Elevator guide rail fixing part for high-speed and high-rise elevator car

A technology for elevator guide rails and high-rise elevators, applied in elevators, transportation and packaging, etc., can solve problems such as elevator guide rail displacement, safety accidents, elevator safety accidents, etc., to ensure damage and accuracy, prevent bumps, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

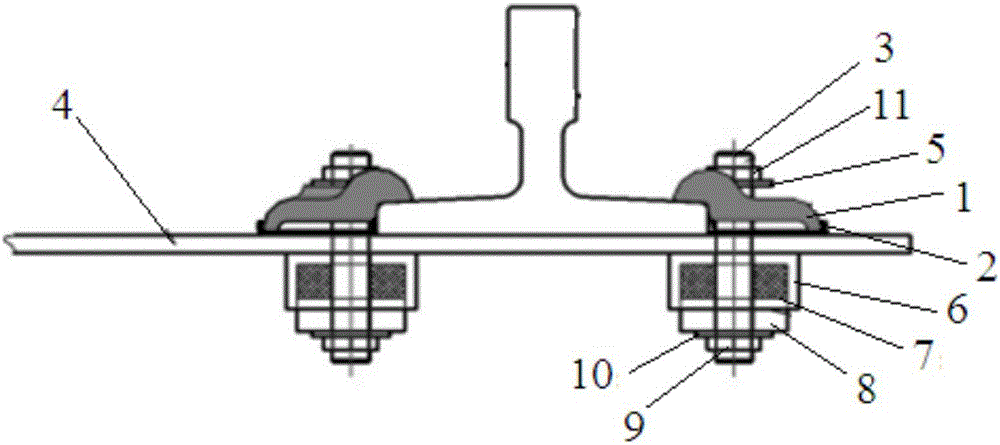

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

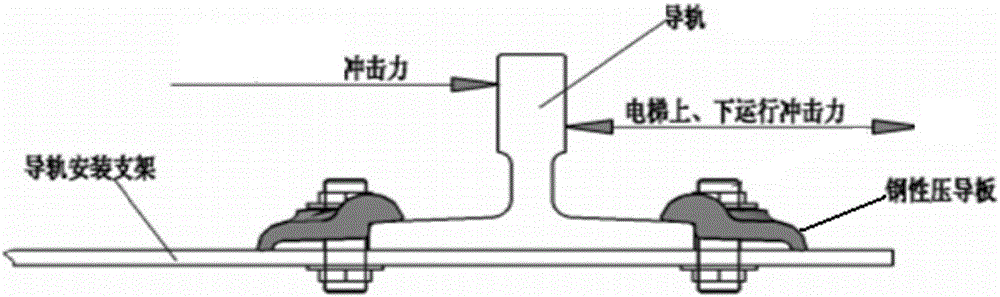

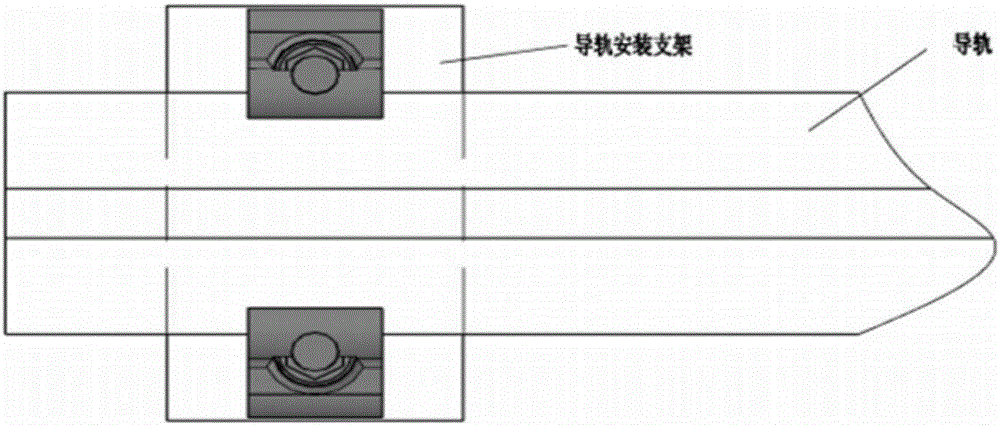

[0031] Such as image 3 and figure 2 , 4 As shown, the elevator guide rail fixing part for high-speed and high-rise elevator cars of the present invention includes a pressure guide plate 1 that is crimped on the guide rail vanes on both sides of the elevator guide rail, and one end of the pressure guide plate 1 is crimped on the corresponding side. The bottom of the pressure guide plate 1 is provided with a positioning plate 2, one side of the positioning plate 2 is against the outer edge of the corresponding side guide rail blade, and the other side of the positioning plate 2 is upward The other end of the pressure guide plate 1 is pressed against the inner side of the tilted side of the positioning plate 2. If the thickness of the elevator guide rail guide rail blade is thicker, the positioning plate 2 is against the outer edge of the corresponding side guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com