Coning-grinding integrated drill for ground stress test

An integrated, in-situ stress technology, applied to drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of drill bit time waste, cumbersome operation, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

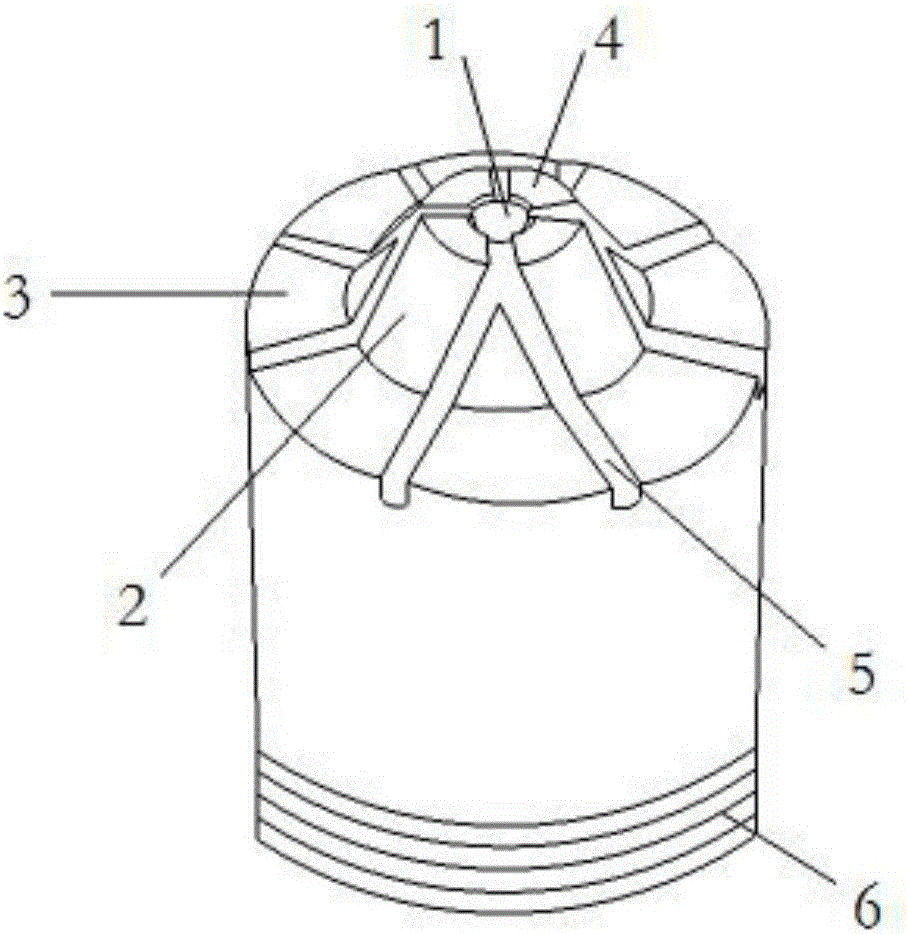

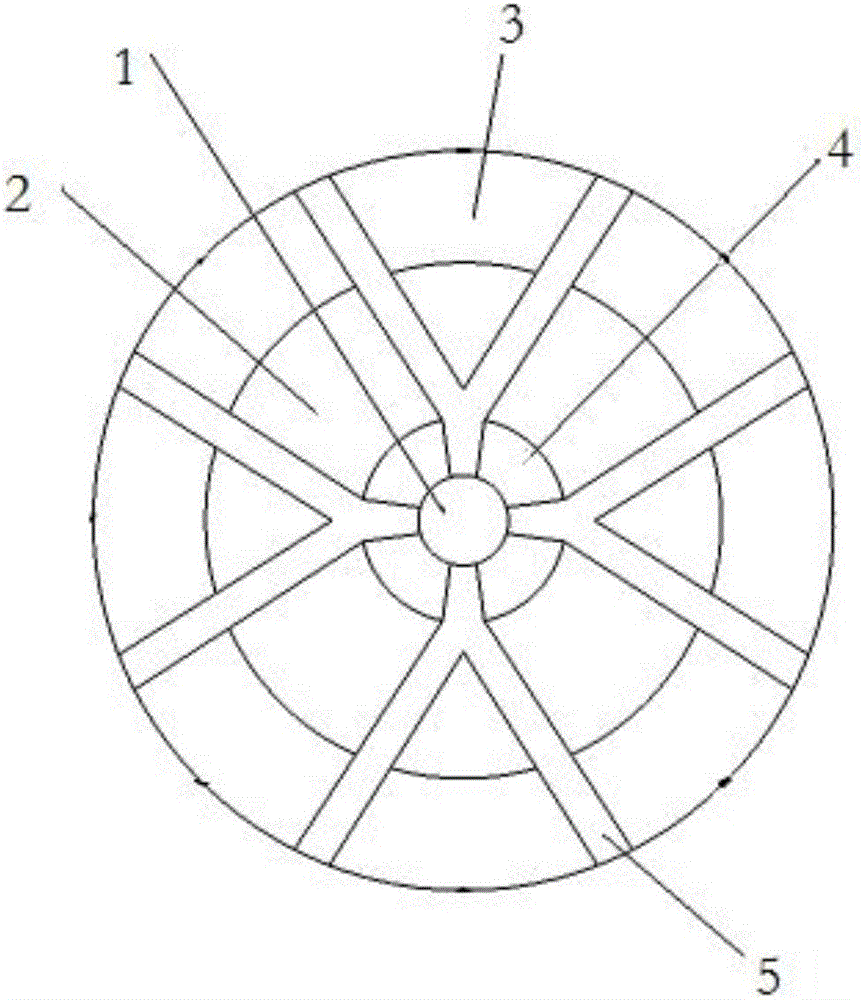

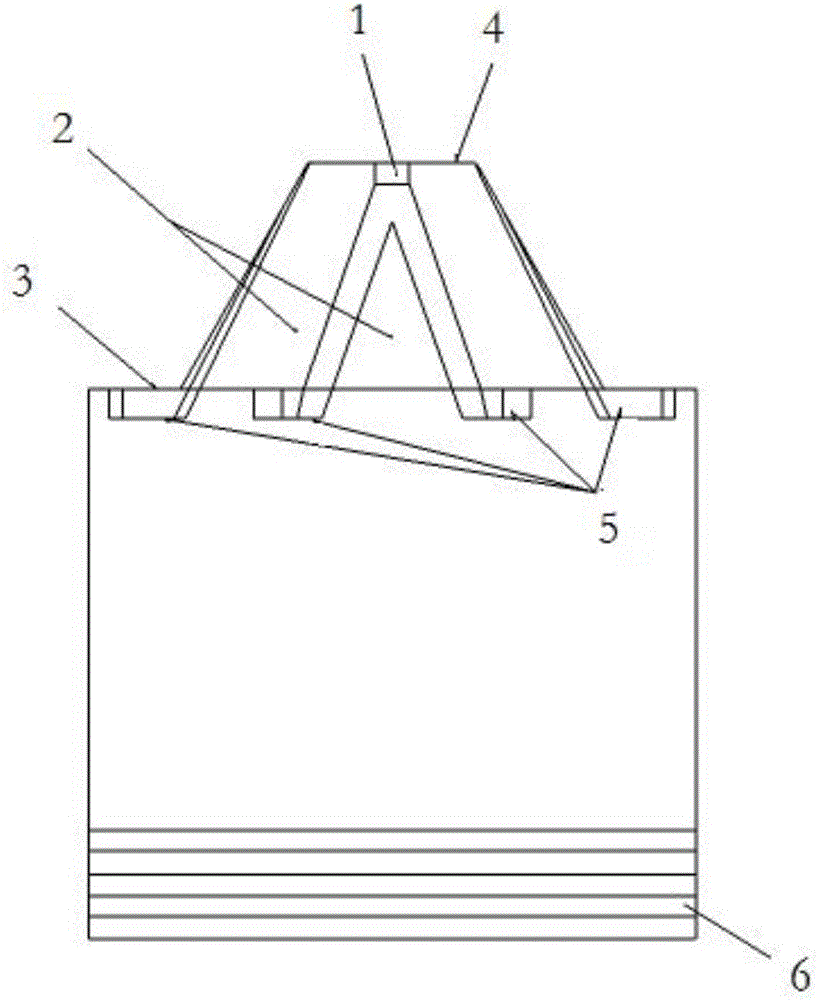

[0027] Such as Figure 1~3 As shown, a cone-mill integrated drill bit for ground stress testing includes a water return port 1, the outer side of the water return port 1 is a conical plane 4, the outer edge of the conical plane 4 is connected to the conical surface 2, and the other end of the conical surface 2 is connected to the conical surface 2. The grinding plane 3 is connected, the grinding plane 3 is parallel to the cone plane 4, and the drainage channel 5 communicates with the water return port 1 through the grinding plane 3, the cone surface 2 and the cone plane 4. There are four drainage channels 5 in the shape of a "herringbone" in total, and their bifurcation points are located at the junction of the conical plane 4 and the conical surface 2 . The tapered surface 2, the grinding surface 3 and the tapered surface 4 are all made of electroplated diamond, and the angle between the tapered surface 2 and the horizontal plane is 60 degrees. Threaded buttons 6 are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com