Cam clamping mechanism

A cam clamping and cam technology, applied in workpiece clamping devices, circuit board tool positioning, electrical components, etc., can solve the problems of cumbersome control and complex structure of the clamping and positioning mechanism, and achieve low cost, simple and fast mechanism structure The effect of clamping positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

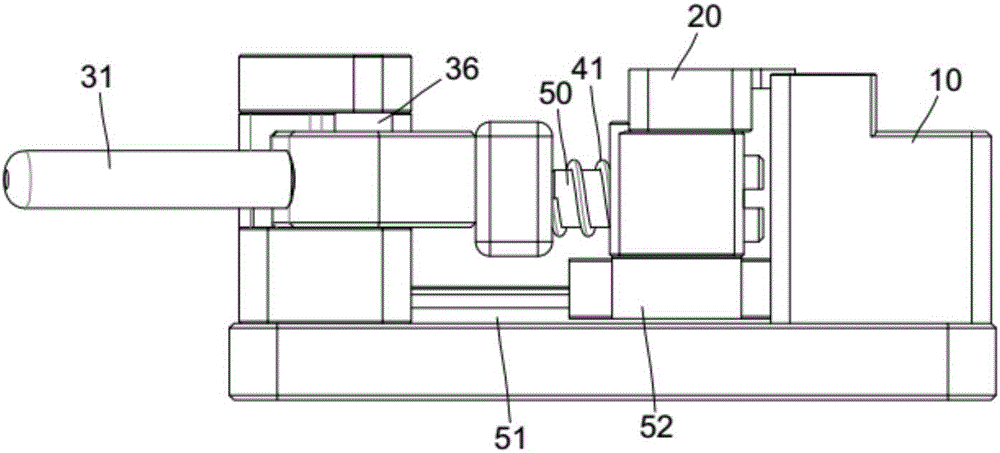

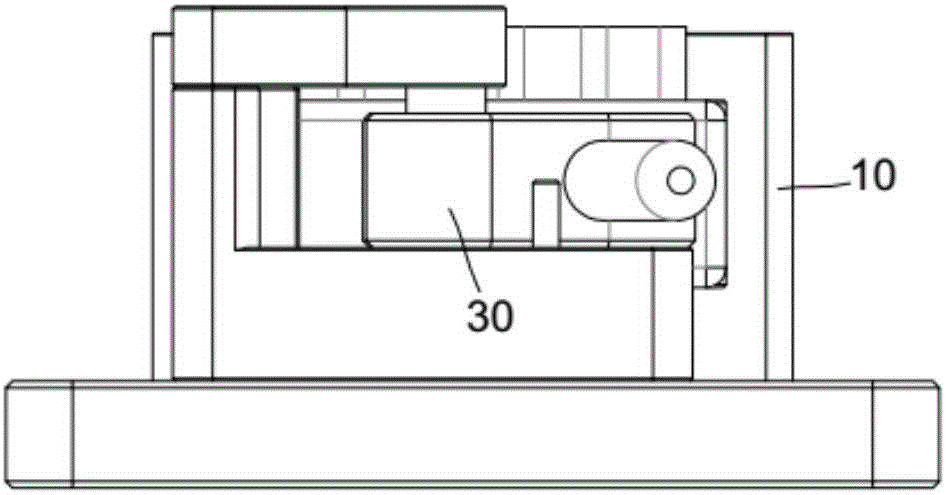

[0026] refer to Figure 4 , a cam clamping mechanism, including a clamping block 20 located on the side of the carrier 10, a guide mechanism for guiding the linear movement of the clamping block, and the clamping block is driven by a cam 30.

[0027] combine figure 2 , Figure 4 , the cam 30 is rotatably mounted on the camshaft 36 . The clamping base plate 60 is fixedly equipped with a cam base 34, and the cam base is fixedly locked with a cam shaft fixed block 35 through a tooth hole, and the cam shaft 36 is installed between the cam shaft fixed block and the cam base. The cam is fixed with a cam lever 31, which is used in conjunction with a stop post 32 on the cam base to block and limit the cam lever.

[0028] combine figure 1 , figure 2 , Figure 4 , the cam 30 drives the clamping block 20 through the elastic assembly. The elastic assembly includes a forward push block 40 in contact with the cam 30 , and a fixed block 42 connected to the forward push block through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com