A kind of t-type ultra-fine thermocouple manufacturing process

A manufacturing process and thermocouple technology, applied in the field of T-type ultra-fine thermocouple manufacturing process, can solve the problems of poor stability, different shapes of thermocouples, high precision requirements, etc., and achieve strong stability, easy promotion and use, Measuring the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

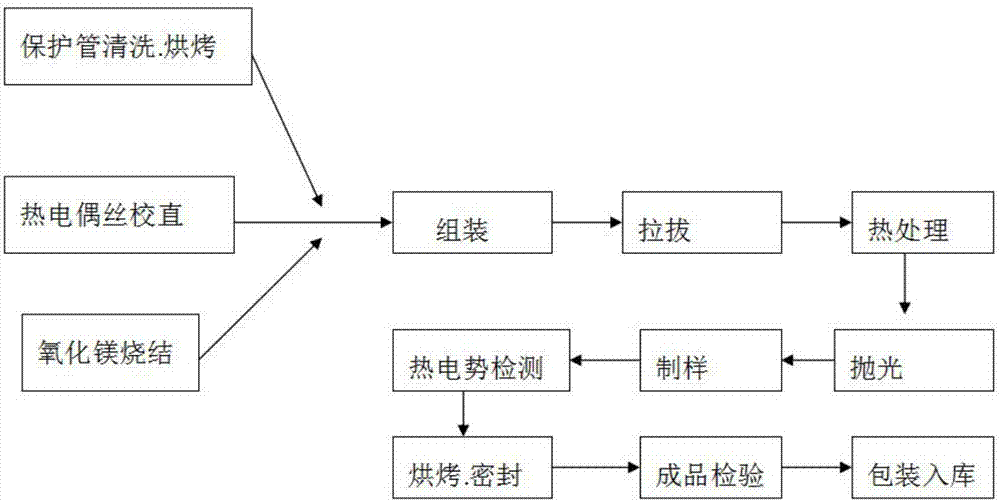

Method used

Image

Examples

Embodiment 1

[0037] A T-type ultra-fine thermocouple manufacturing process, comprising the following steps:

[0038] 1) Take out the armored wire, then use a straightening machine to straighten it, then use a tape measure and pliers to cut the armored wire into the length required by the order, and set aside;

[0039] The processing method of above-mentioned armored wire is:

[0040] a. Take copper-copper-nickel thermocouple wires with a diameter of 2.2 mm for sorting, and select the thermocouple wires with uniform color, smoothness, no oil, no folds, no cracks, no burrs and interlayers, and set them aside;

[0041] b. Take a steel pipe with a diameter of 16mm and a pipe wall thickness of 1.7mm for use;

[0042] c. Choose a magnesium oxide column with a magnesium oxide content ≥ 96%. The magnesium oxide column should be white, free of rust, oil, smooth surface, free of air bubbles, holes, non-eccentric silk holes, and non-bent column body. Reserve;

[0043] d. Place the steel pipe in the...

Embodiment 2

[0066] A T-type ultra-fine thermocouple manufacturing process, comprising the following steps:

[0067] 1) Take out the armored wire, then use a straightening machine to straighten it, then use a tape measure and pliers to cut the armored wire into the length required by the order, and set aside;

[0068] The processing method of above-mentioned armored wire is:

[0069] a. Take copper-copper-nickel thermocouple wires with a diameter of 2.4 mm for sorting, and select the thermocouple wires with uniform color, smoothness, no oil, no folds, no cracks, no burrs and interlayers, and set them aside;

[0070] b. Take a steel pipe with a diameter of 20mm and a pipe wall thickness of 1.9mm for use;

[0071] c. Choose a magnesium oxide column with a magnesium oxide content ≥ 96%. The magnesium oxide column should be white, free of rust, oil, smooth surface, free of air bubbles, holes, non-eccentric silk holes, and non-bent column body. Reserve;

[0072] d. Place the steel pipe in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com