A self-propelled concrete chisel machine and its chisel method

A technology of concrete and chiseling machine, which is applied in the direction of roads, road repairs, roads, etc. It can solve the problems of increasing the complexity of personnel manipulation, and there is no satisfactory automatic chiseling device, so as to achieve high chiseling efficiency and improve the chiseling efficiency. Gross efficiency, the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with specific examples.

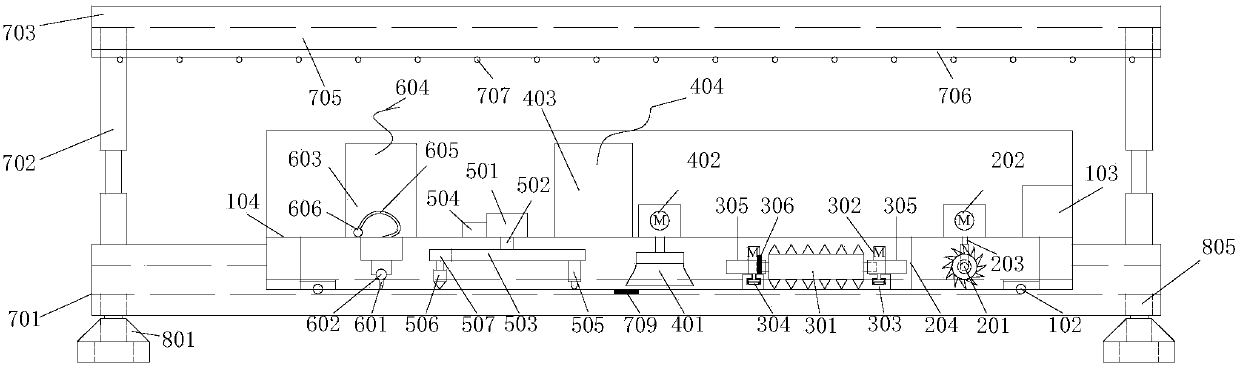

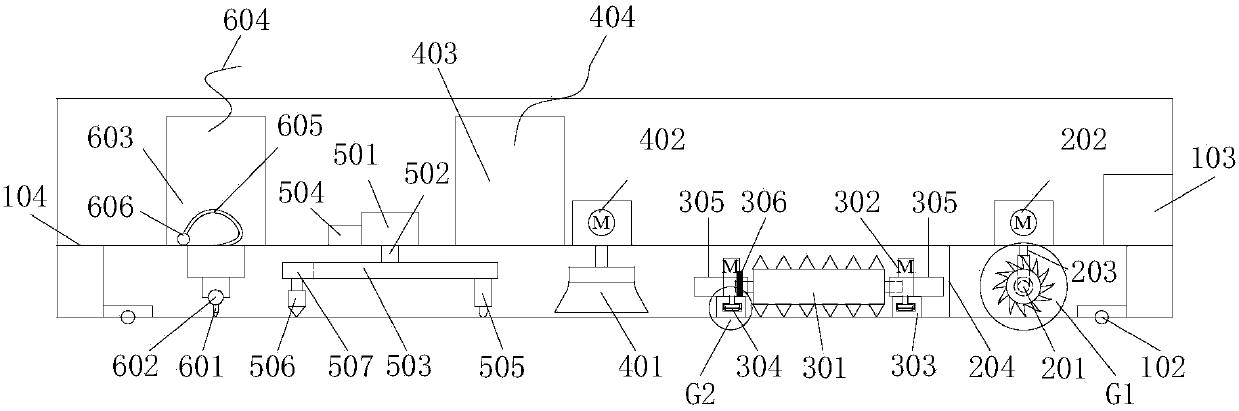

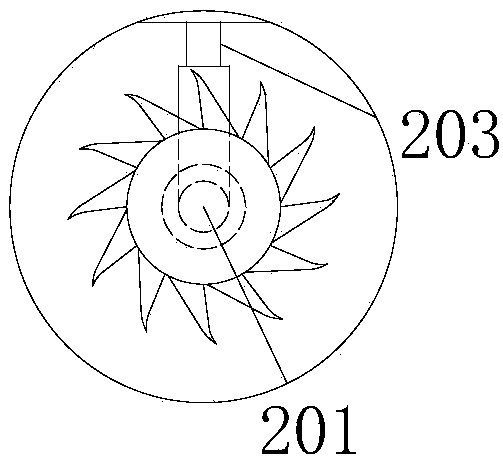

[0067] Such as Figure 1 to Figure 11 Shown, a kind of self-propelled concrete chiseling machine comprises chisel trolley, trolley track system; Wherein chisel trolley comprises: trolley walking system, longitudinal alveolar chisel system, transverse alveolar chisel system, sweep suction system, wool Surface adjustment system, sprinkler system.

[0068] The trolley walking system is the core for chiseling, and it includes: a trolley frame 101, a trolley roller 102, a trolley walking drive 103 and a dividing plate 104.

[0069] The upper and lower sides of the trolley frame 101 are provided with trolley rollers 102, and the trolley frame 101 is "embedded" in the track beam 701 of the trolley track system to prevent the chiseling trolley from detaching from the track beam 701, thereby ensuring that the chiseling trolley is applicable Concrete gouging on multi-angle planes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com