Super capacitor casing

A technology of supercapacitors and shells, applied in the direction of mixed box/shell/package, etc., can solve the problems affecting the assembly and application of the module system, the low one-time pass rate of product capacity, and the low strength of pure aluminum material, so as to improve the one-time pass rate , The effect of improving leakage voltage performance and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

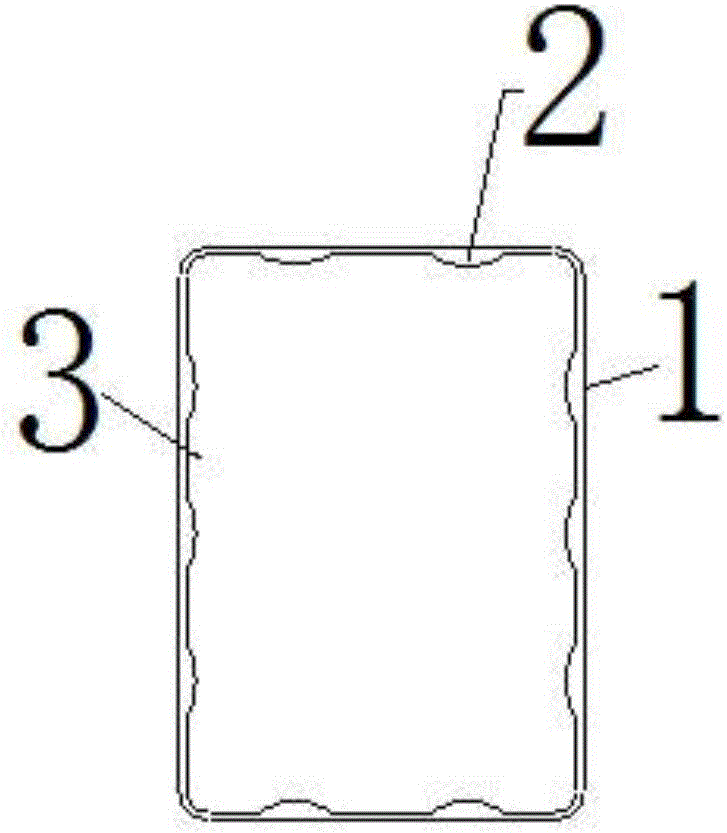

[0022] The supercapacitor casing of the present embodiment includes a casing 1 composed of walls, and the casing 1 is formed with an accommodating space for accommodating solid-liquid phase substances including electrolyte and other structures (including electric core); it also includes reinforcement Rib 2, the reinforcing rib is formed on the wall and protrudes toward the inner space; the junction of the wall and the reinforcing rib also has a guide structure 3, and the guide structure is used for the flow of electrolyte.

Embodiment 2

[0024] The supercapacitor casing of the present embodiment includes a casing 1 composed of walls, and the casing 1 is formed with an accommodating space for accommodating solid-liquid phase substances including electrolyte and other structures (including electric core); it also includes reinforcement Rib 2, the reinforcing rib is formed on the wall and protrudes toward the inner space; the reinforcing rib also has a flow guide structure 3, and the flow guide structure is used for the flow of electrolytic solution.

Embodiment 3

[0026] The supercapacitor casing of the present embodiment includes a casing 1 composed of walls, and the casing 1 is formed with an accommodating space for accommodating solid-liquid phase substances including electrolyte and other structures (including electric core); it also includes reinforcement Ribs 2 and reinforcing ribs are formed on the wall and protrude toward the inner space; the wall also has a flow guide structure 3 on one side of the accommodation space, and the flow guide structure is used for the flow of electrolyte. Such as figure 1 As shown, the ribs 2 are arranged parallel to the groove-type flow guiding structure 3 inside the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com