Electric heat trace production process system

A production process and electric heat tracing technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of difficult access to temperature control and temperature measurement points, leakage and pollution of heating fluid raw materials, and high maintenance costs. Standardized construction process for heat tracing, solving the problem of uniform and accurate temperature control, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

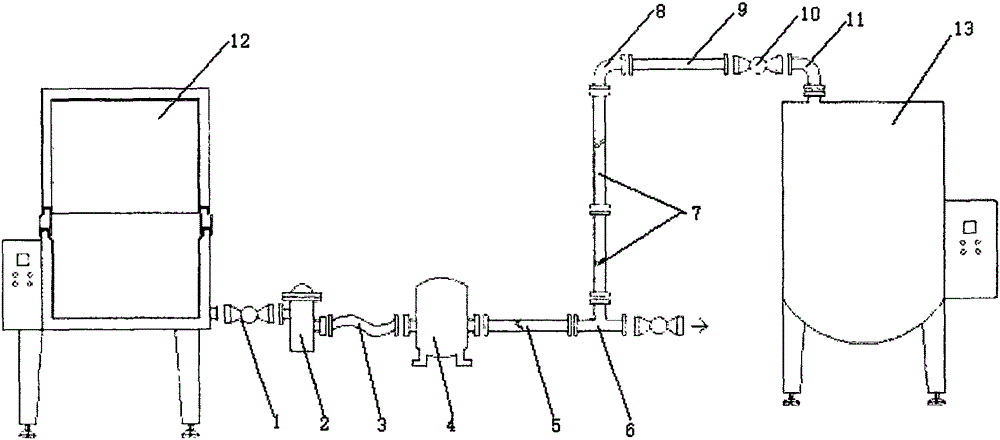

[0014] see figure 1 , an electric heat tracing production process system, comprising a first electric heating valve 1, an electric heating filter 2, an electric heating soft connection 3, an electric heat pump 4, a first electric heating pipeline 5, an electric heating tee 6, a second electric heating pipeline 7, a first An electric heating elbow 8, a third electric heating pipeline 9, a second electric heating valve 10 and a second electric heating elbow 11, one end of the first electric heating valve 1 is connected to an electric heating melting mixing reaction device 12, and the other end of the first electric heating valve 1 is sequentially The electric heating tee 6 is connected through the electric heating filter 2, the electric heating soft connection 3, the electric heat pump 4 and the first electric heating pipe 5. The other end of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com