Composite conductive agent for lithium ion battery, composite conductive liquid for lithium ion battery, preparation method of conductive agent and conductive liquid and lithium ion battery

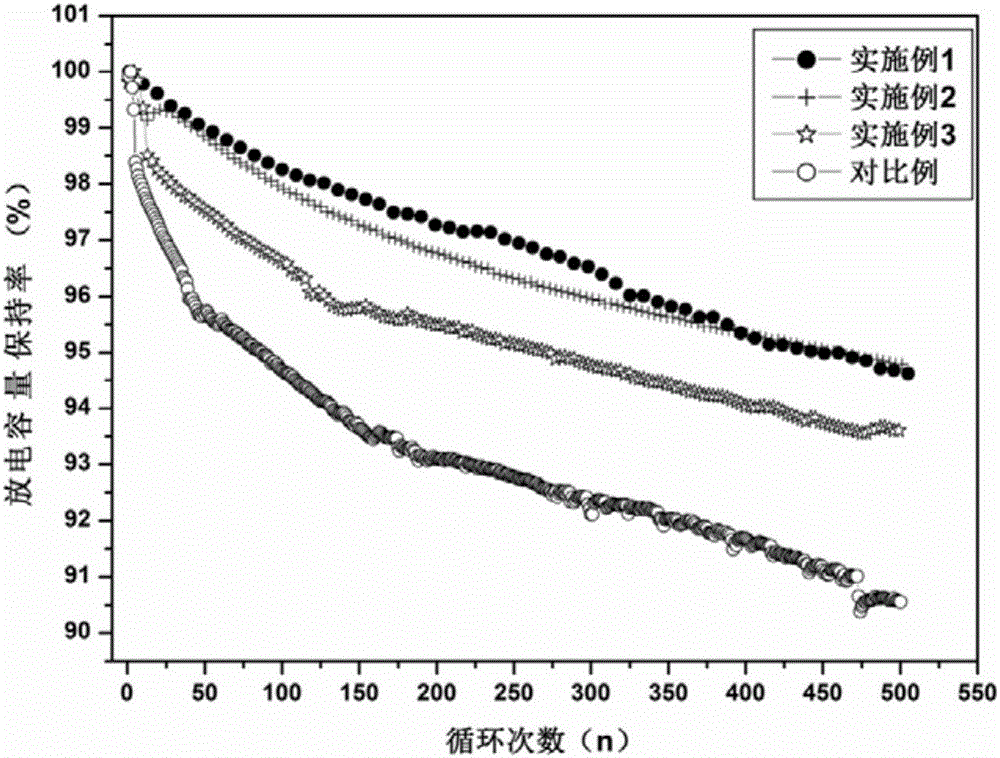

A lithium-ion battery and composite conductive agent technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cycle performance degradation and electrode material easy to change, and achieve reduced battery interface impedance and excellent cycle stability performance, and the effect of improving high-temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

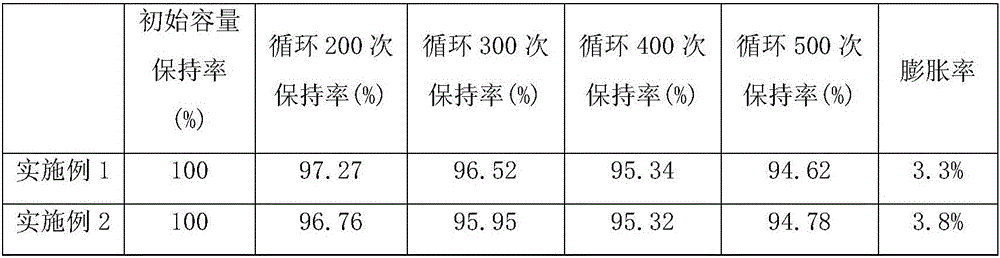

Embodiment 1

[0040] The composite conductive agent for lithium ion of the present embodiment is made up of the following components by weight: 1.0g of 3-trimethyl-silane borate, 1.0g of film-forming agent, 3.0g of conductive agent, 9g of composite bonding agent Agent; Wherein, the film-forming agent is lithium perfluorosulfonate, the conductive agent is aminated graphene, and the composite binder is mixed with sodium alginate of 4.0g and sodium alginate of 4.0g.

[0041] The composite conductive liquid for lithium ion of the present embodiment is made up of the following components by weight: 1.0g of 3-trimethyl-silane borate, 1.0g of film-forming agent, 3.0g of conductive agent, 9g of composite bonding agent agent and 100g of solvent; wherein, the film-forming agent is lithium perfluorosulfonate, the conductive agent is aminated graphene, and the composite binder is composed of 4.0g of sodium carboxymethyl cellulose and 5.0g of sodium alginate, The solvent is N-methylpyrrolidone.

[0042...

Embodiment 2

[0048] The composite conductive agent for lithium ion of the present embodiment is made up of the following components by weight: 0.5g of 3-trimethyl-silane borate, 0.5g of film-forming agent, 1.0g of conductive agent, 5g of composite bonding agent agent; wherein, the film-forming agent is NaBF 4 , the conductive agent is aminated carbon nanotubes, and the composite binder is composed of 2.0 g of sodium carboxymethyl cellulose and 3.0 g of sodium alginate.

[0049] The composite conductive liquid for lithium ion of the present embodiment is made up of the following components by weight: 0.5g of 3-trimethyl-silane borate, 0.5g of film-forming agent, 1.0g of conductive agent, 5g of composite bonding agent agent and 100g of solvent; wherein, the film-forming agent is NaBF 4 , the conductive agent is aminated carbon nanotubes, the composite binder is composed of 2.0 g of sodium carboxymethyl cellulose and 3.0 g of sodium alginate, and the solvent is mixed with butyl acetate and e...

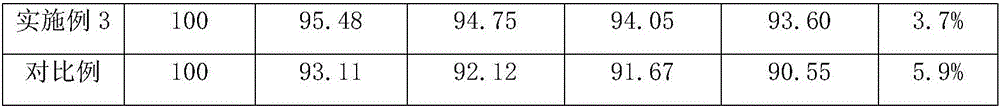

Embodiment 3

[0056] The composite conductive agent for lithium ions in this embodiment is composed of the following components by weight: 2.0g of 3-trimethyl-silane borate, 2.0g of film-forming agent, 5.0g of conductive agent, 15.0g of composite adhesive Binding agent; Wherein, film-forming agent is NaBF 4 , the conductive agent is aminated graphene, and the composite binder is composed of 6.0 g of sodium carboxymethyl cellulose and 9.0 g of sodium alginate.

[0057] The composite conductive liquid for lithium ions in this embodiment is composed of the following components by weight: 2.0g of 3-trimethyl-silane borate, 2.0g of film-forming agent, 5.0g of conductive agent, 15.0g of composite adhesive Binder and 100g of solvent; wherein, the film-forming agent is NaBF 4 , the conductive agent is aminated graphene, the composite binder is composed of 6.0 g of sodium carboxymethyl cellulose and 9.0 g of sodium alginate, and the solvent is N-methylpyrrolidone.

[0058] The preparation method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com