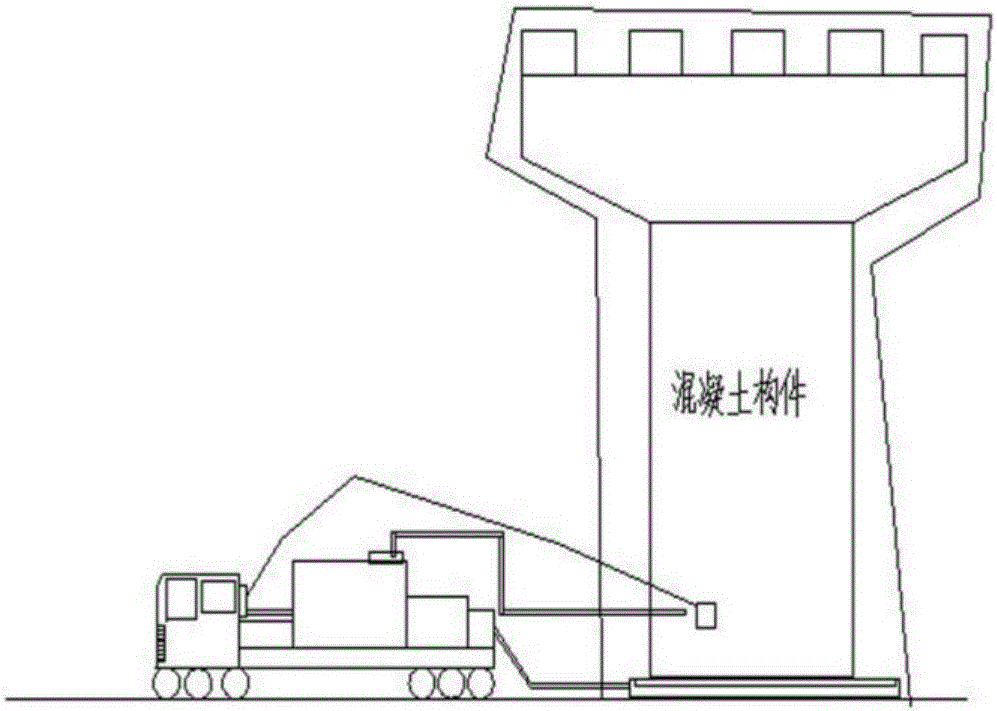

Movable type device for constant temperature and humidity standard maintenance of concrete member

A constant temperature and humidity, standard maintenance technology, applied in non-electric variable control, instrument, control of multiple variables at the same time, etc., can solve the problems of complex installation and disassembly, large resource consumption, can not be naturally decomposed, etc., to achieve easy installation and disassembly. The effect of reducing the waste of water resources and reducing the consumption of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

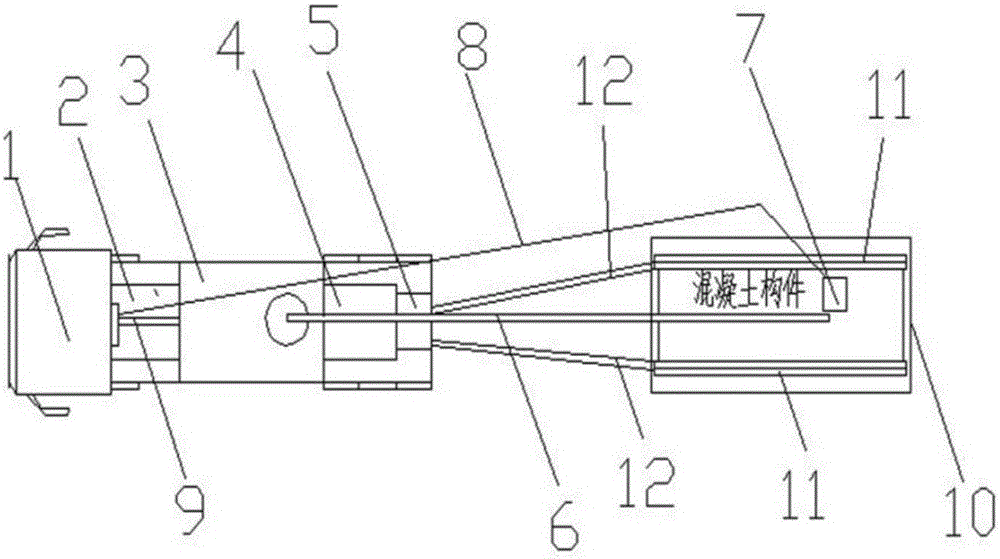

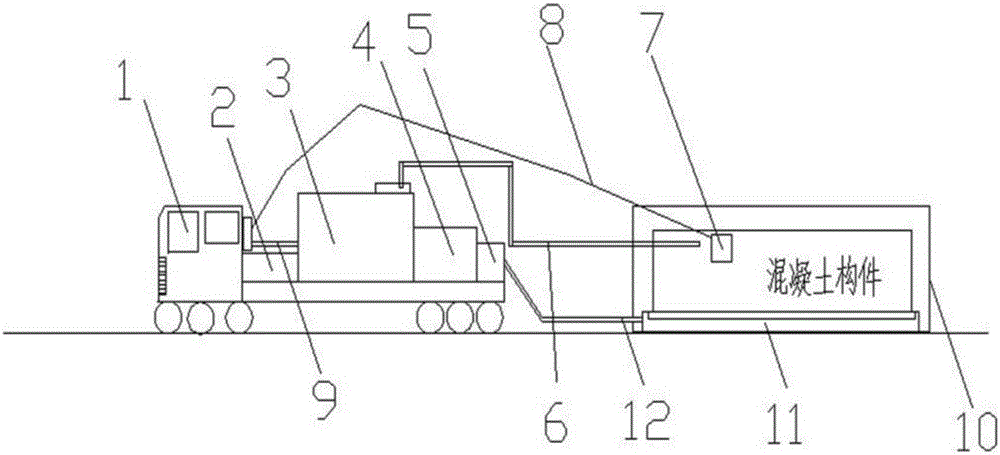

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] As shown in the figure, the device for standardized maintenance of mobile constant temperature and constant humidity concrete components of the present invention includes: test vehicle 1, power supply equipment 2, standard maintenance gas generation equipment 3, water storage tank 4, maintenance residual water recovery equipment 5, marking Conservation gas delivery pipeline 6, temperature and humidity measurement sensor 7, connection cable between temperature and humidity measurement sensor and test vehicle 8, connection cable between test vehicle and marked maintenance gas generation equipment 9, heat preservation and moisturizing sealing sleeve 10, recovery water cut-off tank 11, recovery water delivery pipe 12;

[0019] The assembly relationship is as follows: the temperature and humidity control equipment is installed in the front of the test vehicle 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com