Preparation method of wind turbine blade web of wind power generating set

A technology for wind turbines and wind rotor blades, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., and can solve problems such as difficult to guarantee curing, difficult to guarantee the accuracy of bonding position and bonding angle, etc. , to achieve the effect of good scraping, strong practicability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

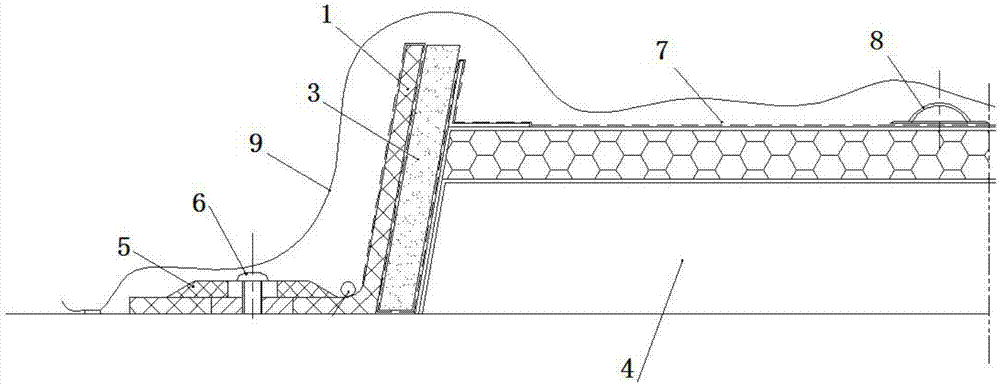

[0024] Such as figure 1 Shown, a kind of preparation method of wind turbine blade web, it comprises the following steps:

[0025] a. First open a U-shaped hole in the glass fiber reinforced plastic movable rib (1);

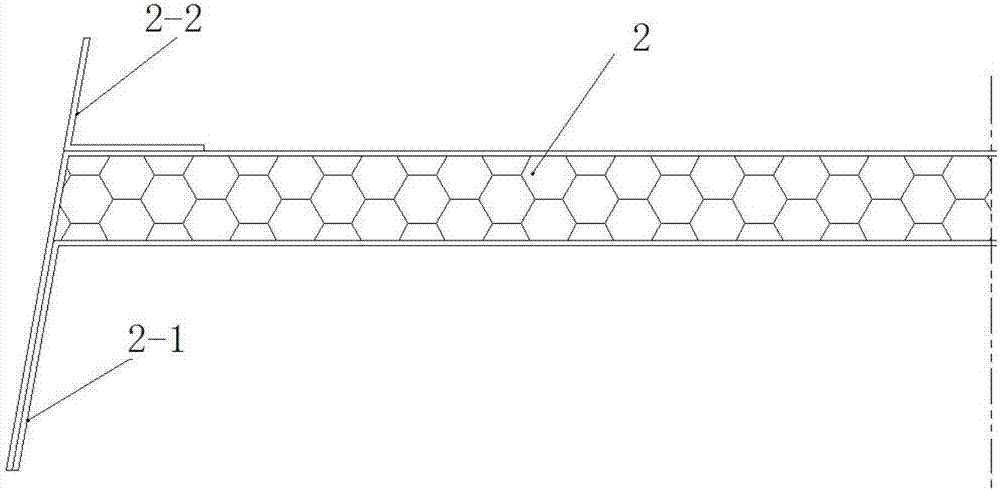

[0026] b. According to the laying sequence of the web (2), lay the inner skin cloth, core material and outer skin cloth of the web, and lay the release cloth on the main adhesive corner area of the web at the same time. When the release cloth is laid in this area, the web The main bonding surface and auxiliary bonding surface must be completely covered with release cloth; so as to ensure that the roughness of the main bonding surface and auxiliary bonding surface meets the requirements;

[0027] c. Place a silica gel plate (3) in the main adhesive area of the web (2), and overlap the glass fiber reinforced plastic movable rib (1) with the main mold of the web (4) by 100mm;

[0028] d. Install the positioning block (5) according to the opening on the glass fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com