Multifunctional cable guider

A cable conductor and multi-functional technology, which is applied in the field of multi-functional cable guides, can solve the problems of easy tipping of twisted cables, inaccurate measurement, and low work efficiency, and achieves easy observation and recording, scientific and reasonable structure, and easy to use Convenient and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

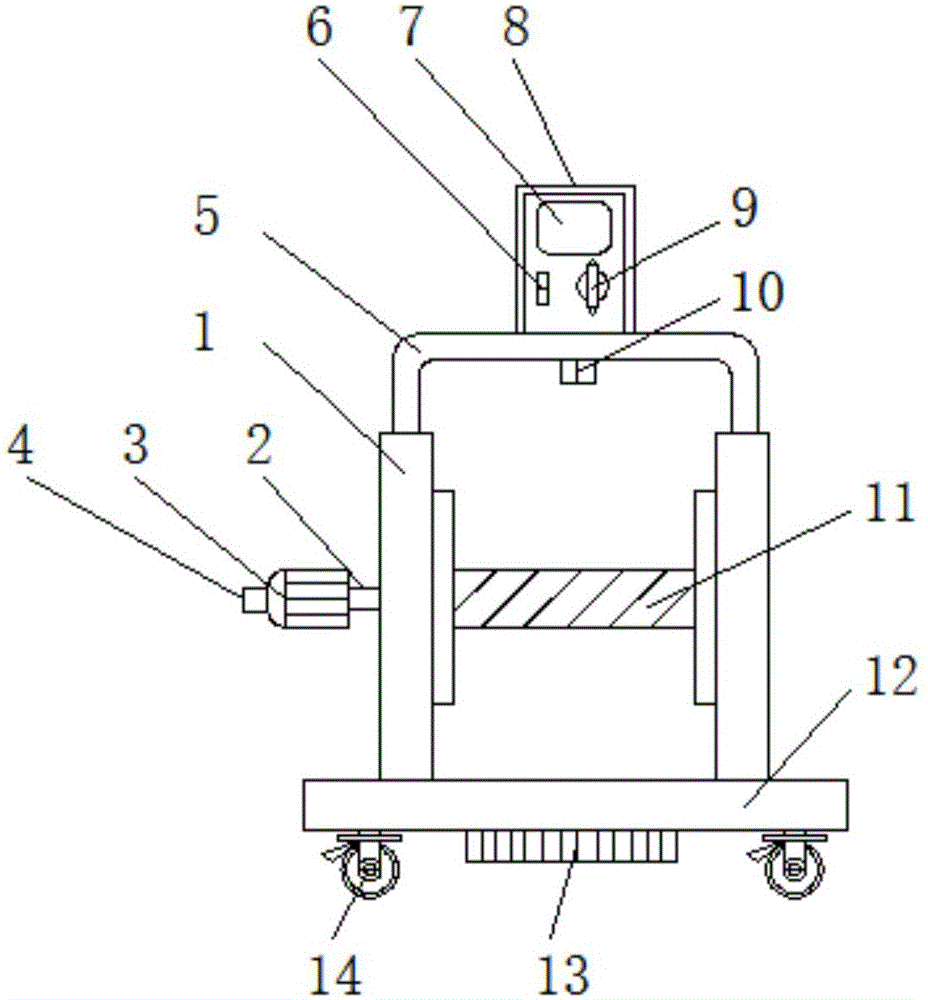

[0017] see Figure 1-2 , an embodiment provided by the present invention: a multifunctional cable guide, including a speed regulator 9 and a support base 12, the support base 12 is equipped with a guide support column 1, and a cable is installed between the guide support columns 1 The collection drum 11, and the left side of the wire guide support column 1 is equipped with a drive motor 3, a motor controller 4 is installed on the drive motor 3, and the drive motor 3 is connected with the cable collection drum 11 through the rotating main shaft 2, and the wire guide support column 1 A fixed frame 5 is installed on the top of the fixed frame 5, and a control box 8 is installed on the fixed frame 5. An LED liquid crystal display 7 and a start button 6 are installed on the front wall of the control box 8, and the start button 6 is located under the LED liquid crystal display 7. Control The inside of casing 8 is equipped with digital-to-analog converter 15, ARM processor 16 and cir...

Embodiment 2

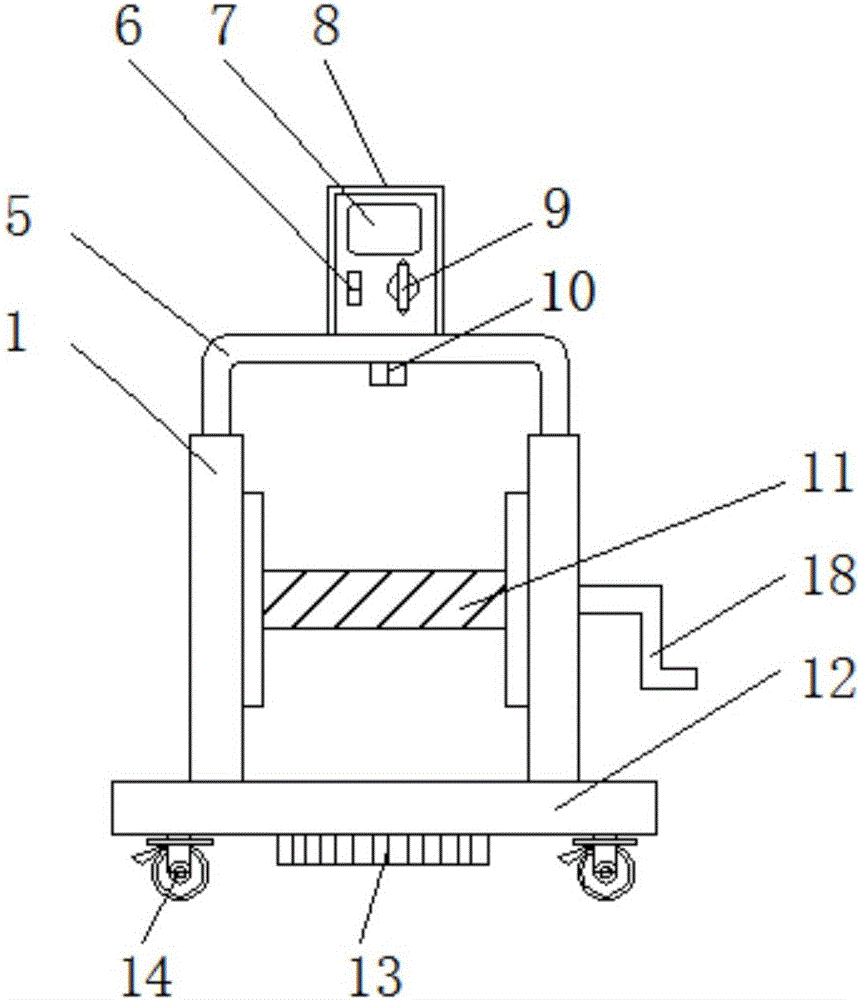

[0019] see image 3 , and the difference from the first embodiment is that: the right side of the wire guide supporting column 1 is equipped with a handle 18 .

[0020] Specific use method: in the work of the present invention, open the start button 6 on the front wall of the control box 13, the drive motor 3 starts to work, and the drive motor 3 is connected with the cable collection drum 11 through the rotating main shaft 2, so that the cable collection drum 11 is connected to the cable Collect, when opening start button 6, timer 10 starts counting, and speed regulator 9 controls drive motor 3 to rotate at a constant speed, by the time used by the rotation speed of drive motor 3 shown on LED liquid crystal display 7 and timer 10 , the specific length of the cable collected by the cable collection drum 11 can be calculated, which improves the practicability of the cable guide; when the drive motor 3 fails, according to the second embodiment, the cable is collected by manually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com