A deflector device for high temperature gas

A deflector and high-temperature technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of reducing the service life of gas deflectors, reducing the combat effectiveness of aircraft carriers, and increasing maintenance costs of aircraft carriers, so as to improve the atomization effect , Improve the cooling effect and reduce the impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Carry out the description of specific implementation below in conjunction with accompanying drawing:

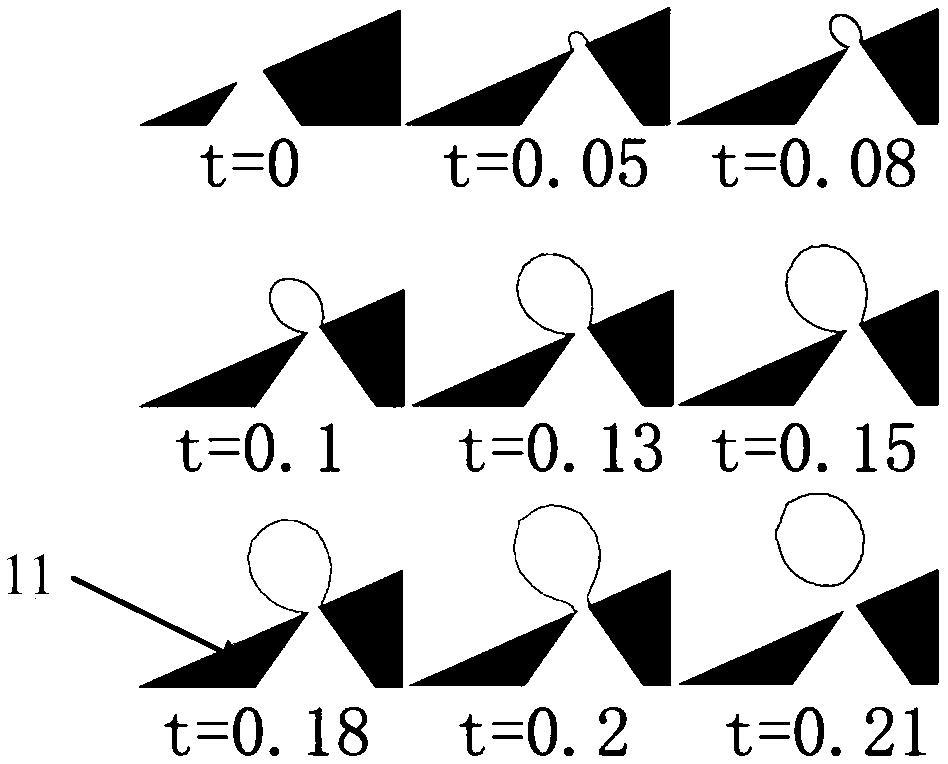

[0029] figure 1 The situation where the liquid is heated and boiled on one of the teeth of the saw-toothed base 11 to generate bubbles is simulated, and the gasification core is given during the simulation.

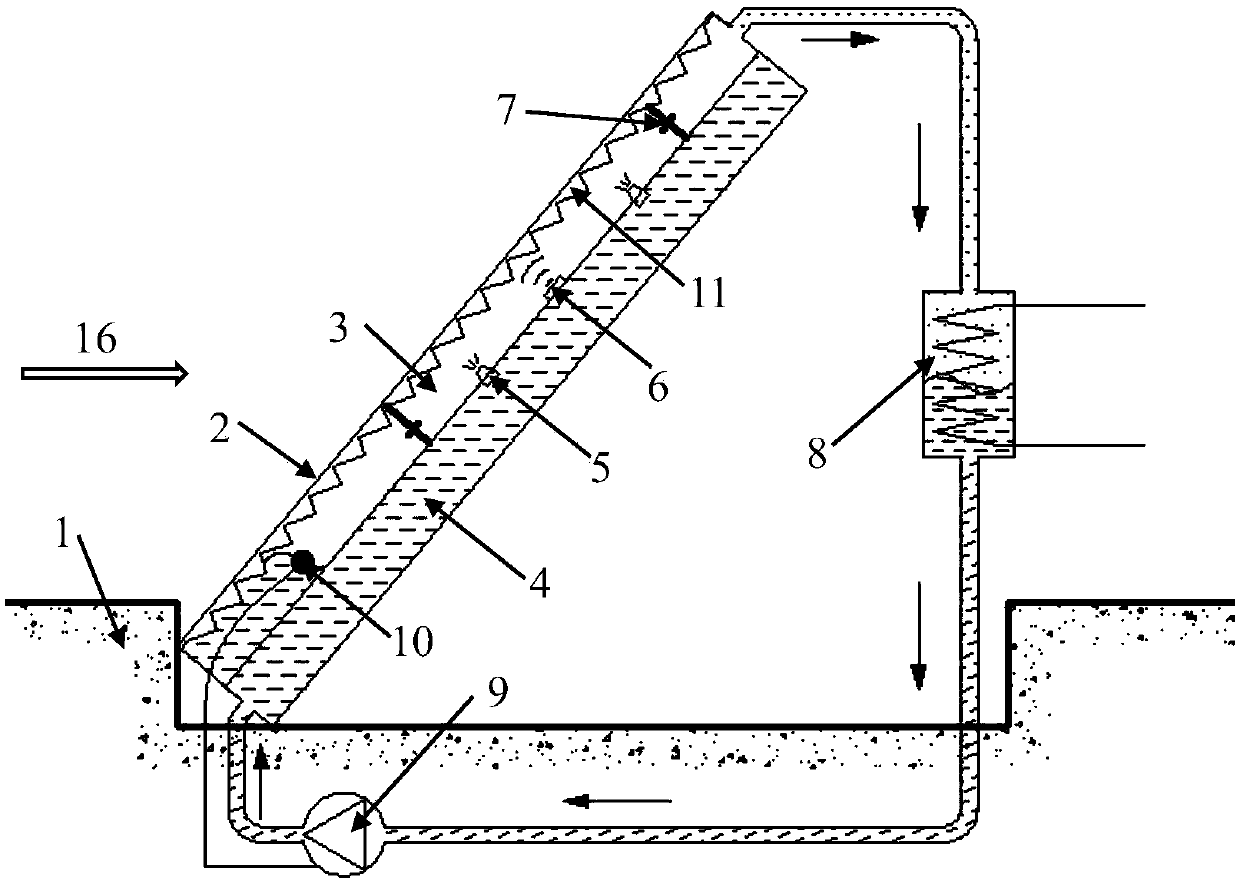

[0030] image 3 A schematic diagram of the gas deflector device for efficiently dissipating heat by using phase change is given, which is mainly composed of two parts: the deflector and the external circulation heat exchange system. When the deflector plate body 2 does not need to work, it is directly embedded in the deck 1, which can save space. The deflector includes a deflector plate body 2 , a phase change atomization chamber 3 and a liquid chamber 4 , and the inner surface of the deflector plate body 2 is a serrated base 11 . The external circulation heat exchange system includes a heat exchanger 8 , a pump 9 and a plate liquid level control device 10 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com