Oily wastewater treatment device

A technology for treating device and wastewater, applied in the field of environmental protection, can solve the problems of difficult and difficult treatment of oily wastewater, and achieve the effects of oil-water separation and grading treatment, good treatment effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

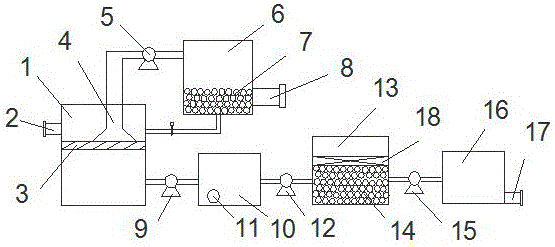

[0010] Such as figure 1 A treatment device for oily waste water shown includes a waste water collection tank 1, a water inlet 2 is provided on the side wall of the waste water collection tank 1, an oil baffle 3 is provided inside, and an oil suction pipe 4 is provided on the top of the waste water collection tank 1, and the oil suction pipe 4. Connect the oil residue adsorption tank 6 through the oil pump 5, the bottom of the oil residue adsorption tank 6 is provided with a filler 7, and the side wall is provided with a drain port 8; the waste water collection tank 1 is connected to the sedimentation tank 10 through the No. There is a slag outlet 11 at the bottom, and the sedimentation tank 10 is connected to the anaerobic reaction tank 13 through the No. pool 16, the side wall of clear water pool 16 is provided with water outlet 17, and described oil residue adsorption pool 6 is connected back to wastewater collection pool 1 through pipeline, and baffle plate 18 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com