A kind of mud pulse generator oil filling device and using method

A pulse generator and mud pulse technology, applied in the field of wireless inclinometer while drilling, can solve the problems of inability to transmit signals, long oil filling time, pulse damage, etc., to save drilling and maintenance costs, prolong maintenance period, and oil filling Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

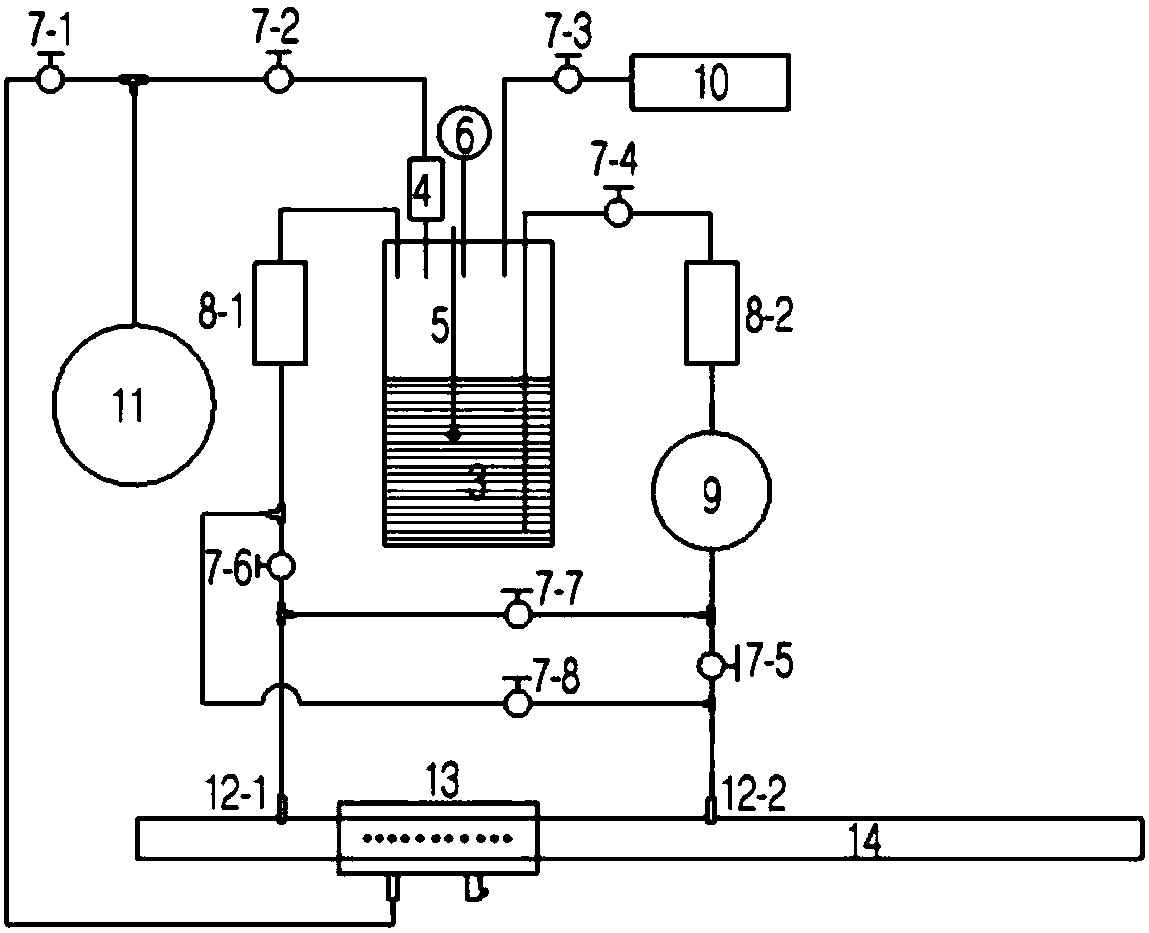

[0018] Embodiment 1, see attached figure 1 , a mud pulse generator oil filling device, which includes: a vacuum oil cup 3, a breather filter 4, a circulation pump 9, an oil storage tank 10, a vacuum pump 11 and a negative pressure assembly 13, and the peripheral equipment is a pulse generator 14;

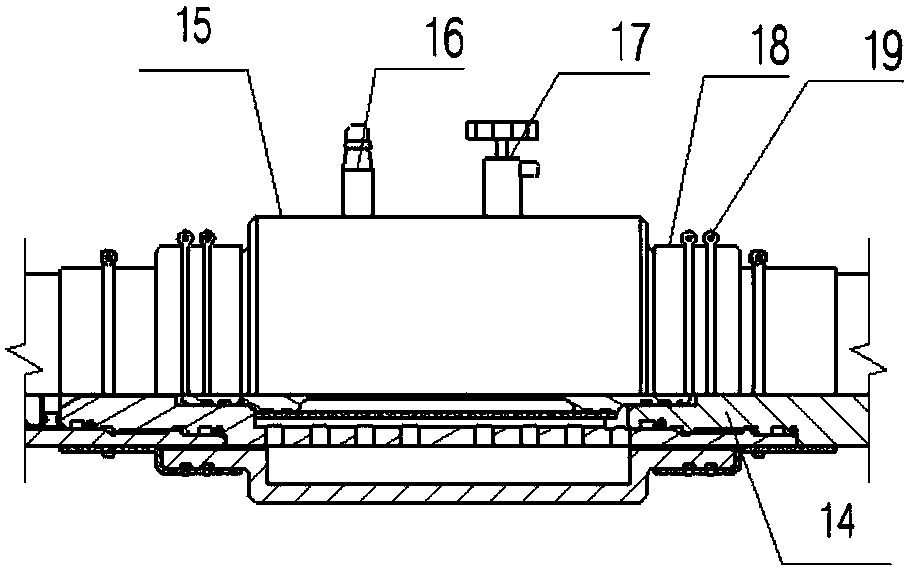

[0019] See attached figure 2 , the negative pressure assembly 13 includes: a housing 15 provided with a quick joint 16 and a slow air release valve 17; the housing 15 is installed outside the compensating membrane of the pulse generator 14 through a rubber sleeve 18 and a clamp 19;

[0020] The overall connection relationship of the oil filling device is: on the one hand, the vacuum pump 11 is connected to the quick connector 16 of the negative pressure assembly 13 through the first solenoid valve 7-1, and on the other hand, it is connected to the second solenoid valve 7-2 and the ventilation filter 4 in turn. To the vacuum oil cup 3; the vacuum oil cup 3 is provided with a pressu...

Embodiment 2

[0023] Embodiment 2, the use method of the mud pulse generator oil filling device, it uses the mud pulse generator oil filling device as described in embodiment 1;

[0024] In the initial state, all solenoid valves are closed;

[0025] The liquid level sensor 5 monitors the oil position inside the vacuum oil cup 3. When the oil in the vacuum oil cup 3 is lower than the set value, the liquid level sensor 5 feeds back a signal to the circuit control assembly, and the circuit control assembly controls the second electromagnetic The valve 7-2 and the vacuum pump 11 are opened, and the vacuum pump 11 vacuumizes the vacuum oil cup 3; when the pressure gauge 6 detects that the pressure in the vacuum oil cup 3 reaches the requirement, the circuit control assembly closes the vacuum pump 11 and the second solenoid valve 7 -2, open the third solenoid valve 7-3 at the same time, supply oil to the vacuum oil cup 3 through the oil storage tank 10, when the oil inside the vacuum oil cup 3 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com