Device and method for detecting size of internal groove of small-size workpiece through asynchronous exposure of multipoint light source

A technology for small workpieces and detection devices, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of large measurement errors, large detection errors, and many measurement points, and achieves a simple structure, guaranteed effectiveness, and real-time acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

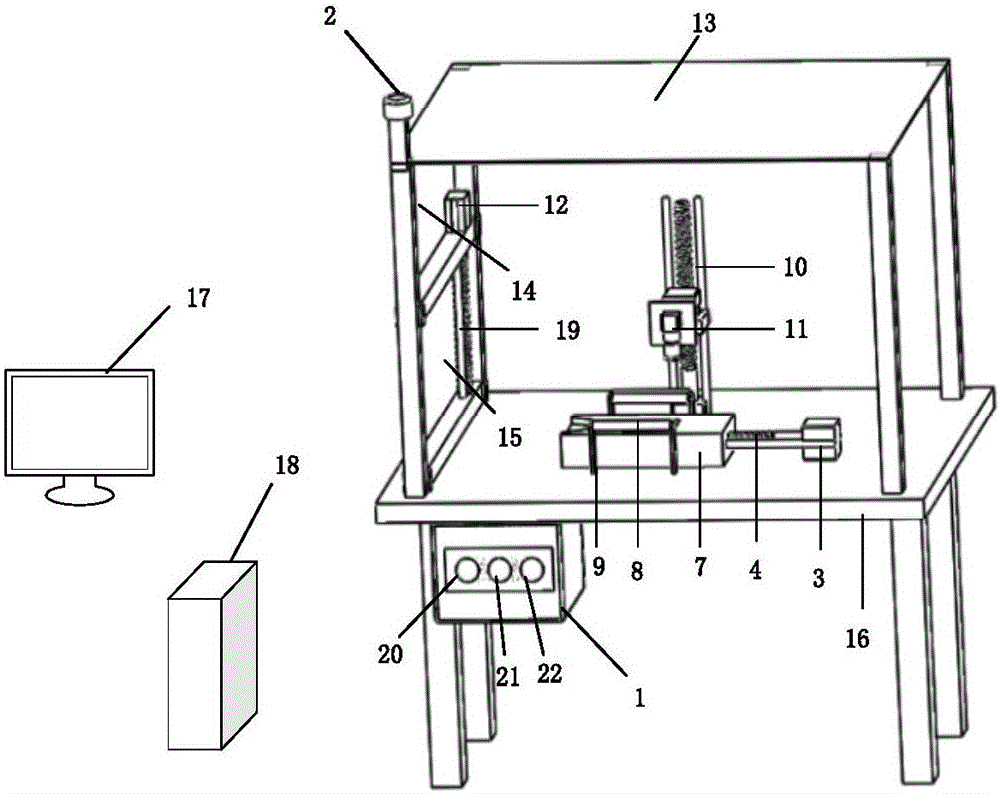

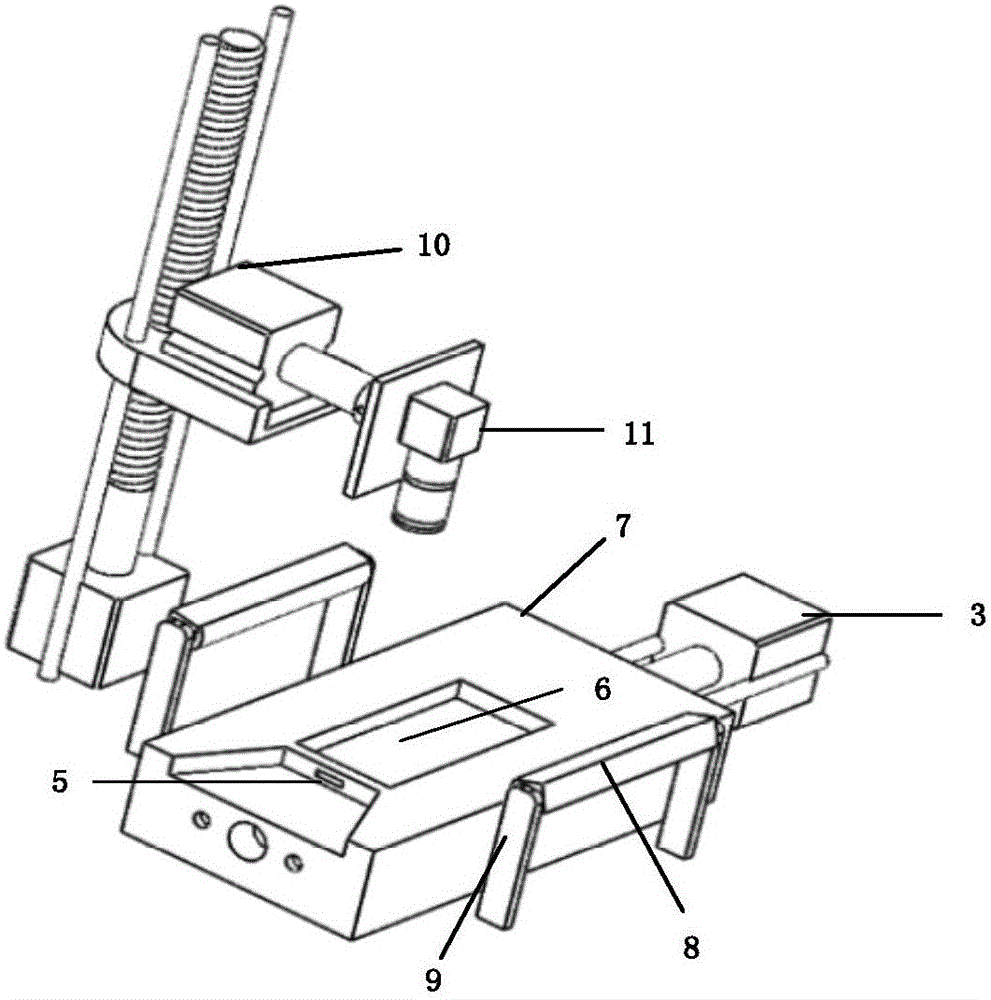

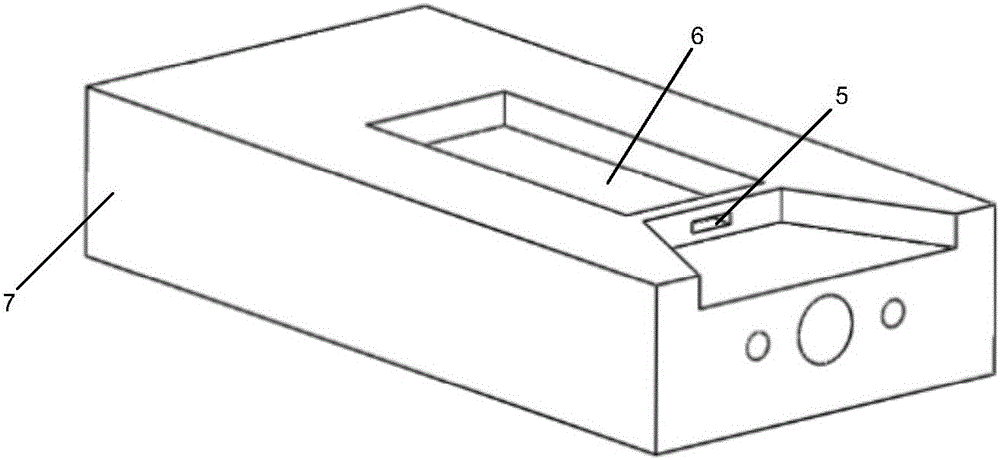

[0042] The technical scheme of the device is further described in conjunction with the following drawings and embodiments.

[0043] like figure 1 Shown, the present invention comprises device test bench 16 and is installed on the square frame on device test bench 16, small-scale workpiece visual collection assembly, control cabinet 1, buzzer 2, display screen 17 and computer 18, and control cabinet 1 is fixedly installed on At the bottom of the device test bench 16, an opaque square frame is covered and installed on the entire device test bench 16 to form an internal dark box environment. There are entrances and exits for small workpiece detection, and the buzzer 2 is installed on the top of the square frame. like Image 6As shown, the buzzer 2 and the small workpiece vision collection component are connected to the control cabinet 1, and the computer 18 is connected to the display screen 17, the small workpiece vision collection component and the control cabinet 1 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com