Boom systems for mobile cranes and mobile cranes

A crane and cantilever technology, applied in the field of cantilever systems of mobile cranes, can solve problems such as affecting the maximum length of a telescopic cantilever, and achieve the effects of improving connection rigidity, reducing load, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

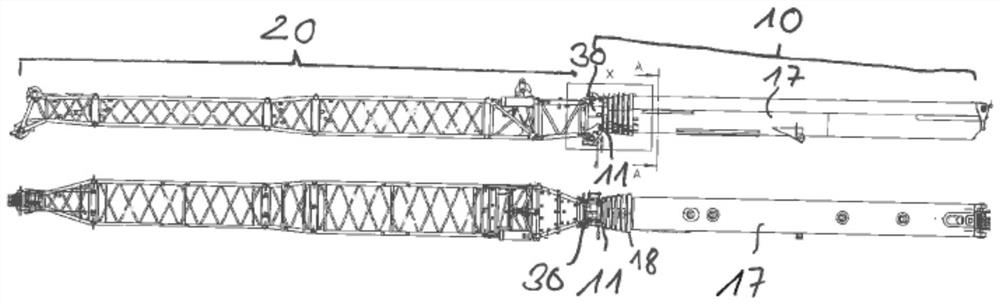

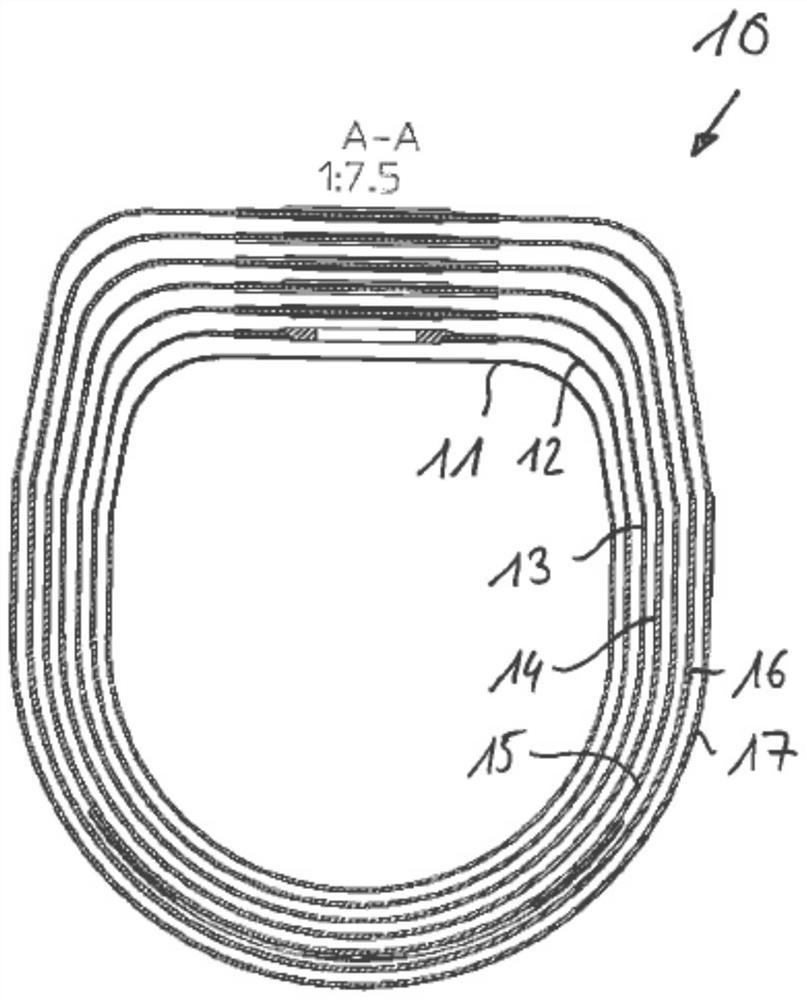

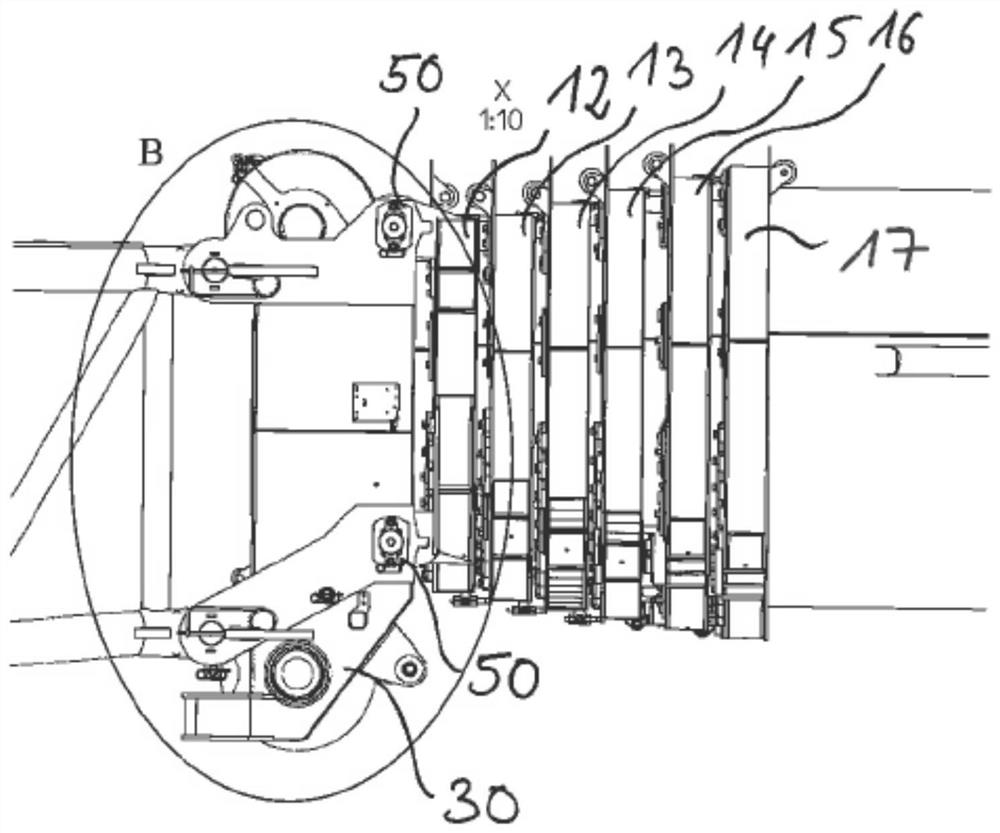

[0036] figure 1The boom system according to the invention is shown in side view and plan view. The cantilever system consists of a telescopic main cantilever 10 and a pointed cantilever in the form of a pivotable truss-like tip 20 fastened thereto by means of bolts. The telescopic jib 10 consists of a total of seven telescopic tube eyelets 11, 12, 13, 14, 15, 16, 17, which are usually mutually supported alternately via support elements. These support elements are fastened from the inside to rims 18 of the telescopic tube eyelets 11 to 17 arranged on the end faces. This telescoping process is carried out by telescoping cylinders, not shown.

[0037] exist image 3 The connection position in the region X between the pointed cantilever 20 and the main cantilever 10 is shown in . It can be seen that the central telescopic tube eye 11 has a roller tip 30 on the end side, to which end the pointed suspension 20 is fastened by means of a four-point screw.

[0038] According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com