Multi-unit connecting rod driving plane high-load sliding type controllable wood forking machine

A connecting rod-driven, multi-unit technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. capacity, low mechanical energy consumption and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

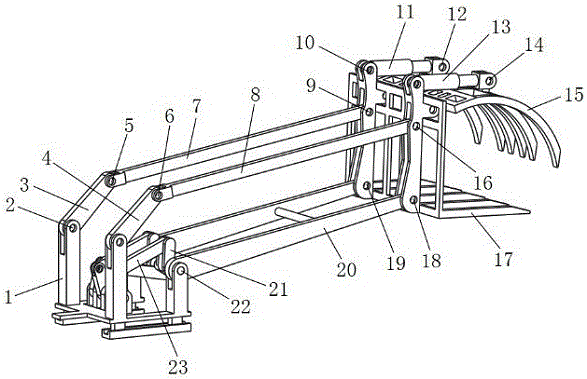

[0026] control figure 1 , a multi-unit connecting rod drive planar high-load sliding controllable forklift according to the present invention includes a multi-unit connecting rod driving mechanism, a boom 20 , a bucket control mechanism and a frame 1 .

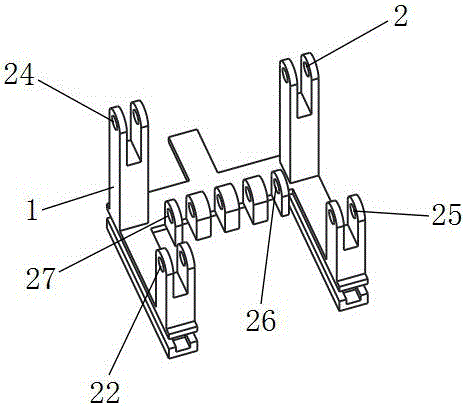

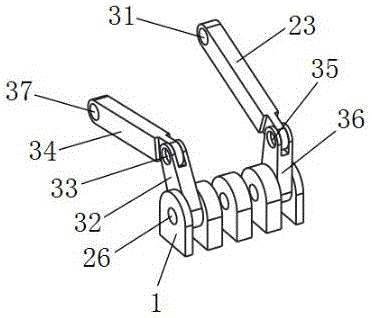

[0027] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the multi-unit connecting rod drive mechanism includes a first active rod 36, a second active rod 32, a first connecting rod 23, a second connecting rod 34, and a crankshaft 21, and one end of the first active rod 36 passes through the first rotating pair 27 is connected with the frame 1, and the other end is connected with one end of the first connecting rod 23 through the second rotating pair 35, and the other end of the first connecting rod 23 is connected with the crankshaft 21 through the third rotating pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com