Batch ball planting method for chip rework

A chip and batch technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as low success rate, damage to solder ball pads, and ball planting failure, so as to improve success rate and efficiency, improve work efficiency, and avoid The effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

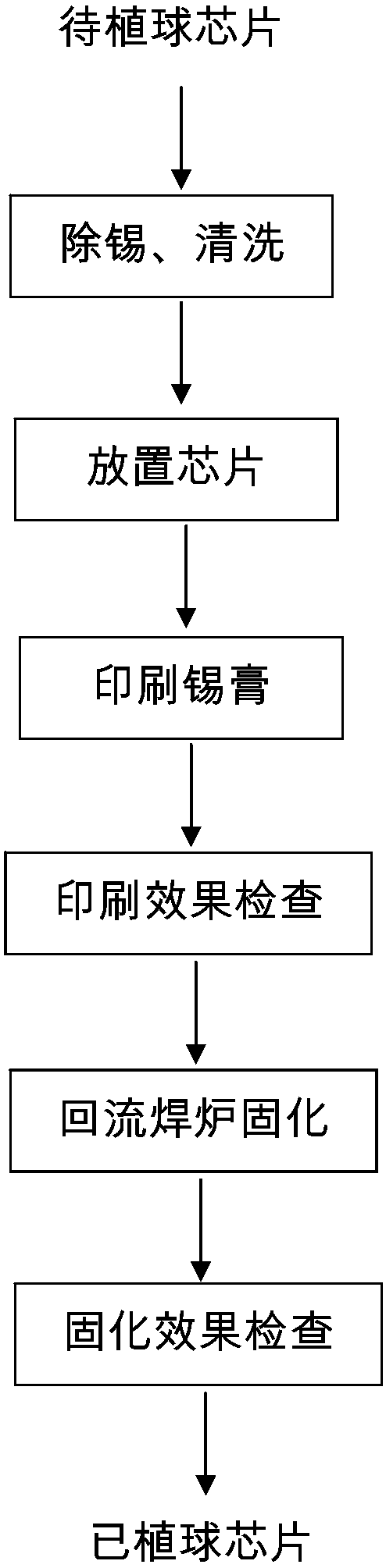

[0035] like Figure 1 to Figure 2 As shown, the present invention provides a batch ball planting method for chip rework, comprising the following steps:

[0036] 1) Desoldering and cleaning: Brush a layer of solder paste on the chip to be balled, scrape off the residual solder on the pad with a soldering iron, and clean the pad with board washing water;

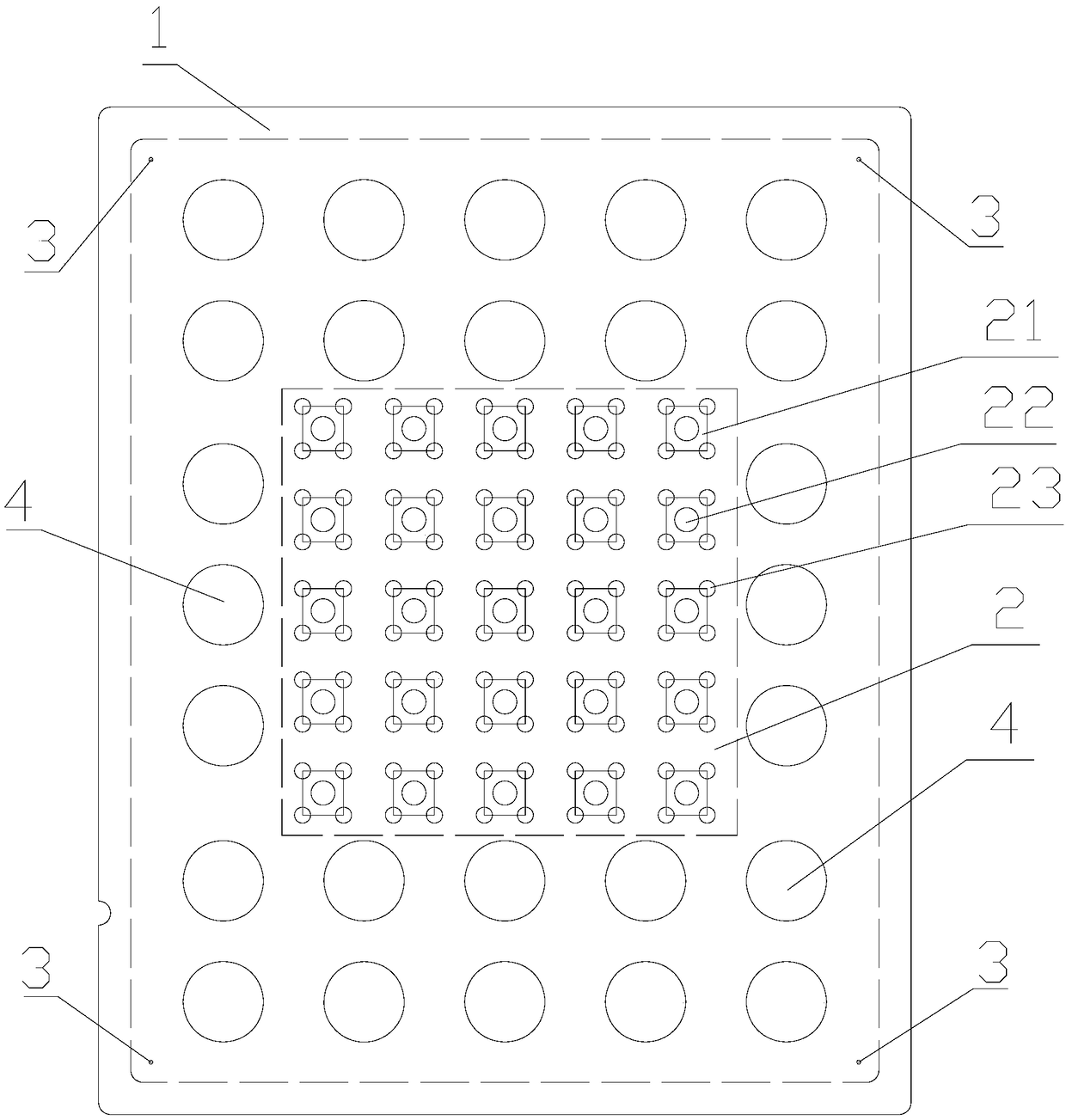

[0037] 2) Place chip: place the cleaned chip to be ball-planted in the chip placement area 2 of the batch ball-planting fixture, and then place the batch-planting ball fixture with chips on the conveyor belt of the solder paste printing machine;

[0038] 3) Printing solder paste: place the stencil corresponding to the chip to be balled on the printing machine, add solder paste, compile or call the printing machine program, turn on the printing machine, automatically load the batch b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com