an analog co 2 Method of dynamic process of displacement and displacement of shale gas

A dynamic process, CO2 technology, applied in the direction of material inspection products, soil material testing, etc., can solve the problems of difficult real-time monitoring of the experimental process, limited measurement devices, etc., and achieve the effect of reducing test errors and errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

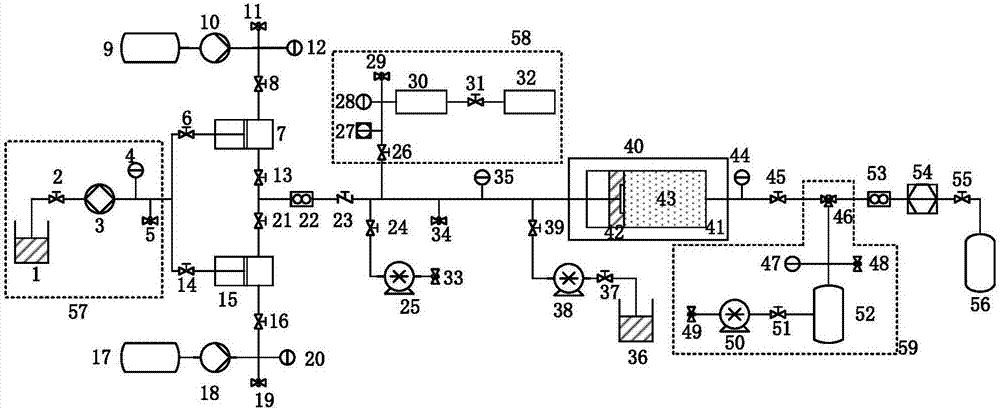

[0041] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0042] The present invention simulates CO 2 The principle of the dynamic process method of displacement and replacement of shale gas is as follows:

[0043] First place the shale powder sample in the sand filling pipe, set the initial state of the sample specimen (including temperature and pressure) according to the actual formation conditions; check the air tightness of the device; use the calibration system to calibrate the pipeline volume with standard blocks ; Turn on the vacuum pump to evacuate the device, operate the back pressure control system to set the back pressure; turn on CH 4 Gas booster pump and power drive system, the CH 4 The gas is injected into the sand filling pipe system, fully adsorbed under simulated formation conditions, and the volume cumulative flow at the inlet end of the sand packing pipe is recorded; 2 The gas boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com