Home-use sweet potato roasting pan with additional fire gas duct at pan center

A technology of fire, gas channel and baking pan, which is applied in the field of cookware, can solve the problems of low heat transfer efficiency, and achieve the effect of enhancing taste and reasonable heat transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

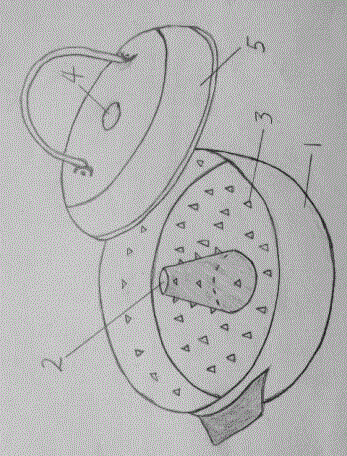

[0007] exist figure 1 In the middle, a fire air channel (2) is added in the center of the sweet potato baking pot (1), and the fire gas carries energy not only from the surroundings of the pot, but also through the fire air channel (2) in the center of the pot, so that the heat transfer path of the baking pan is improved Reasonable, the temperature of relative positions in the pot is more uniform, which enhances the taste of baked sweet potatoes. Some very small cones (3) protrude from the inside of the pot to support the sweet potatoes, so as to prevent the sweet potatoes from directly contacting the pot body and causing a large area of scorching. The central part of the pot cover (5) has an exposure hole (4) matching the fire gas passage, so that the pot cover can just expose the fire gas port of the pot and tightly cover the pot. The present invention adopts primary cast iron or refined iron to make, and the shape of the pot body is not limited to circle and polygon, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com