Mechanical product assembly workshop material calling and dispensing management system and method based on MES system

A technology for mechanical products and assembly workshops, applied in the field of intelligent logistics control and mechanical product assembly, it can solve the problems of difficult to accurately control production rhythm, difficult line inventory, difficult to build models, etc., and achieve reliable and efficient material distribution and management. effect, improve accuracy, and improve the level of informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

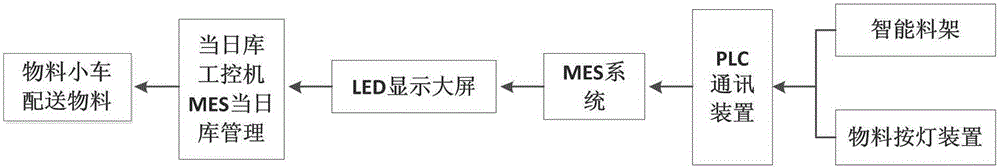

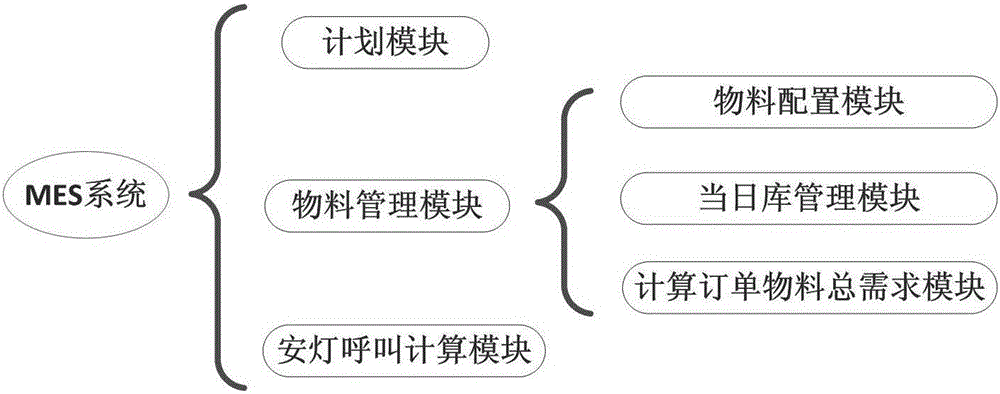

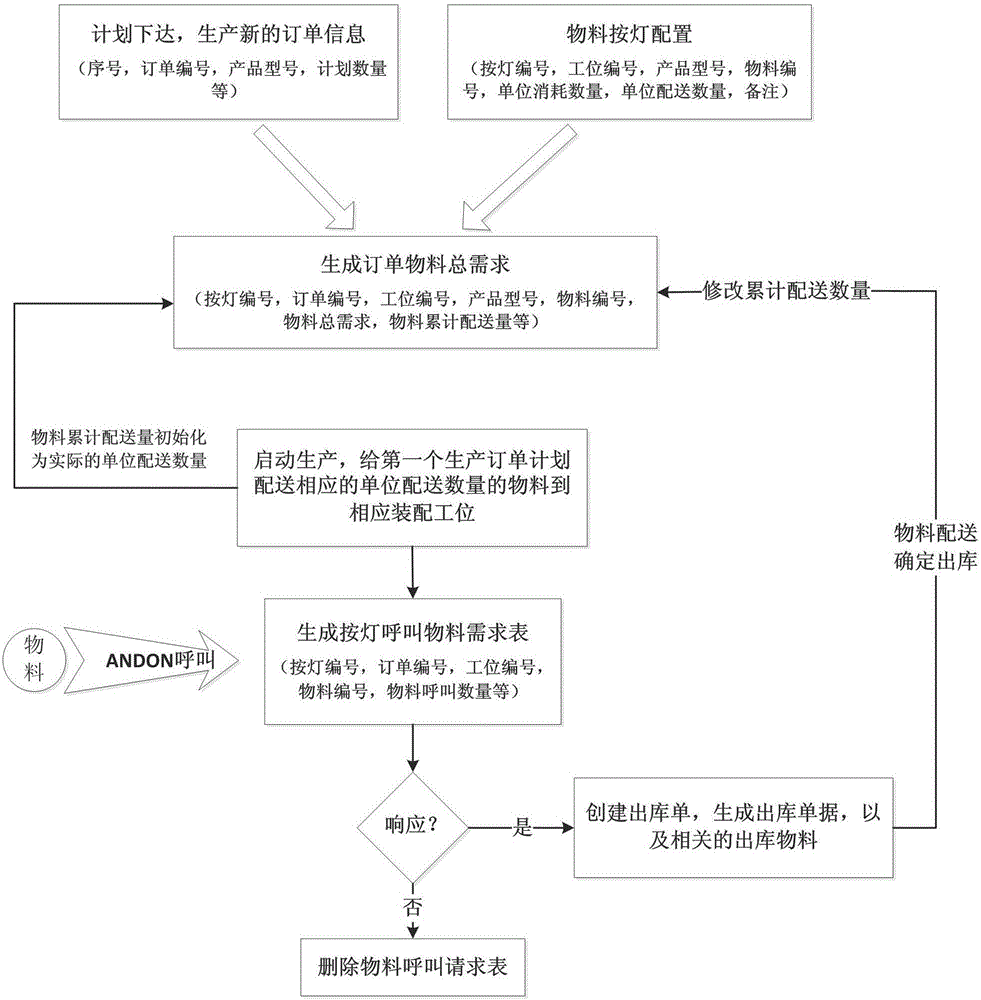

[0051] In this embodiment, a material call and distribution management system and method in a mechanical product assembly workshop based on an MES system requires hardware equipment and software such as figure 1 Shown: intelligent material rack, material button device, PLC communication device, industrial computer, LED display screen, material distribution trolley, and MES system. The system and method generate a total demand list of order materials according to the information of the production plan in the MES system and the information of the light-based materials configured in advance. When the material storage capacity of the smart material rack at the line is less than its safe storage capacity, the smart material rack will display an alarm light, and the employee presses the material to press the light, and the MES system automatically calculates the material call volume of the light, and at the same time the LED large The call display is displayed on the screen. The war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com