A kind of color developing roller and its preparation method

A developing roller and color technology, applied in the field of electrostatic latent images, can solve environmental and human hazards and other problems, achieve the effects of reducing production costs, avoiding pollution and harm to personnel, and superior resilience performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 A kind of color developing roller

[0068] This embodiment provides a color developing roller, which includes an iron shaft (1215 free-cutting iron material), a conductive foam rubber sleeve attached to the outside of the metal shaft, and a conductive dense rubber film sleeve attached to the outside of the conductive foam rubber; Wherein, the conductive dense rubber membrane sleeve and the conductive foam rubber are integrally formed.

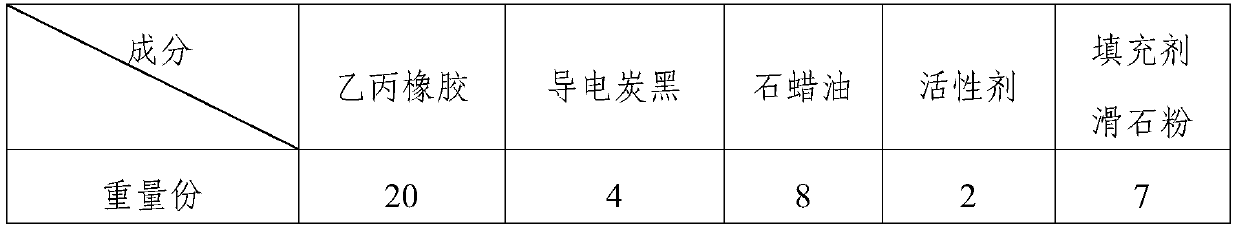

[0069] Wherein, the conductive foam rubber is prepared by mixing the A-section material and the B-section material at a weight ratio of 100:10; the ingredients list is as follows (parts by weight):

[0070] Table 1. Contents of each component in the ingredient list of section A material

[0071]

[0072] The active agent is prepared from the following components in parts by weight: zinc oxide (1.6 parts), polyethylene glycol (0.44 parts) and stearic acid (0.44 parts).

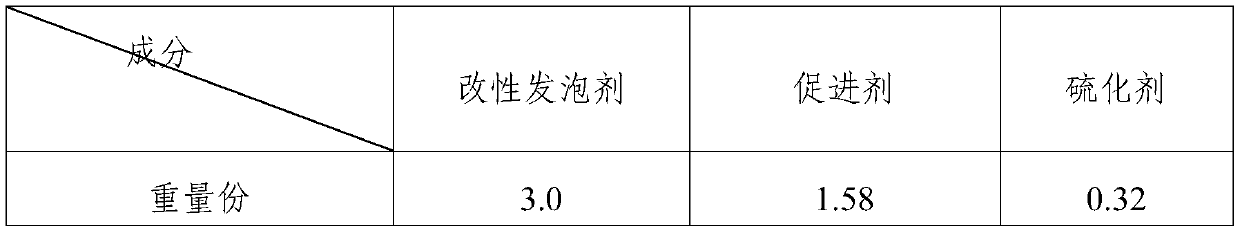

[0073] Table 2. Contents of each component in the ...

Embodiment 2

[0079] Embodiment 2 A kind of color developing roller

[0080] This embodiment provides a color developing roller, which differs from Embodiment 1 in that:

[0081] Table 3, each component content (parts by weight) of the batching list of the A section material

[0082]

[0083] Table 4, each component content (parts by weight) of the batching table of the B section material

[0084]

[0085] The modified foaming agent is prepared from the following components by weight: baking soda (1 part), foaming agent AC-2000 (1 part), alum (0.7 part), and urea (0.8 part);

[0086] The accelerator is made of the following components by weight: accelerator EZ (0.5 part), accelerator BZ (0.45 part) and accelerator TT (0.5 part);

[0087] Compared with Example 1, the color developing roller described in this embodiment has a faster vulcanization speed, more sufficient vulcanization, and more foaming agent can reduce the density and hardness of the rubber material, so as to achieve a ...

Embodiment 3

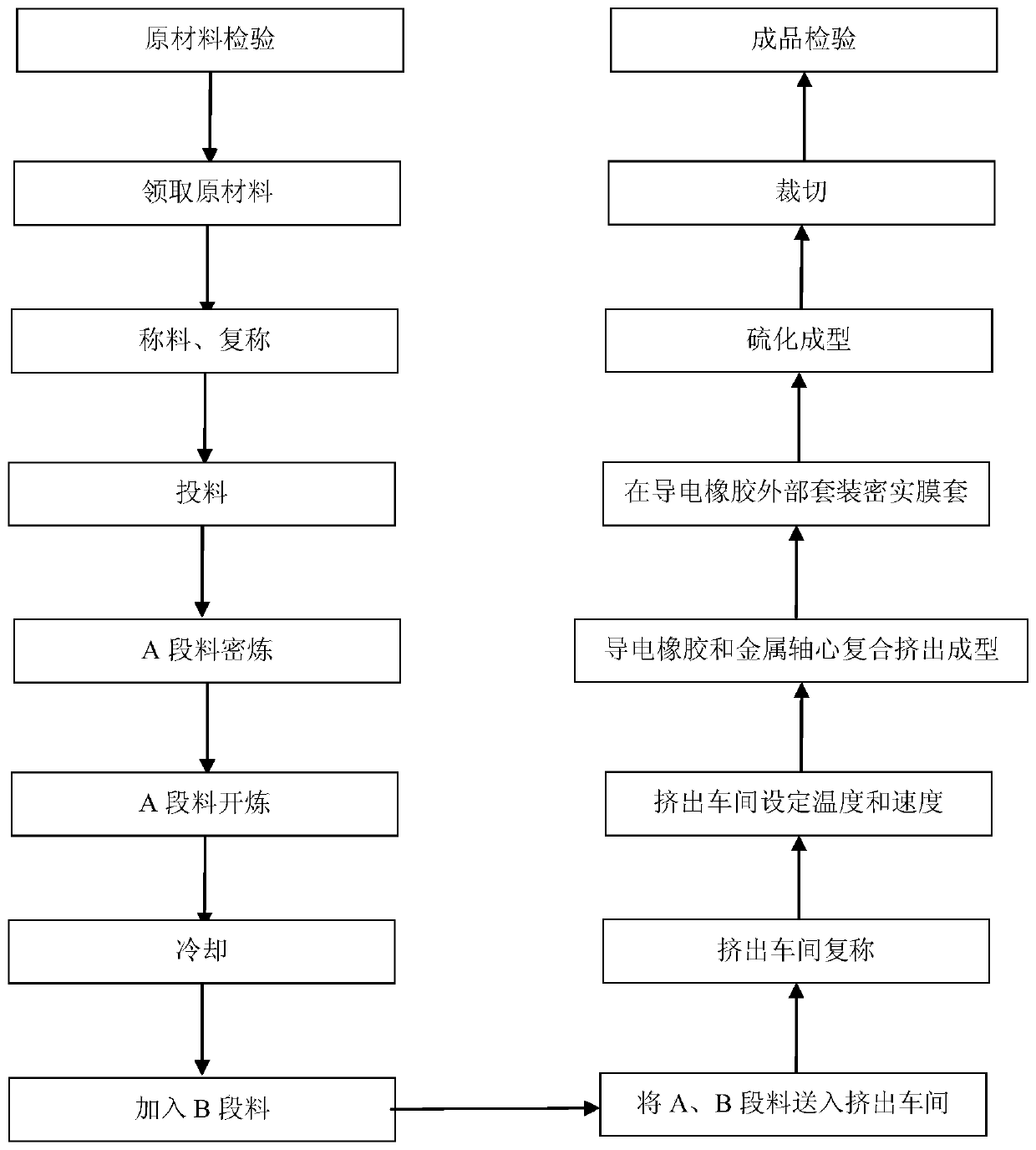

[0088] Embodiment 3 A kind of preparation method of color developing roller

[0089] The present invention also provides the preparation method of the color developing roller described in embodiment 1, comprising the following steps (its production flow chart is as follows: figure 1 ):

[0090] (1) Preparation of conductive foam rubber: A-stage material is compounded and extruded with the metal shaft after banburying and kneading, so as to form conductive foam rubber outside the metal shaft;

[0091] (2) Vulcanization molding: cut off the excess conductive foam rubber on the metal shaft, put the conductive dense rubber film sleeve on the outside of the conductive foam rubber, put the whole into the mold, and carry out vulcanization molding to obtain a color developing roller;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com