Resistance paste with high electrothermal conversion rate

A technology of resistive paste and conversion rate, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of high power, enlarged paste pattern area, temperature rise of heating devices, etc., and achieves good printability. , Good adhesion, not easy to fall off

Active Publication Date: 2016-11-16

DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the sustainable development strategy established by our country, the heating elements of electronic components are required to be small in size and high in power. To make more power on the substrate of the same area, it is often necessary to increase the area of the paste pattern, which will inevitably cause The temperature of the heat-generating device itself rises

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

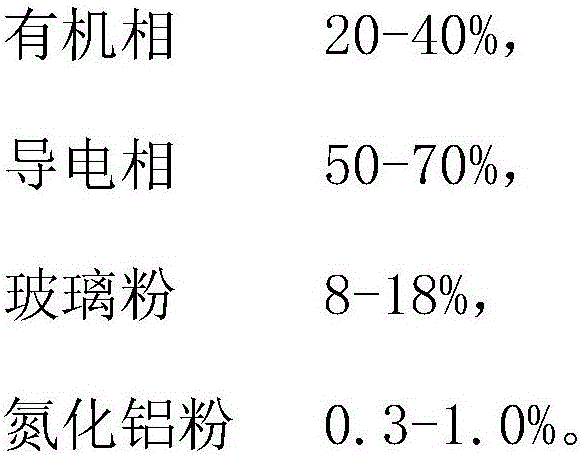

[0016] A resistance paste with high electrothermal conversion rate, by weight percentage, includes the following components:

[0017]

[0018]

Embodiment 2

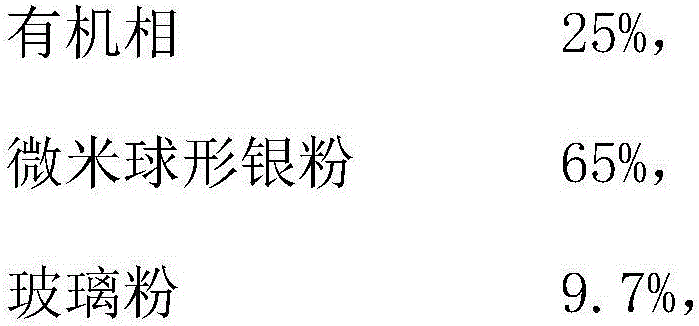

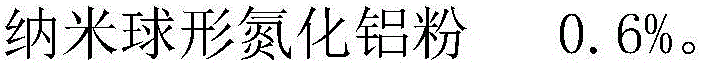

[0020] A resistance paste with high electrothermal conversion rate, by weight percentage, includes the following components:

[0021]

Embodiment 3

[0023] A resistance paste with high electrothermal conversion rate, by weight percentage, includes the following components:

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses resistance paste with high electrothermal conversion rate. The resistance paste comprises the following components in percentage by weight: 20%-40% of an organic phase, 50%-70% of a conductive phase, 8%-18% of glass powder and 0.3%-1.0% of aluminum nitride powder, wherein the organic phase is a mixture of multiple dibasic acid esters; the conductive phase is prepared from one or two of nano / micron flake silver powder and nano / micron spherical silver powder; the glass powder is lead-free glass powder; and the aluminum nitride powder is spherical or fibrous nano powder. The electrothermal conversion rate of the resistance paste disclosed by the invention can reach 95%; the stability is good; the high temperature resistance is excellent; and the resistance paste is good in adhesive force with a base material and does not easily fall off.

Description

Technical field: [0001] The invention relates to the technical field of heating devices, in particular to a resistance paste with high electrothermal conversion rate. Background technique: [0002] In the modern microelectronics industry, people have higher and higher requirements for electronic components, and the production adopts process and standardization to reduce costs. Printed circuit boards are born to meet the needs of the microelectronics industry. In the sustainable development strategy established by our country, the heating elements of electronic components are required to be small in size and high in power. To make more power on the substrate of the same area, it is often necessary to increase the area of the paste pattern, which will inevitably cause The temperature of the heat generating device itself rises. The invention selects nano-aluminum nitride as the thermally conductive functional phase, which can reduce the heat accumulation of the slurry itself...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B1/22

CPCH01B1/22

Inventor 廖玉超苏冠贤

Owner DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com