Automatic control system of seedless metering for balanced sugarcane pressing

An automatic control system and nuclear measurement technology, applied in the direction of electrical program control, sequence/logic controller program control, weighing, etc., can solve the problem of rough control, troublesome installation, maintenance and repair of nuclear scales, and inability to accurately control, etc. problems, to achieve the effect of ensuring measurement stability and accuracy, eliminating nuclear radiation hazards, and low application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

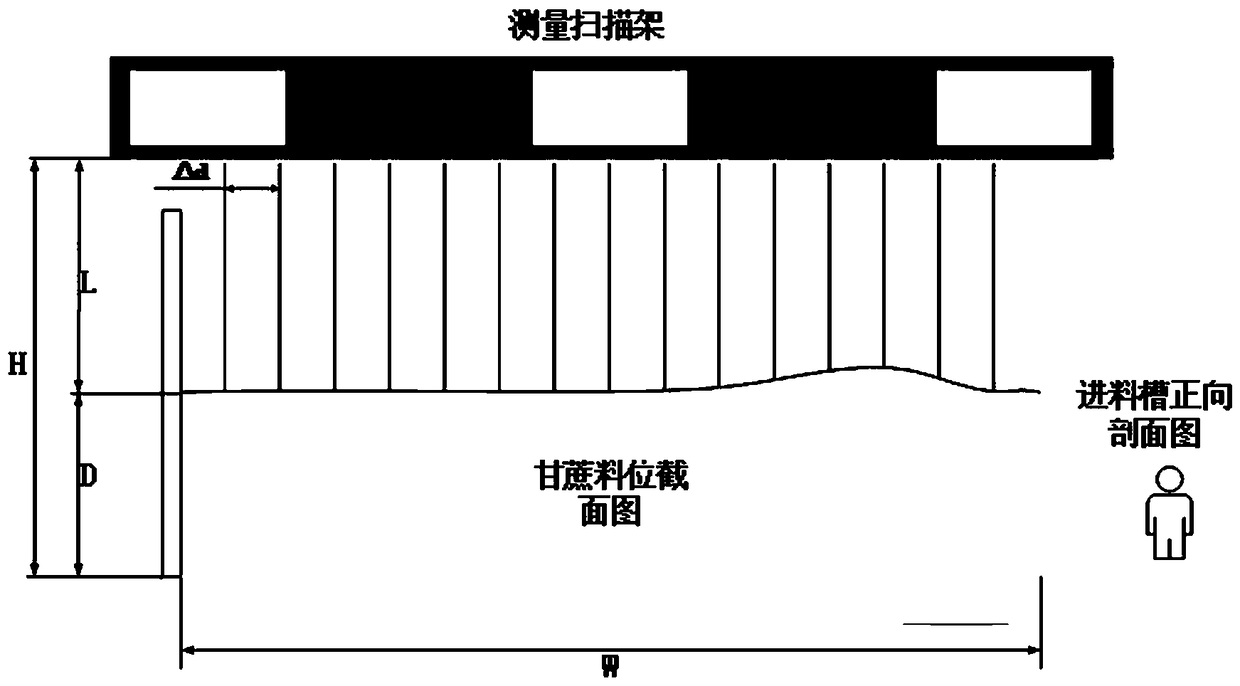

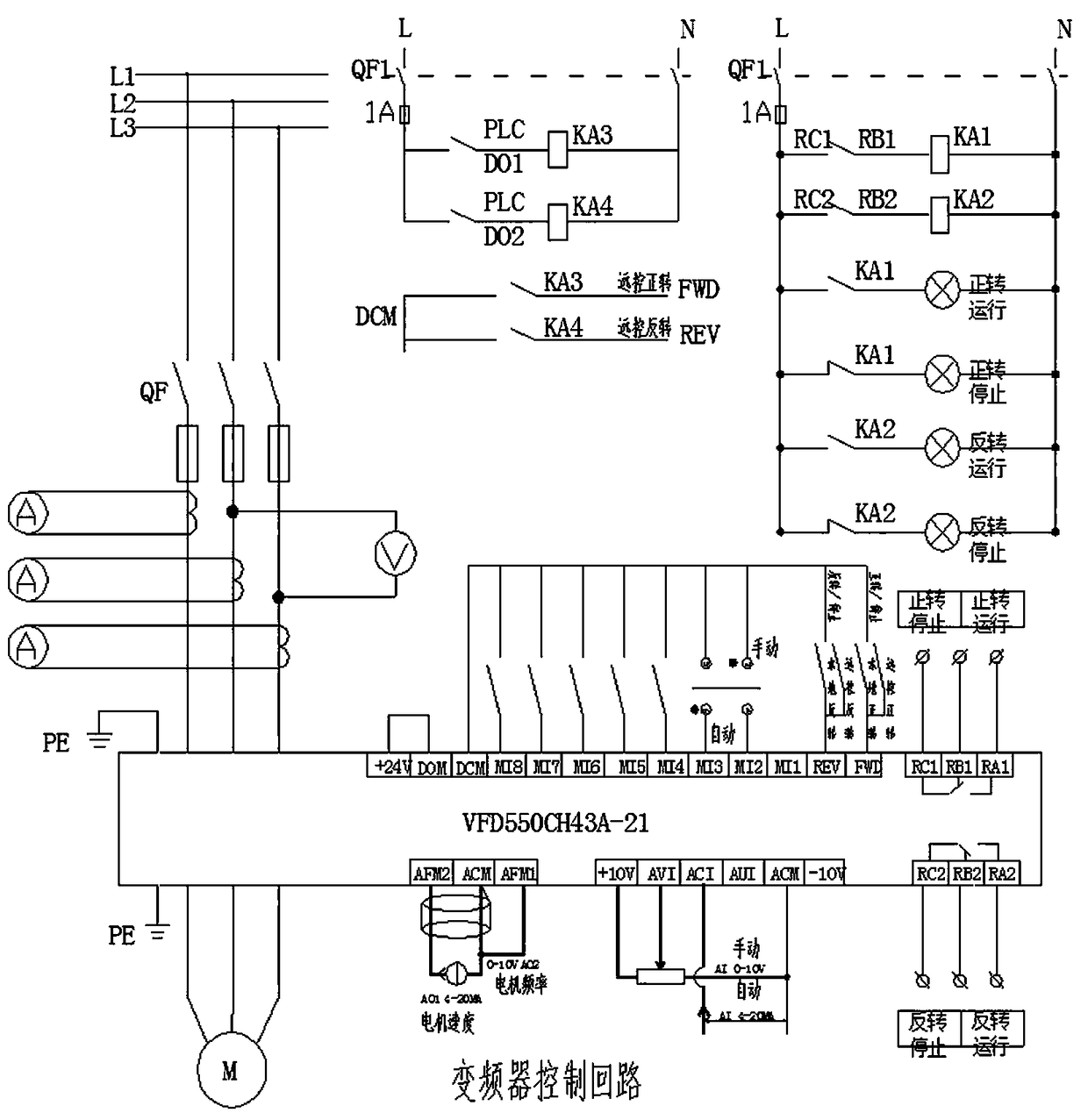

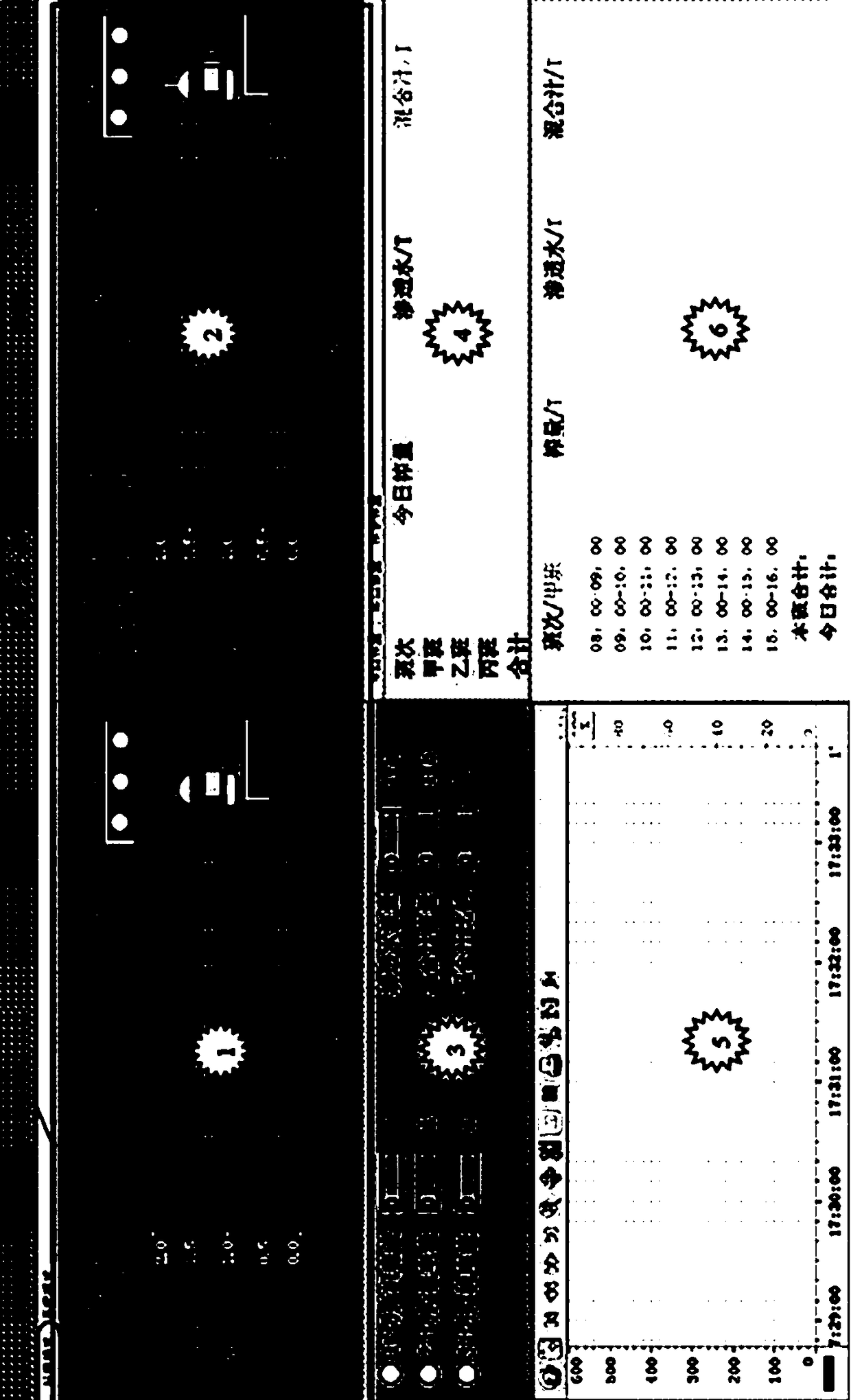

[0068] An automatic control system for sugarcane balanced feeding and non-nuclear metering, which measures and controls the amount of sugarcane feeding by using light wave measurement technology combined with PLC and computer control technology. The system includes a laser distance measuring module, an electrical control module, a PLC control module and The man-machine interface monitoring module; the laser ranging module and the electrical control module are connected with the PLC control module, and the PLC control module is connected with the man-machine interface monitoring module.

[0069] The laser ranging module is provided with a measurement scanning frame above the conveyor belts of the 1# and 2# cane conveying machines, and several groups of laser ranging sensors are built in the measuring scanning frame, and the laser ranging sensors are arranged in a straight line to measure The distance between each point material surface of the chain-belt conveyor trough section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com