Method for analyzing surface hydrophobicity of fluorinated polyurethane

An analytical method and polyurethane technology, applied in chemical property prediction, special data processing applications, instruments, etc., can solve the problem of low accuracy of hydrophobicity on the surface of fluorine-containing polyurethane, and achieve remarkable technological progress, effective analytical methods and reliable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for analyzing the surface hydrophobicity of fluorine-containing polyurethane, specifically comprising the steps of:

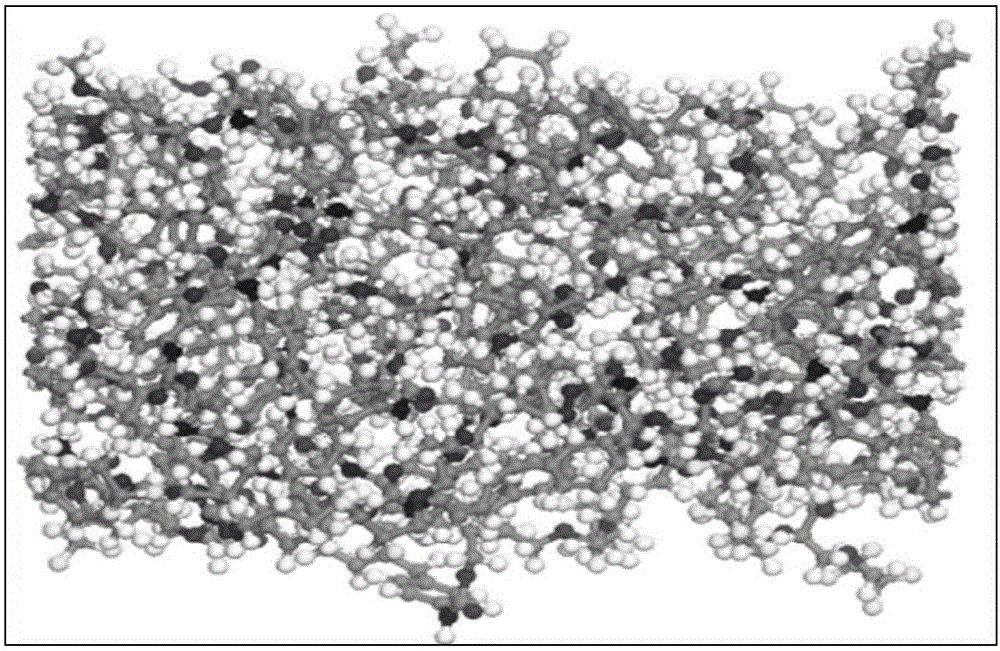

[0030] (1) Use the Amorphous Cell module in Materials Studio to construct the FPU surface model: set the unit cell constant a=b=35, increase in the c direction In the vacuum layer, 5 FPU molecular chains are selected for filling to obtain the FPU surface unit cell model, such as figure 1 shown.

[0031] Among them, the molar ratio of fluorine-containing polyether polyol (FPO) to diphenylmethyl diisocyanate (MDI) in the FPU molecular chain is: 1:2.

[0032] (2) The surface model of the FPU is geometrically optimized under the action of the COMPASS force field, so that its structure reaches the most stable state before the dynamic simulation. During the geometry optimization process, QEq is selected for the charge configuration, the calculation accuracy is Ultra-fine, and the energy convergence value is set to 2.0×10 -5 kcal / mol, the convergen...

Embodiment 2

[0039] A molecular dynamics simulation analysis method for surface hydrophobicity of fluorine-containing polyurethane, specifically comprising the following steps:

[0040] (1) Use the Amorphous Cell module in Materials Studio to construct the FPU surface model: set the unit cell constant a=b=35, increase in the c direction In the vacuum layer, 5 FPU molecular chains are selected for filling to obtain the FPU surface unit cell model, such as figure 1 shown.

[0041] Among them, the molar ratio of fluorine-containing polyether polyol (FPO) to diphenylmethyl diisocyanate (MDI) in the FPU molecular chain is: 1:3.

[0042] (2) The surface model of the FPU is geometrically optimized under the action of the COMPASS force field, so that its structure reaches the most stable state before the dynamic simulation. During the geometry optimization process, QEq is selected for the charge configuration, the calculation accuracy is Ultra-fine, and the energy convergence value is set to 2....

Embodiment 3

[0049] A method for analyzing the surface hydrophobicity of fluorine-containing polyurethane, specifically comprising the steps of:

[0050] (1) Use the Amorphous Cell module in Materials Studio to construct the FPU surface model: set the unit cell constant a=b=35, increase in the c direction In the vacuum layer, 5 FPU molecular chains are selected for filling to obtain the FPU surface unit cell model, such as figure 1 shown.

[0051] Among them, the molar ratio of fluorine-containing polyether polyol (FPO) to diphenylmethyl diisocyanate (MDI) in the FPU molecular chain is: 1:4.

[0052] (2) The surface model of the FPU is geometrically optimized under the action of the COMPASS force field, so that its structure reaches the most stable state before the dynamic simulation. During the geometry optimization process, QEq is selected for the charge configuration, the calculation accuracy is Ultra-fine, and the energy convergence value is set to 2.0×10 -5 kcal / mol, the convergen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com