Anti-electromagnetic silicon steel sheet for wind generator stator

A silicon steel sheet and anti-electromagnetic technology, which is applied in wind power generation, electromechanical devices, electrical components, etc., can solve the problems that silicon steel sheets cannot effectively prevent electromagnetic waves, waste materials, and cannot meet the needs of customers, so as to achieve good electromagnetic shielding performance and reduce Effects of Radiation Contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

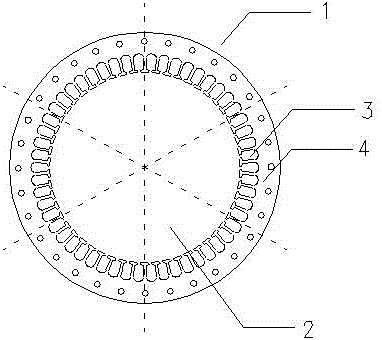

[0017] see figure 1 The invention relates to an anti-electromagnetic silicon steel sheet for a stator of a wind power generator, comprising a silicon steel sheet body 1, the silicon steel sheet body 1 is welded by a plurality of fan-shaped silicon steel sheet units 2 with the same central angle, and the silicon steel sheet unit The inner edge of the 2 is concavely provided with a plurality of wire slots 3, the number of the silicon steel sheet unit 2 is 3 to 8, the number of the 3 wire slots on the silicon steel sheet unit 2 is 10 to 20, and the silicon steel sheet The body 1 is provided with a plurality of circular ventilation holes 4, and the circular ventilation holes 4 surround the center of the silicon steel sheet body 1 to form a single-circle or multi-circle arrangement structure. figure 1 Shown are 32 circular vents arranged in 4 single circles.

[0018] The surface of the silicon steel sheet is coated with an anti-electromagnetic coating, and the anti-electromagnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com