Female plug, male plug and high-voltage large-current connector

A technology of high-current connectors and connectors, which is applied in the direction of vehicle connectors, devices for connecting/disconnecting connected parts, and connections, which can solve problems such as increasing the time for unplugging connectors, prolonging the man-hours required for maintenance, and troublesome disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

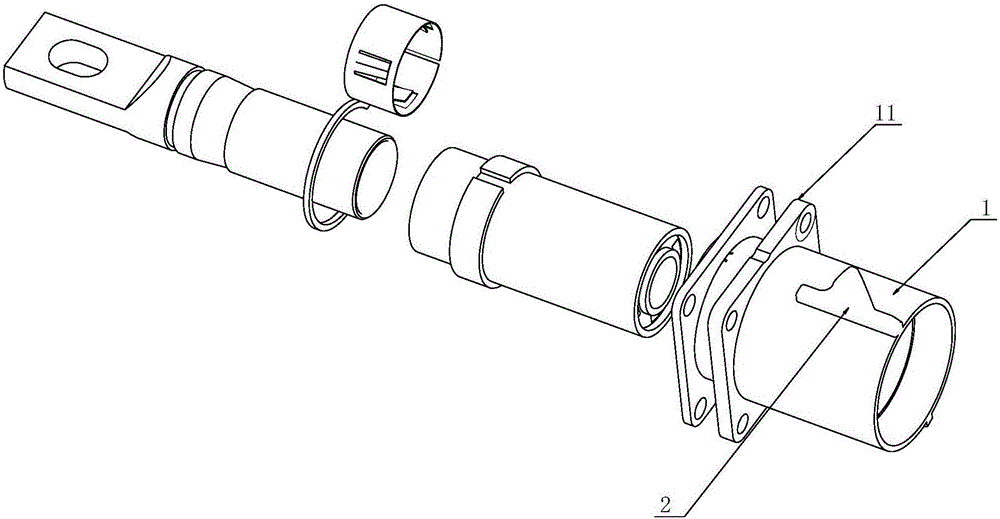

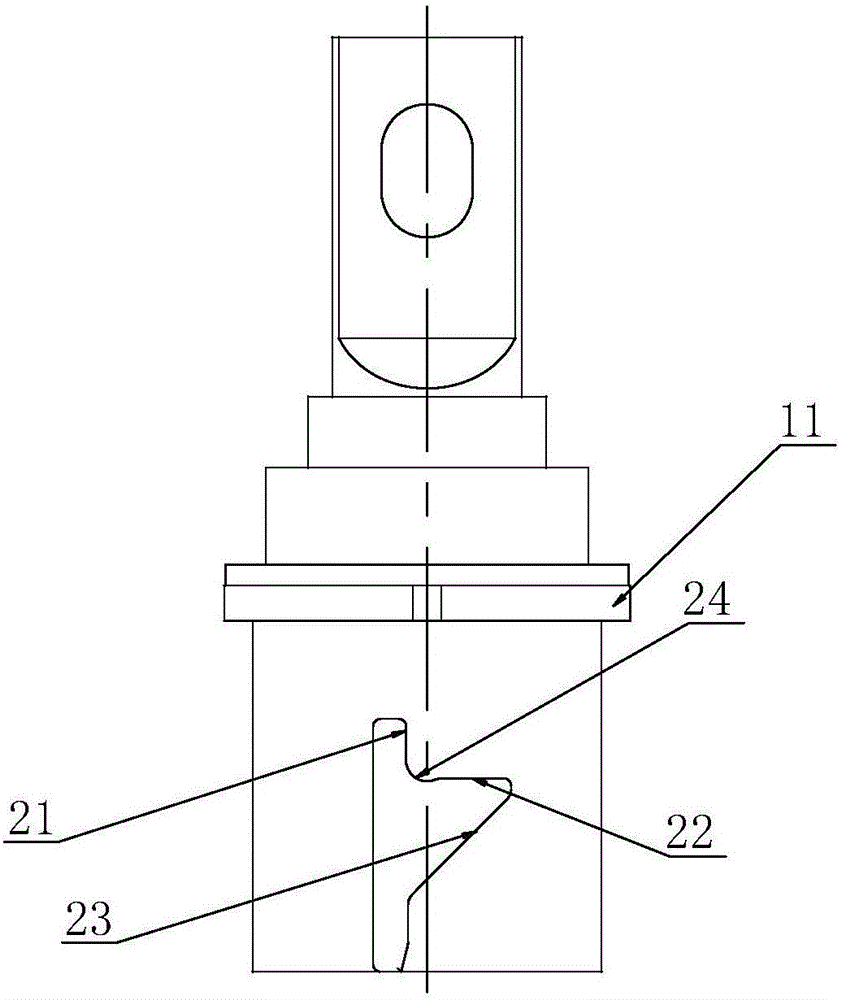

[0040] figure 1 It is a side view of Embodiment 1 of the present invention, figure 2 yes figure 1 A-A sectional view of, image 3 It is a three-dimensional disassembly view of Embodiment 1 of the present invention, Figure 4 yes figure 1 bottom view of Figure 5 It is a structural schematic diagram of the front-end assembly of the plug matched with the socket of Embodiment 1. In the figure, the meanings of each reference mark are as follows: 1. Sleeve part; 11. Flange part; 2. Limiting boss; 21. A guide side wall; 22. B guide side wall; 23. C guide side wall; 24, limit pit; 3, positioning groove; 4, positioning convex rib.

[0041] A socket, comprising a sleeve part 1, the sleeve part 1 has an inner end and an outer end, the inner end of the sleeve part 1 is connected to a flange part 11 for installing the socket, and the outer circumference of the sleeve part 1 is provided with limited The positioning boss 2, the limiting boss 2 has a guiding side wall 21 and a second...

Embodiment 2

[0048] Figure 6 It is a three-dimensional disassembled view of the front-end assembly of the plug according to Embodiment 2 of the present invention; Figure 7 It is a left view of the front end assembly of the plug according to Embodiment 2 of the present invention. In the figure, the same reference numerals as those used in the above-mentioned embodiments still use the definition of the reference numerals in the above-mentioned embodiments, and the meanings of the newly appearing reference numerals in the figure are as follows: 5. The first sleeve; 51. The first snap ring groove; 6. The second sleeve; 61. Positioning column; 62. Counterbore; 63. Knurling; 7. The third sleeve; 71. The second snap ring groove; 8. Torsion spring; .

[0049] A plug mated with the above-mentioned socket includes a first sleeve 5 and a second sleeve 6, the second sleeve 6 is arranged on the outside of the first sleeve 5, and between the second sleeve 6 and the first sleeve 5 are connected in a...

Embodiment 3

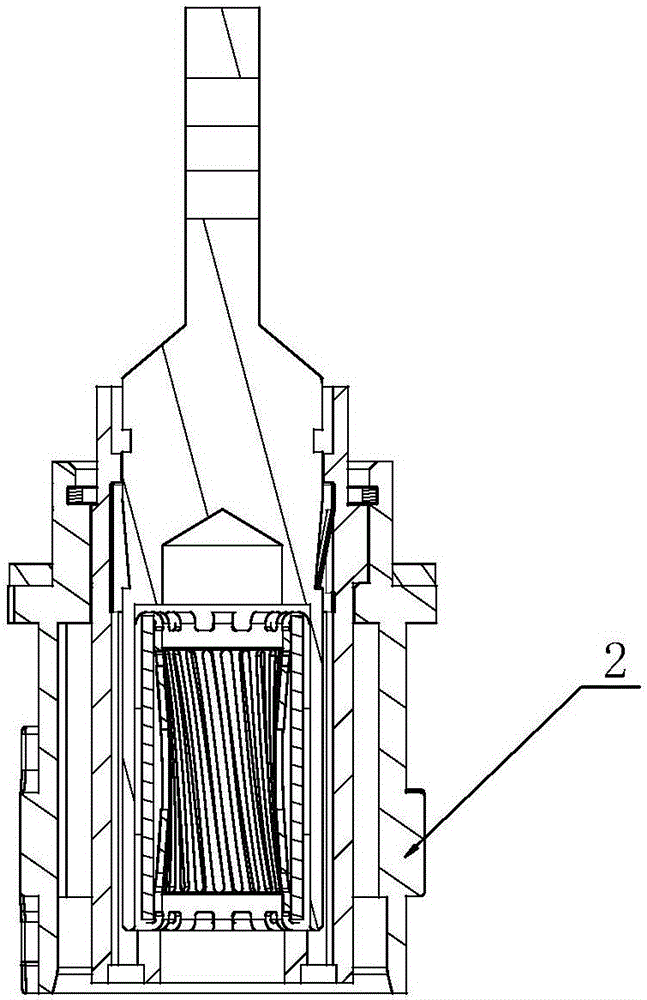

[0053] Figure 8 It is a sectional view of Embodiment 3 of the present invention; Figure 9 It is a schematic diagram of the external structure in Embodiment 3 of the present invention; Figure 10 is a schematic diagram at different positions in the process of inserting the plug into the socket; Figure 11 It is a schematic diagram of the movement trajectory of the positioning post 1 relative to the limiting boss during the plug insertion into the socket. It should be noted that, because the counterbore 62 is opened on the opposite side of the positioning post 61, the position change of the positioning post 61 can be represented by the position change of the counterbore 62. The same reference numerals in the drawings still use the definitions of the reference numerals in the above-mentioned embodiments.

[0054] A high-voltage and high-current connector, comprising any one of the above-mentioned sockets and any one of the above-mentioned plugs.

[0055] Specifically, durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com