Automatic assembling machine tool of automobile starter drive

An automatic assembly and starter technology, applied in the direction of assembly machines, vehicle parts, transportation and packaging, etc., can solve the problems of inability to meet market production capacity requirements, reduce product reliability, and complex assembly processes, and reduce labor intensity and parts. Assembly difficulty, improve assembly quality, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

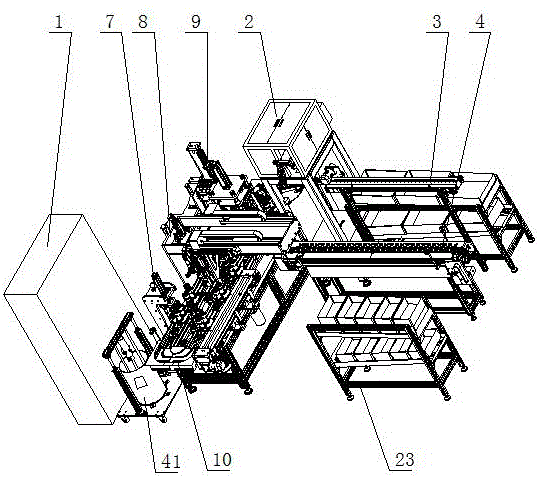

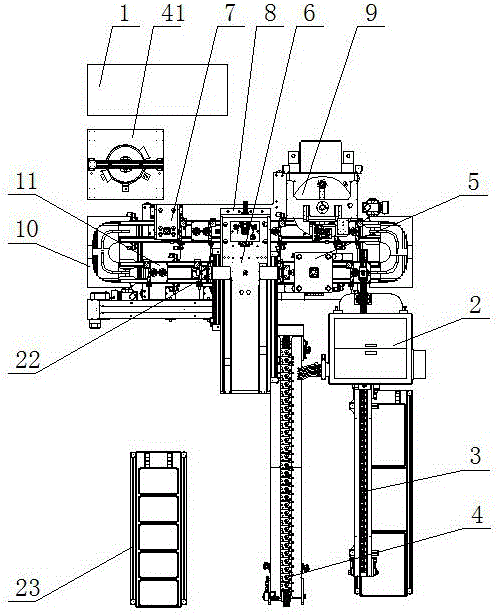

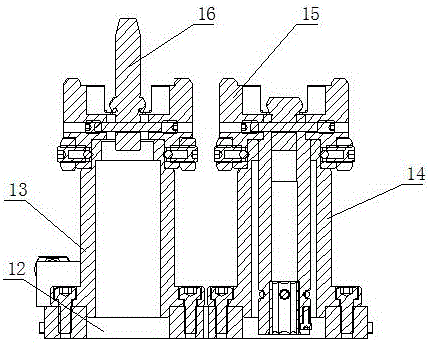

[0023] The automobile starter one-way automatic assembly machine tool includes an electrical control cabinet 1, a vibrating feeding device 2, a guide cylinder transmission line 3, a drive gear transmission line 4, a transposition device 5, a spinning device 6, a grease injection device 7, a roller press Mounting device 8, spring pressing device 9 and circulation transmission line 10. The front end of the circular transmission line 10 is provided with a drive gear transmission line 4, which is used for the transmission of the drive gear workpiece to be assembled; one side of the drive gear transmission line 4 is provided with a guide cylinder transmission line 3, and a vibrator is installed above the end of the guide cylinder transmission line 3 through a support frame. The feeding device 2 and the vibrating feeding device 2 are used for feeding the rollers, and the circular transmission line 10 corresponding to the guide cylinder transmission line 3 is equipped with feeding jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com