Operating method of wastewater treatment system

A treatment system and working method technology, applied in the direction of processing wastewater treatment, multi-stage water treatment, water treatment parameter control, etc., can solve the problems of fiber recovery, waste water reuse restrictions, a large number of chemical agents, etc., to achieve equipment Low requirements, mild treatment process, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

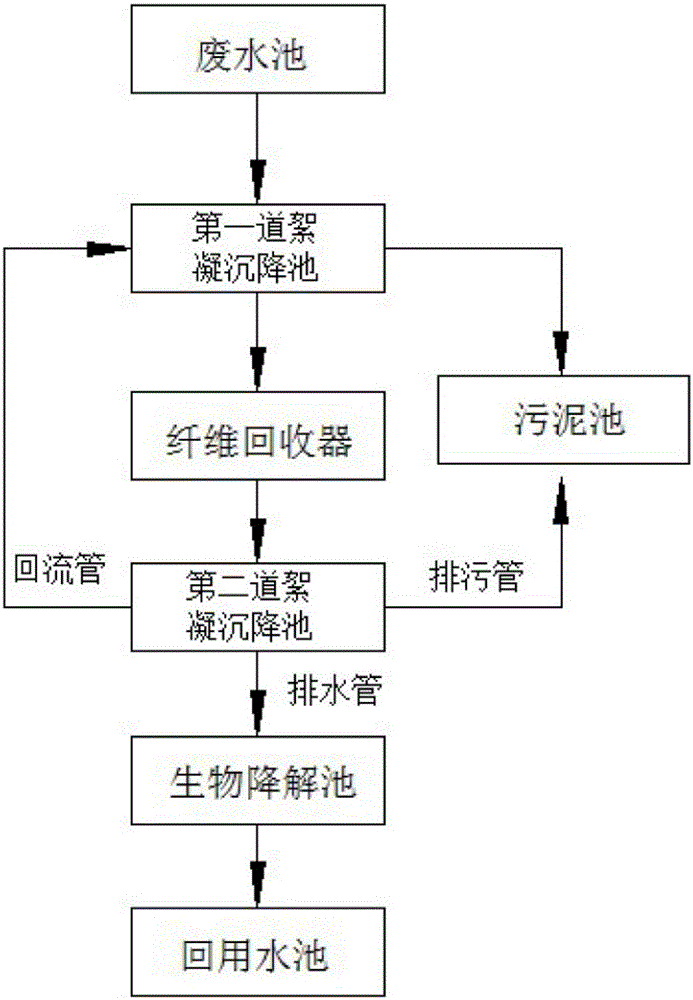

[0035] figure 1 It is a schematic diagram of the equipment connection relationship of the present invention. It can be seen from the accompanying drawings that the present invention includes a waste water tank, a first flocculation settlement tank, a fiber recovery device, a second flocculation settlement tank, a biodegradation tank, a sludge tank and a reuse water tank. The waste water pool is connected to the waste water discharge pipeline from the papermaking workshop, the waste water in the waste water pool is transported to the water inlet end of the first flocculation settling tank through the waste water pipeline, and the water discharge end of the first flocculation settling tank passes through the pipeline Connect to the water inlet end of the fiber recovery device, the water discharge end of the fiber recovery device is connected to the water inlet end of the second flocculation settlement tank, and the water discharge end of the second flocculation settlement tank is...

Embodiment 2

[0040] There are more than two first flocculation-settling tanks, and more than two first flocculation-settling tanks are connected in series, and the water discharge end of the first flocculation-settling tank is connected to the inlet of the adjacent first flocculation-settling tank. At the water end, all the first flocculation and settling tanks share a sludge tank.

[0041]The connection relationship of the waste water tank, the fiber recoverer, the second flocculation and sedimentation tank, the biodegradation tank, the sludge tank and the reused water tank is the same as that of Embodiment 1.

Embodiment 3

[0043] The second flocculation-settling tank has more than two, and more than two second flocculation-settling tanks are connected in series, and the water discharge end of the second flocculation-settling tank is connected to the inlet of the adjacent second flocculation-settling tank. At the water end, the upper, middle and bottom layers of all the second flocculation-settling tanks are respectively provided with drainage pipes connected to the biodegradation tank, return pipes connected to the first flocculation-settling tank and sewage pipes connected to the sludge tank, All the second flocculation settling tanks share one sludge tank.

[0044] The connection relationship of the waste water tank, the fiber recoverer, the first flocculation and sedimentation tank, the biodegradation tank, the sludge tank and the reused water tank is consistent with that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com