Half-wrapped ultrathin liquid-absorption core body and making method

A production method and technology for absorbent cores, which are applied in the fields of absorbent pads, medical science, clothing, etc., can solve the problems such as the inability to realize the production and cutting of composite non-woven cores, the inability to be covered by polymer resin, and the discomfort of users. , to achieve the effect of improving production efficiency, reducing thickness and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

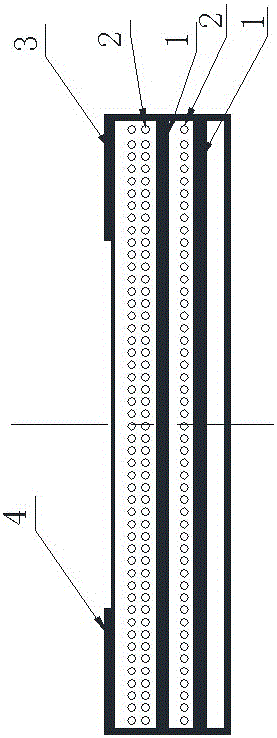

[0011] Example 1: Refer to the attached figure 1 . A semi-packed ultra-thin liquid-absorbent core body, comprising a covering layer 4 on which is provided with one or more layers of puffed non-woven fabric and polymer water-absorbing resin distributed on the puffed non-woven fabric The liquid-absorbing layers 1 and 2 are superimposed, the covering layer 3 is located on the liquid-absorbing layer, and the covering layer 4 is folded on the edge of the covering layer 3 to form a half-packed ultra-thin liquid-absorbing core, which is thermally pressed or ultrasonically welded. The thickness of SAP applied to each layer of puffed non-woven fabric surface depends on the size of liquid absorption.

[0012] The half-pack of ultra-thin liquid absorbent cores distributed in the composite non-woven fabric are distributed in spacing strips and the spacing part is the bonding and cutting part. The bonding method can be ultrasonic bonding, electric heating fusion bonding, and glue bonding .

Embodiment 2

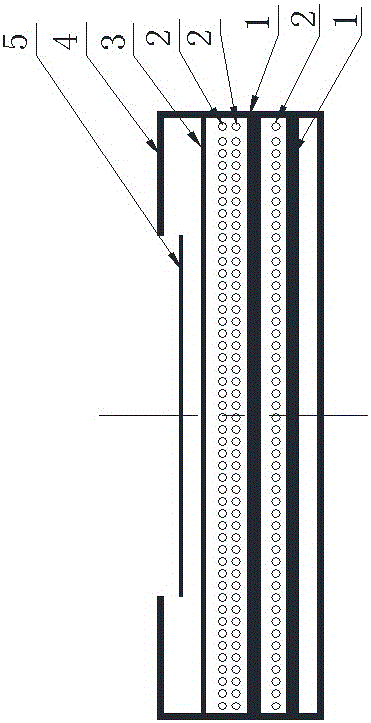

[0013] Example 2: On the basis of Example 1, refer to the attached figure 2 . The cover layer 3 or the cover layer 4 is provided with a guide layer 5, the purpose of which is to accelerate the diffusion and absorption of the liquid. The cover layer 4 is closed on the side of the guide layer 5 to form a half-packed ultra-thin suction Liquid core body.

Embodiment 3

[0014] Example 3: On the basis of Example 1 or 2, there is a small amount of glue on the polymer water-absorbing resin layer between the multilayer puffed non-woven fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com