A kind of preparation method of unsaturated polyester furniture coating

A furniture coating, unsaturated technology, applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problems of low hardness, poor air drying, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

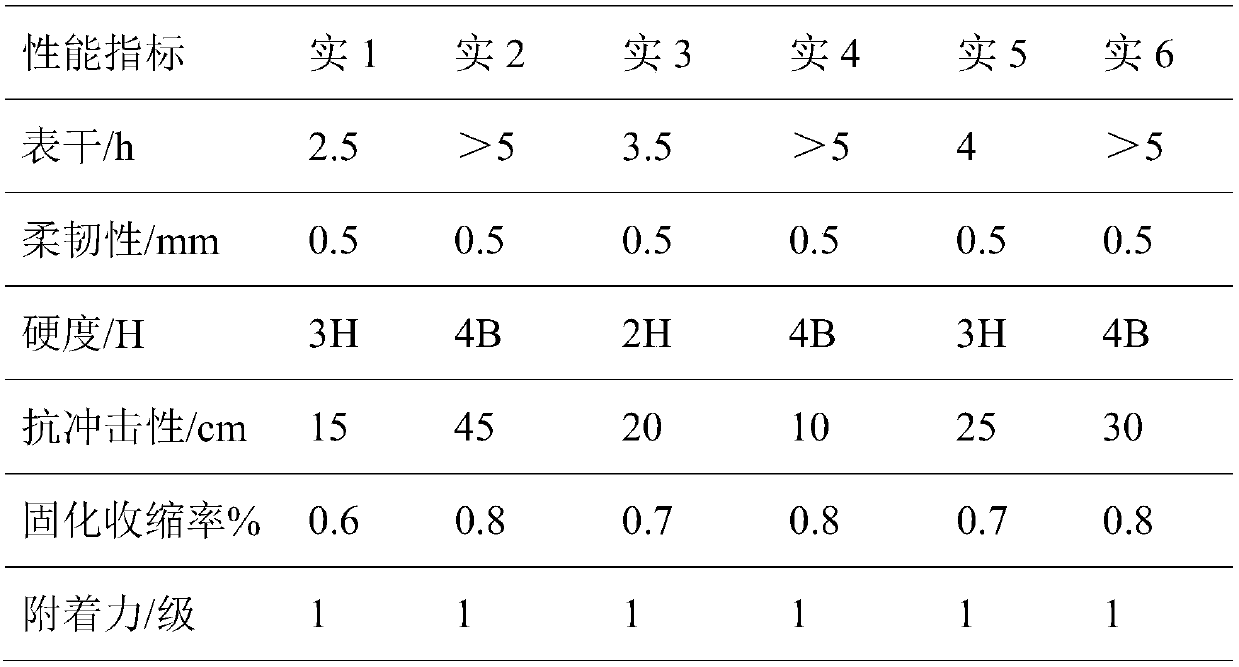

Examples

preparation example Construction

[0030] A kind of preparation method of unsaturated polyester furniture coating of the present invention comprises the following concrete steps:

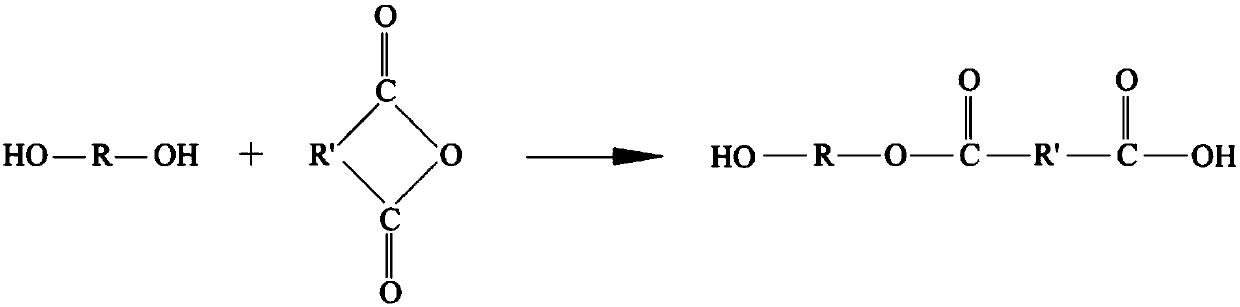

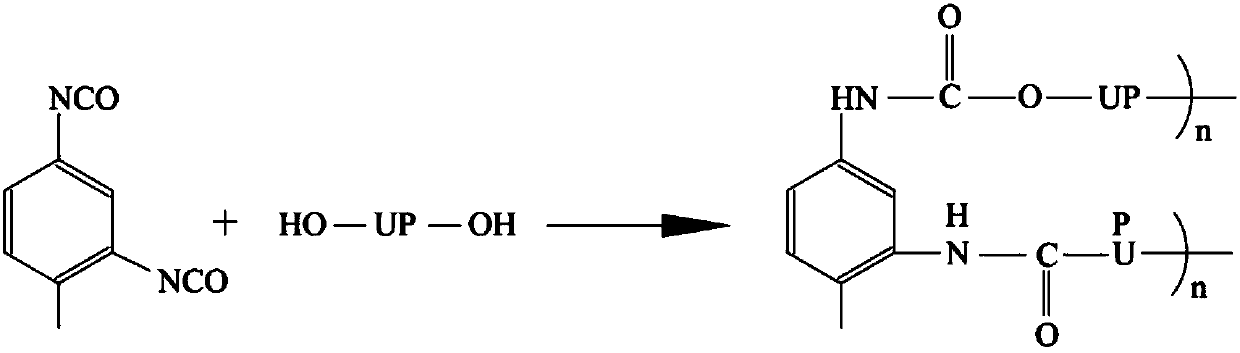

[0031] (1) Preparation of unsaturated polyurethane (UP)

[0032] a. Heat a certain amount of saturated and unsaturated dicarboxylic acids or anhydrides, a small amount of rosin, a catalyst, and an oil bath until the reaction materials are completely dissolved, then start stirring, and raise the temperature to 210-260°C, keep it warm for 20-45min, until the acid value Reduced to 5mgKOH / g-10mgKOH / g, modified rosin;

[0033] b. Then lower the temperature to 140-180°C, and start to add 40%-60% of the total amount of diol dropwise. After the dropwise addition, raise the temperature to 170-190°C to continue the reaction, and take a sample every 1h to measure the acid value. When the change range of the acid value decreases, lower the temperature to 160°C and add the remaining glycol at one time, and then continue to heat up to 190-210°C f...

Embodiment 1

[0043] A kind of preparation of unsaturated polyester furniture coating, prepares according to following steps:

[0044] (1) Heat saturated and unsaturated dibasic carboxylic acids or dibasic acid anhydrides, a small amount of rosin, a catalyst, and an oil bath until the reaction raw materials are completely dissolved, then start stirring, and raise the temperature to 230°C, keep the temperature for 30min, then cool down to 180°C, press Proportionally add 40% glycol, start stirring, heat up to 190°C and continue to react until the acid value change range decreases, then cool down to 160°C and add the remaining glycol at one time, then continue to heat up to 190°C for 3 hours, Then lower the temperature to 100°C, add the polymerization inhibitor hydroquinone and stir thoroughly, then cool down to 80°C and then add styrene to adjust the viscosity, that is, the UP oligomer with terminal hydroxyl group (rosin modified HO—UP—OH oligomer substance solution);

[0045] The ratio of e...

Embodiment 2

[0049] A kind of preparation of unsaturated polyester furniture coating, prepares according to following steps:

[0050](1) Heat saturated and unsaturated dibasic carboxylic acids or dibasic acid anhydrides, a small amount of rosin, a catalyst, and an oil bath until the reaction raw materials are completely dissolved, then start stirring, and raise the temperature to 210°C, keep the temperature for 45min, then cool down to 160°C, press Proportionally add 50% diol, start stirring, heat up to 170°C and continue to react until the acid value change range decreases, then cool down to 160°C and add the remaining diol at one time, then continue to heat up to 200°C for 2 hours, Then lower the temperature to 100°C, add the polymerization inhibitor hydroquinone and stir thoroughly, then cool down to 80°C and then add styrene to adjust the viscosity, that is, the UP oligomer with terminal hydroxyl group (rosin modified HO—UP—OH oligomer substance solution);

[0051] The ratio of each r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com