A method for making and installing cast-in-place box girder formwork

An installation method and formwork technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as complex construction process, poor surface quality, and short service life, and achieve high construction quality, light weight, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

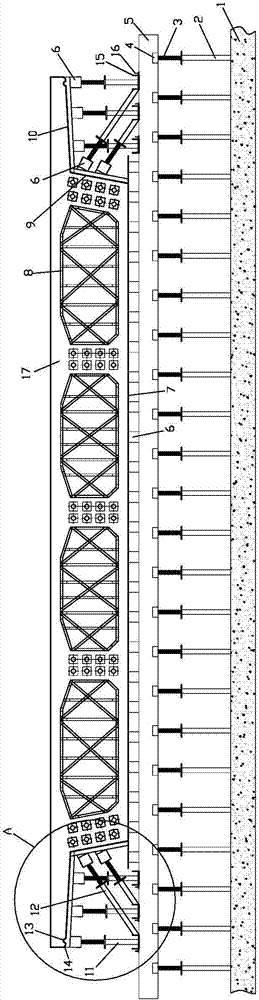

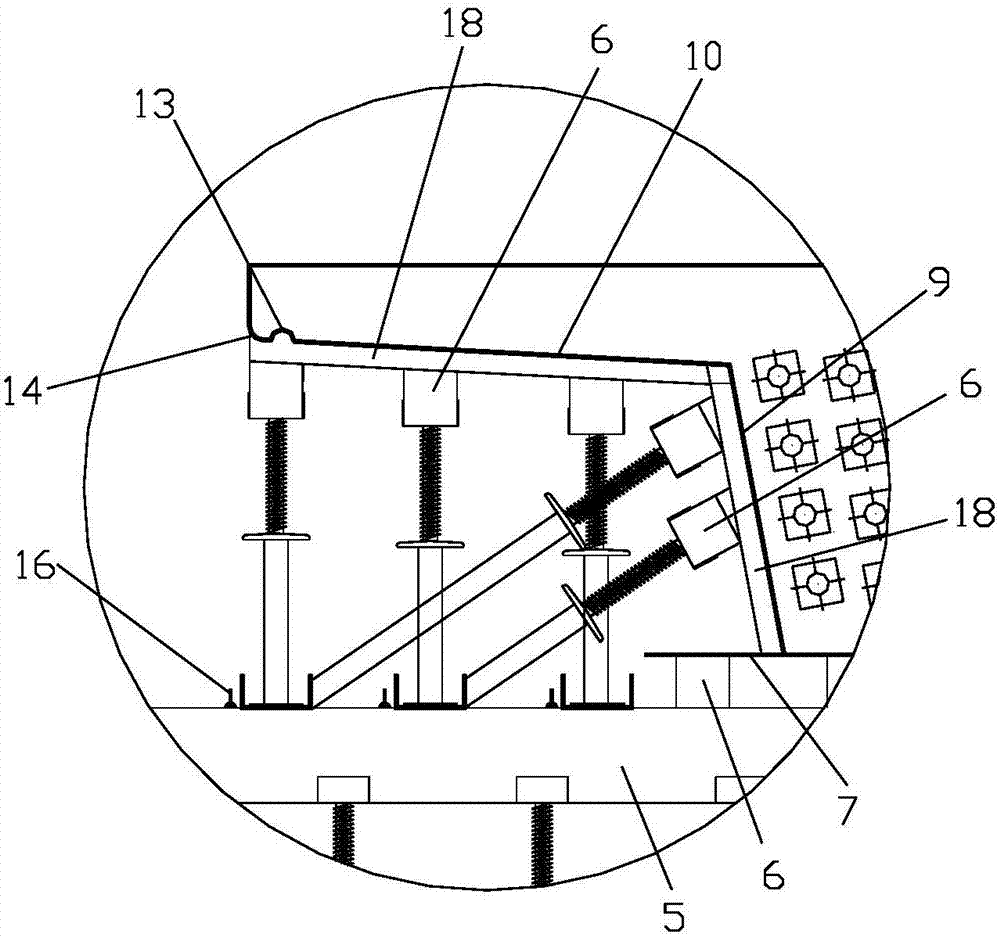

[0034] Such as figure 1 As shown, a method for making and installing a cast-in-place box girder formwork according to the present invention comprises the following steps:

[0035] 1) Manufacture of cast-in-place box girder formwork;

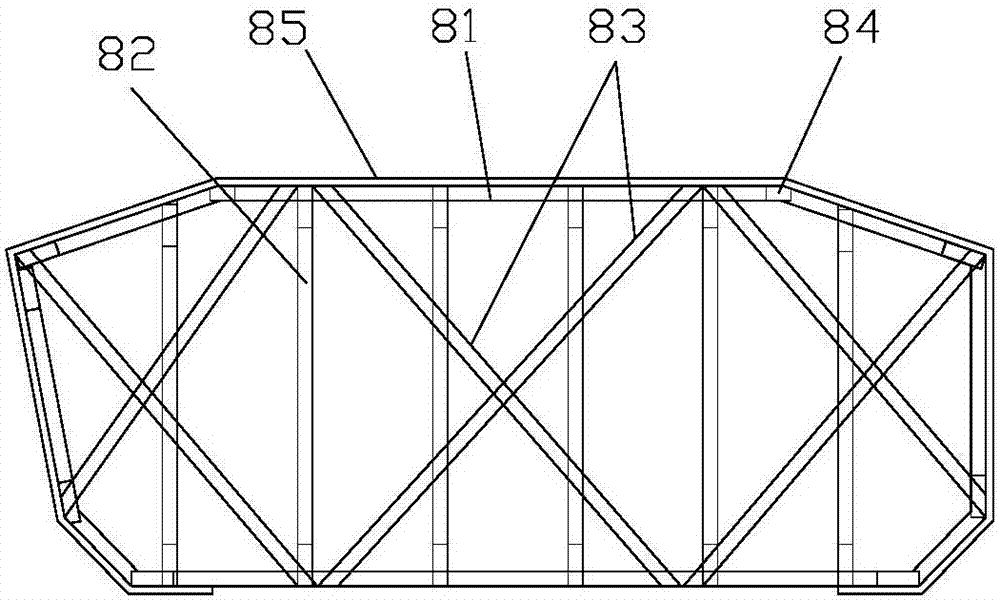

[0036] a. The cast-in-place box girder formwork includes the bottom formwork 7 placed at the bottom of the bridge body 17, the box chamber formwork 8 placed inside the bridge body 17, the side formwork 9 placed on both sides of the bridge body 17 and placed on both sides of the bridge body 17 The flange plate formwork 10 at the bottom of the extended end; the cast-in-place box girder formwork is all made of clear water formwork. In order to reduce the formwork joints, the largest specification clear water formwork of 2440m×1220mm is preferred when the size is suitable;

[0037] b. The bottom formwork 7 and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com