Novel planer type milling machine device of improved structure

A gantry milling machine, a new type of technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of untimely discharge of iron chips, poor protection effect, etc., to reduce processing costs, facilitate processing, and speed up The effect of chip evacuation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

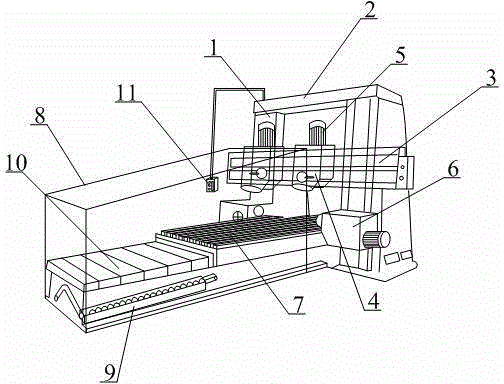

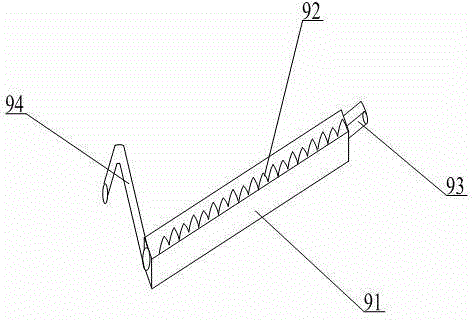

[0024] Such as Figure 1 to Figure 3 As shown: the present invention provides a new improved structure of the gantry milling machine device, including a support column 1, an upper plate 2, a transverse guide rail 3, a transmission box 4, a motor 5, a control box 6, a workbench 7, a shield 8, and chip removal The device 9 and the telescopic plate 10, the upper plate 2 is arranged on the upper part of the support column 1; the described transverse guide rail 3 is arranged in the middle of the front part of the support column 1; the described transmission box 4 is fixed on the upper part of the transverse guide rail 3 The motor 5 is fixed on the top of the transmission box 4; the workbench 7 is set on the top of the support column 1; the shield 8 is set on the top of the workbench 7; the chip removal device 9 is set On the left side of the lower part of the workbench 7; the telescopic plate 10 is arranged on the upper part of the chip removal device 9.

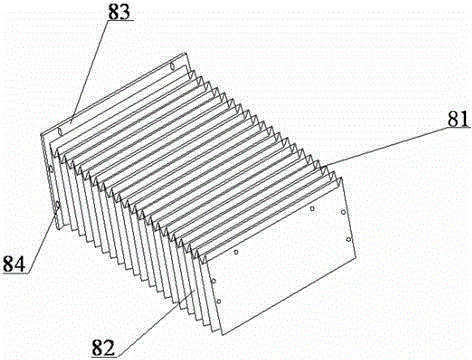

[0025] The shield 8 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com