Cleaning brush for four-necked flasks for emulsion synthesis

A four-necked flask and emulsion technology, which is applied in the direction of brushes, applications, and bristles, can solve the problems of troublesome cleaning fluid replacement, incomplete cleaning, and dead ends, and achieve the effects of low production cost, simple structure, and simple operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

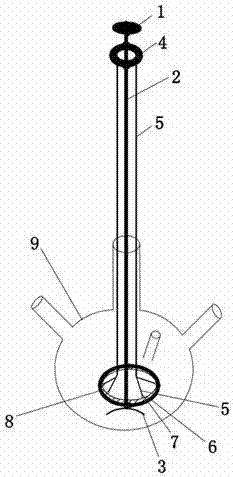

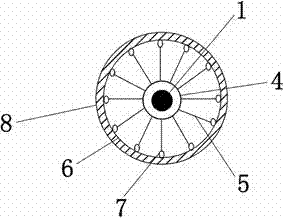

[0019] In this example, see figure 1 with figure 2 A cleaning brush for a four-necked flask for emulsion synthesis, comprising a handle 1, a long and straight brush rod 2 and a brush head part, the brush rod 2 adopts a plastic rod, and the brush head part is installed on the front end of the brush rod 2, The tail of the brush rod 2 forms a handle 1. The brush head part is mainly composed of a suction cup 3 and a thin wire ball 8. The suction cup 3 is made of rubber material. The suction cup 3 is arranged at the front end of the brush rod 2. Conduction through the brush rod 2, so that the suction cup 3 is adsorbed on the inner wall surface corresponding to the bottleneck of the four-necked flask 9, which plays a very good role in stabilizing the flask. The thin wire ball 8 is set on the brush rod 2, and the fine The wire ball 8 can be deformed, and is provided with a deformation brush head expansion and contraction mechanism. The deformation brush head expansion and contracti...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, especially in that:

[0024] In the present embodiment, the front ends of each iron wire 5 are respectively articulated through independent small iron rings 7 and spring coils 6, which is convenient to manufacture and reduces the stress concentration and torque increase caused by the interaction between the small iron rings 7 and spring coils 6. When damage occurs, the connection relationship between the small iron ring 7 and the spring ring 6 is maintained, and the service life of the cleaning brush is improved.

Embodiment 3

[0026] This embodiment is basically the same as the previous embodiment, and the special features are:

[0027] In this embodiment, an auxiliary confinement ring that is enclosed within the brush rod 2 is set inside the thin wire ball 8, the outer ring size of the auxiliary confinement ring is smaller than the inner diameter of the bottle mouth of the four-necked flask 9, and the auxiliary confinement ring is in accordance with the sleeve mouth 4 They are arranged parallel to each other, and all the iron wires 5 pass through the inside of the auxiliary confinement ring. The auxiliary confinement ring makes most of the sections of the iron wire 5 in a straight working state, and only a part of the iron wire 5 in the thin iron ball 8 is in a bent working state, which is conducive to ensuring the maintenance of the stable working state of the iron wire 5 in force transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com