Wing connecting device, wing and aircraft

A connecting device and wing technology, which is applied in the direction of wings, aircraft parts, transportation and packaging, etc., can solve the problems of low safety of wing connecting device, damage of wing connecting device, wing falling off, etc., so as to reduce assembly errors Rate and scrap rate, reduced calibration steps, improved safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

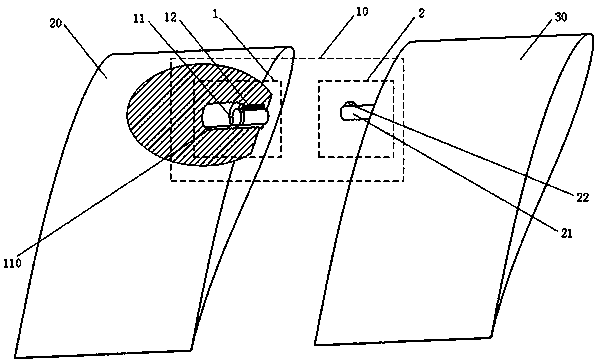

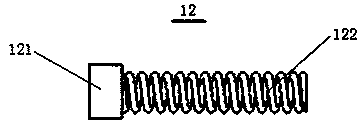

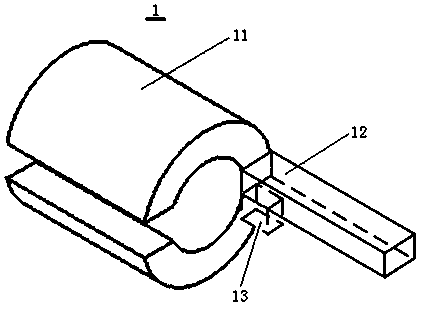

[0038] This embodiment provides a wing connection device, which can be applied to the assembly of aircraft wings, such as the assembly of the inner and outer wings of a fixed-wing unmanned aerial vehicle, such as figure 1 As shown, the wing connection device 10 includes: a first joint unit 1 and a second joint unit 2 . The first joining unit 1 is embedded in the first wing part 20 , and the first wing part 20 may be, for example, an inner wing or an outer wing. The first joining unit 1 includes a hollow rotating column 11 and a telescopic block 12 . Rotary column 11 is used for rotating around its axis, as figure 1 As shown, the rotating column 11 is in the shape of a hollow cylinder, and the rotating column 11 may also be a hollow cone, a truncated cone, a cuboid, etc. according to actual needs. The cylindrical rotating column 11 has side surfaces and two bottom surfaces, and the rotating column 11 can rotate around its central axis. A groove 110 parallel to the axis of th...

Embodiment 2

[0045] This embodiment provides a wing connecting device, such as Figure 4 As shown, in addition to the features of the wing connection device in Embodiment 1, it also includes: a first positioning hole 3 and a first positioning pin 4 . The first positioning hole 3 is embedded in the first wing portion 20 . The first positioning pin 4 is circumscribed on the second wing portion 30 , and is used for cooperating with the first positioning hole 3 to be inserted into the first positioning hole 3 .

[0046] The effect of the first positioning hole 3 and the first positioning pin 4 is mainly to assist positioning when the first and second wing parts are docked, and further ensure that the outer surfaces of the first wing part 20 and the second wing part 30 are in the same shape. Cooperate. Moreover, the cooperation between the first positioning hole 3 and the first positioning pin 4 can also prevent the relative rotation of the first and second wing parts during flight, thereby i...

Embodiment 3

[0054] This embodiment provides a wing, including: a first wing part 20 , a second wing part 30 , and the wing connection device 10 of the above-mentioned embodiment 1 or 2. The first wing part 20 is connected to the second wing part 30 through the wing connecting device 10 . The wing has the advantages of high safety and high durability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com