Gas Powered Ultrasonic Multiphase Mixer

A multi-phase mixing and gas-powered technology, applied in fire rescue and other directions, can solve the problems of difficult gas-liquid-solid three-phase mixing, limited enhancement of gas-liquid mixing effect, and no limited core component - mixer structure, etc. The effect of reducing the mass ratio, broadening the effective working range, improving the effect of atomization and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

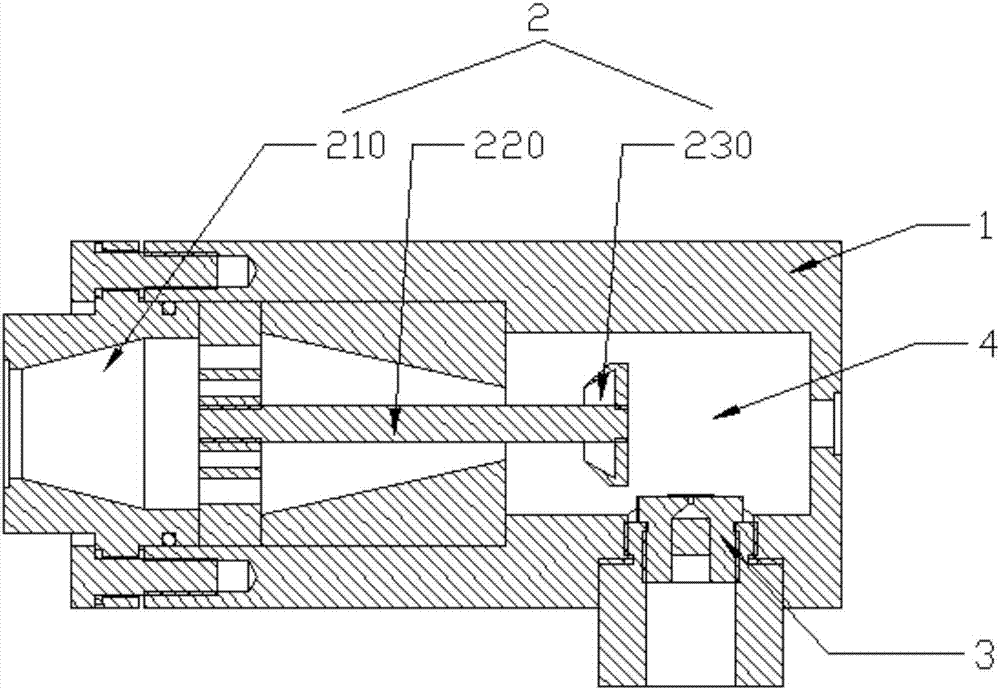

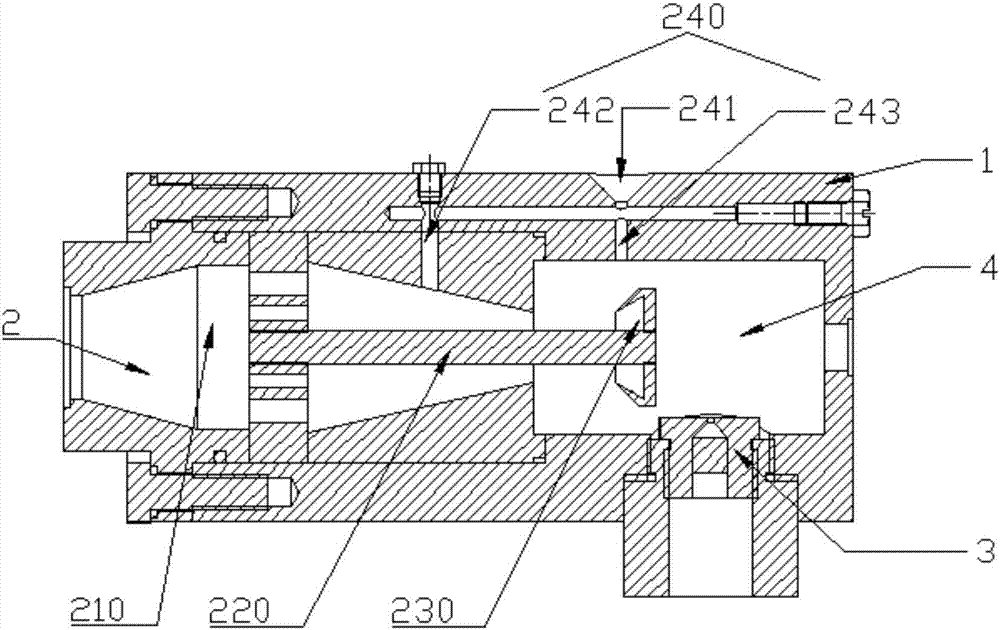

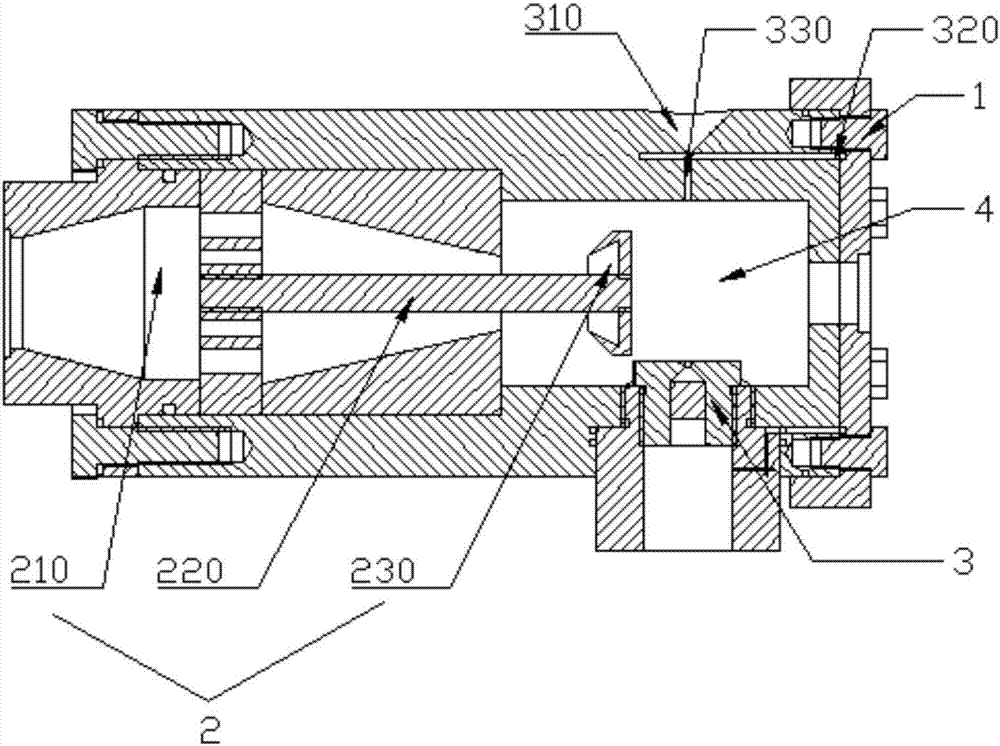

[0040] Such as Figure 1~3 As shown, the present invention provides a kind of aerodynamic ultrasonic multiphase mixer, comprising:

[0041] subject1;

[0042] The gas drainage cavity 2 is arranged inside the main body 1. The gas drainage cavity 1 is used to introduce the gas passing in the horizontal direction and accelerate the gas to generate ultrasonic waves through resonance, wherein the gas drainage cavity 2 includes:

[0043] A guide chamber 210, which is used to guide the gas passing in the horizontal direction to accelerate after entering, and the guide chamber 210 is connected to the mixing chamber;

[0044] a central rod 220, one end of which is fixed in the guide cavity; and

[0045] A resonant cavity 230, which is fixed to the other end of the central rod 220, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com