total esters and total higher alcohols slightly decreased. Adding 70-90mg / L laminar oligosaccharides (molecular weight 1100-1300Da) to the wort to be fermented by beer can effectively inhibit beer spoilage bacteria, and the bacteriostatic rate can reach 98-100% for experimental bacteria. There was no significant difference in normal beer.

[0049]

[0050] The test results of the group B experiment were: the beer turbidity, color, total organic acids and total biogenic amines of the control group increased significantly, and the pH, total esters and total higher alcohols slightly decreased. Adding 50mg / L kelp oligosaccharide (molecular weight 900-1100Da) to the wort to be fermented by beer can effectively inhibit beer spoilage bacteria, and the bacteriostatic rate can reach 98-100% for exp...

Embodiment 3

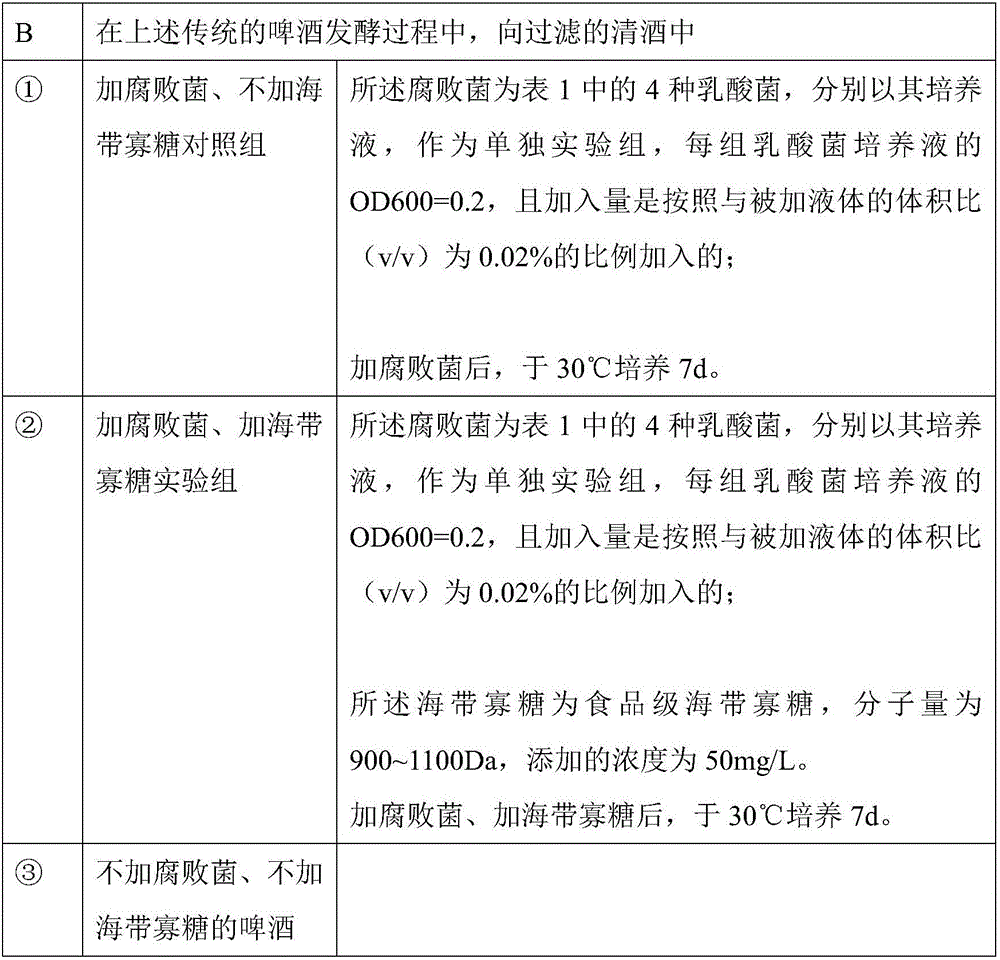

[0056] Take the black lion beer produced by China Resources Snow Beer (Dalian) Co., Ltd. to repeat the above experiment. This beer has an original wort concentration of 9.0°P and an alcohol content of 3.6% (v / v). Beers with other wort concentrations and alcohol degrees can also be selected. , such as cooked beer, draft beer, draft beer, pale beer, dark beer, dark beer, dry beer, low alcohol beer and wheat beer, etc.

[0057] Add contaminating bacteria and kelp oligosaccharide bacteriostatic agent to the above-mentioned finished wine, and take the wine that adds polluting bacteria and does not add kelp oligosaccharide bacteriostatic agent as a control, as follows:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com