Polyimide (PI) pipe cutting machine

A technology of cutting machine and casing, which is applied in the direction of metal processing, etc., can solve the problems of uneven cutting edges, easy burrs, and difficult size adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

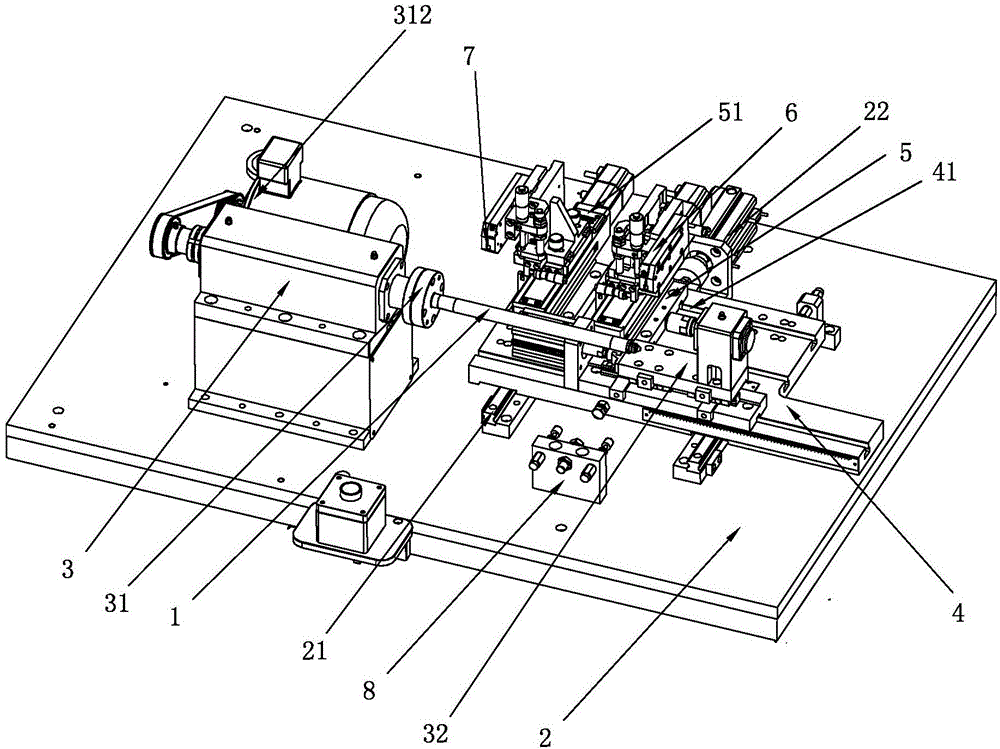

[0021] see figure 1 , a PI pipe cutting machine of the present invention includes a workbench 2 and a clamping mechanism 3 for clamping the workpiece 1 and driving the workpiece 1 to rotate. The workbench 2 is also provided with a first Y-axis slide rail 21 and A base cylinder 22, a base 4 is slidably installed on the first Y-axis slide rail 21, an X-axis guide groove 41 is provided on the base 4, and at least one set of tool rest bases are slidably installed in the X-axis guide groove 41 5. The knife rest base 5 is provided with a Y-axis electric sliding table 51 on which a knife rest 6 is slidably installed, and a blade 7 is mounted on the knife rest 6 .

[0022] see further figure 2 , the tool post 6 includes a tool post body 61, a base plate 62 slidably mounted on the Y-axis electric slide table 51 and a fixture 63 for fixing the blade 7, the base plate 62 is provided with a first X-axis slide rail 621, the second An X-axis slide rail 621 is also provided with a threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com