Oil drain valve and oil pipe loop sealing device assembly for transformer oil chromatography online monitoring device

A monitoring device and transformer oil technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problem of difficult installation of connectors, unsatisfactory repair effect, affecting oil chromatography analysis results, transformer fault judgment, etc. problem, to achieve the effect of improving safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

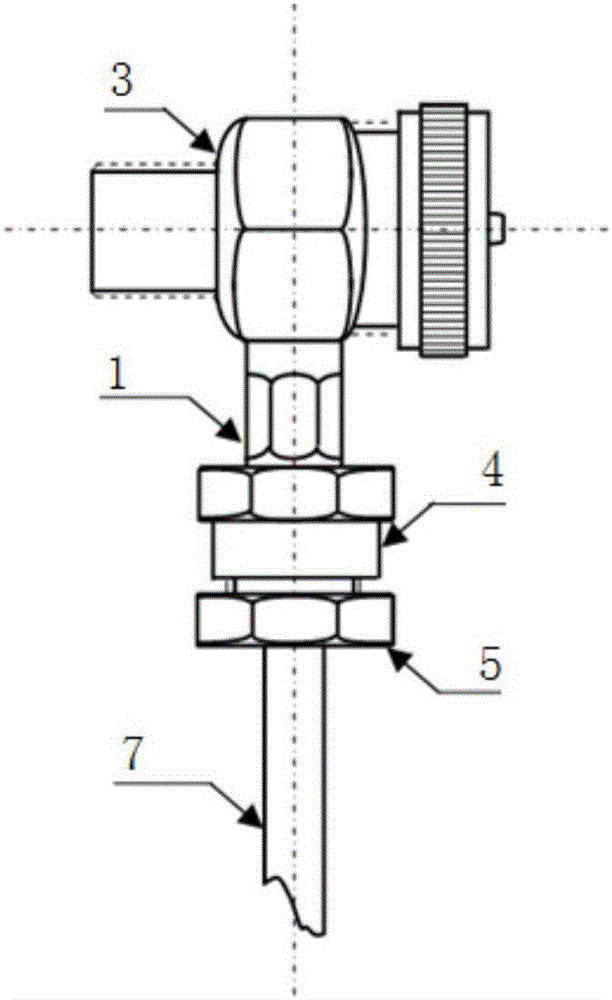

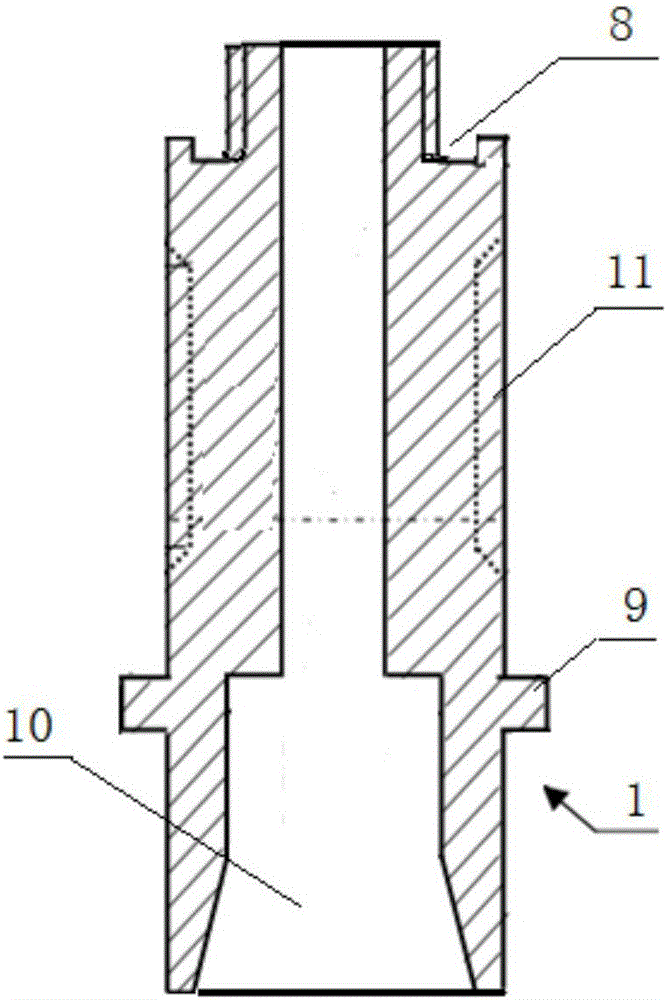

[0025] Such as Figure 1-6 As shown, the transformer oil chromatographic on-line monitoring device provided by the present invention includes the oil discharge valve oil pipe circuit sealing device assembly: connecting arm 1, sealing flat ring 2, oil drain valve 3, locking and sealing oil pipe nut 4, locking and sealing oil pipe hollow Bolt 5, hollow tower seal ring 6 and oil pipe 7;

[0026] Wherein, the main body of the connecting arm 1 is cylindrical, and the center of the upper part is provided with a through hole penetrating in the axial direction to form an inner cavity. The fixed groove 8 is provided with a flat sealing ring 2 in the fixed groove 8; the oil discharge valve 3 is provided with a screw hole that matches the thread on the outer surface of the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com