Water soluble mineral powder fired from shellfish and/or accretionary limestone and preparation method and application thereof

A limestone, water-soluble technology, applied in the field of water-soluble mineral powder and its preparation, can solve the problems of complex production process and cannot be used for food, etc., and achieves the effects of simple equipment, improved health and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

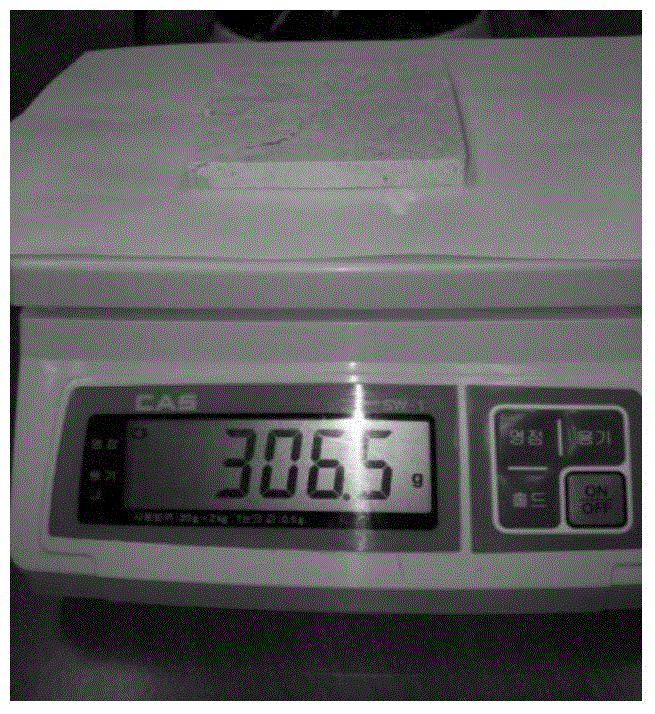

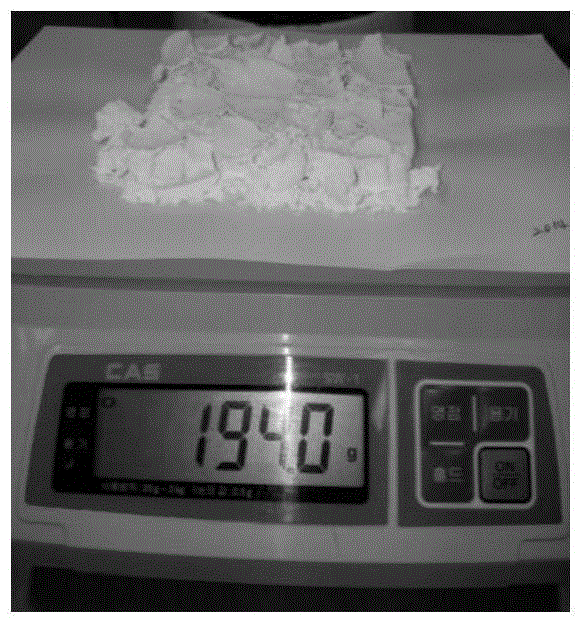

[0056] The water-soluble mineral powder in Example 1 of the present invention is obtained by natural weathering after segmental calcination in the temperature range of 0°C to 990°C, using shells as raw materials; it contains dissolved hydrogen, wherein every 100g of water-soluble mineral The calcium content in the powder reaches 68.85g. The shells are oyster shells.

[0057] Its preparation method is as follows:

[0058] Step 1. Pick the shell raw materials, process the raw materials, place them in the oven of the firing furnace, and place the oven in the firing furnace;

[0059] Step 2. In order to remove the carbon dioxide contained in the raw material, the temperature is raised to 500°C after 5 hours;

[0060] Step 3. In order to remove the arsenic contained in the raw material, the temperature is raised from 500°C to 800°C after 5 hours;

[0061] Step 4. Continue to keep warm at 800°C for 5 hours;

[0062] Step 5, heating up to 990° C. after 5 hours;

[0063] Step 6. ...

Embodiment 2

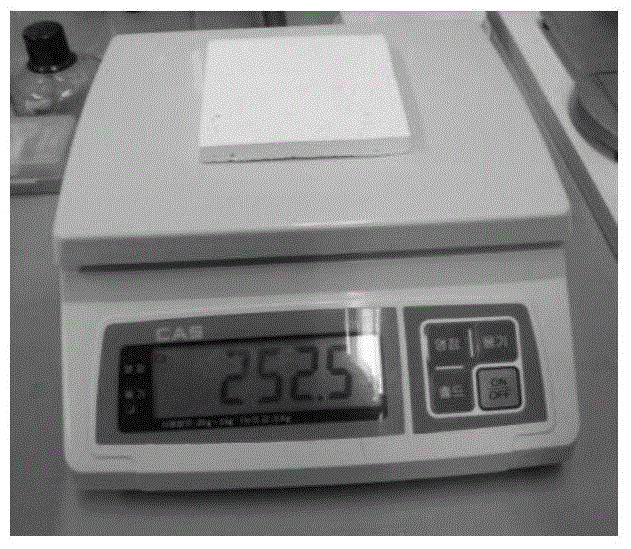

[0076] The water-soluble mineral powder in Example 2 of the present invention is obtained by natural weathering after segmental calcination in the temperature range of 0°C to 990°C using the accumulated coral limestone grown in clean sea areas as raw material; it contains dissolved hydrogen, Among them, the calcium content in every 100g of water-soluble mineral powder reaches 54.72g.

[0077] Its preparation method is as follows:

[0078] Step 1. Picking and accumulating coral limestone raw materials, processing the raw materials to obtain blocks, and then placing them in the oven of the firing furnace, and placing the oven in the firing furnace;

[0079] Step 2. In order to remove the carbon dioxide contained in the raw material, the temperature is raised to 500°C after 5 hours;

[0080] Step 3. In order to remove the arsenic contained in the raw material, the temperature is raised from 500°C to 800°C after 5 hours;

[0081] Step 4. Continue to keep warm at 800°C for 5 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com