A method and device for obtaining the load distribution of a spherical-cone hybrid double-row hub bearing

A hub bearing and load distribution technology, which is used in ball and roller bearings, special data processing applications, instruments, etc., can solve the problem of difficult to obtain accurate load distribution of ball and cone hybrid double-row hub bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] Embodiment of the method for obtaining the load distribution of the spherical-cone hybrid double-row hub bearing in the present invention

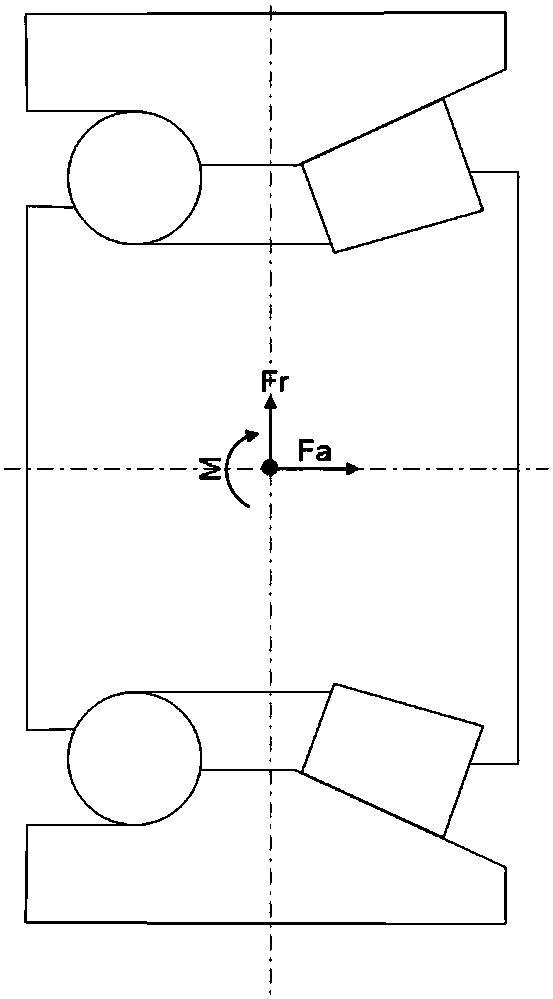

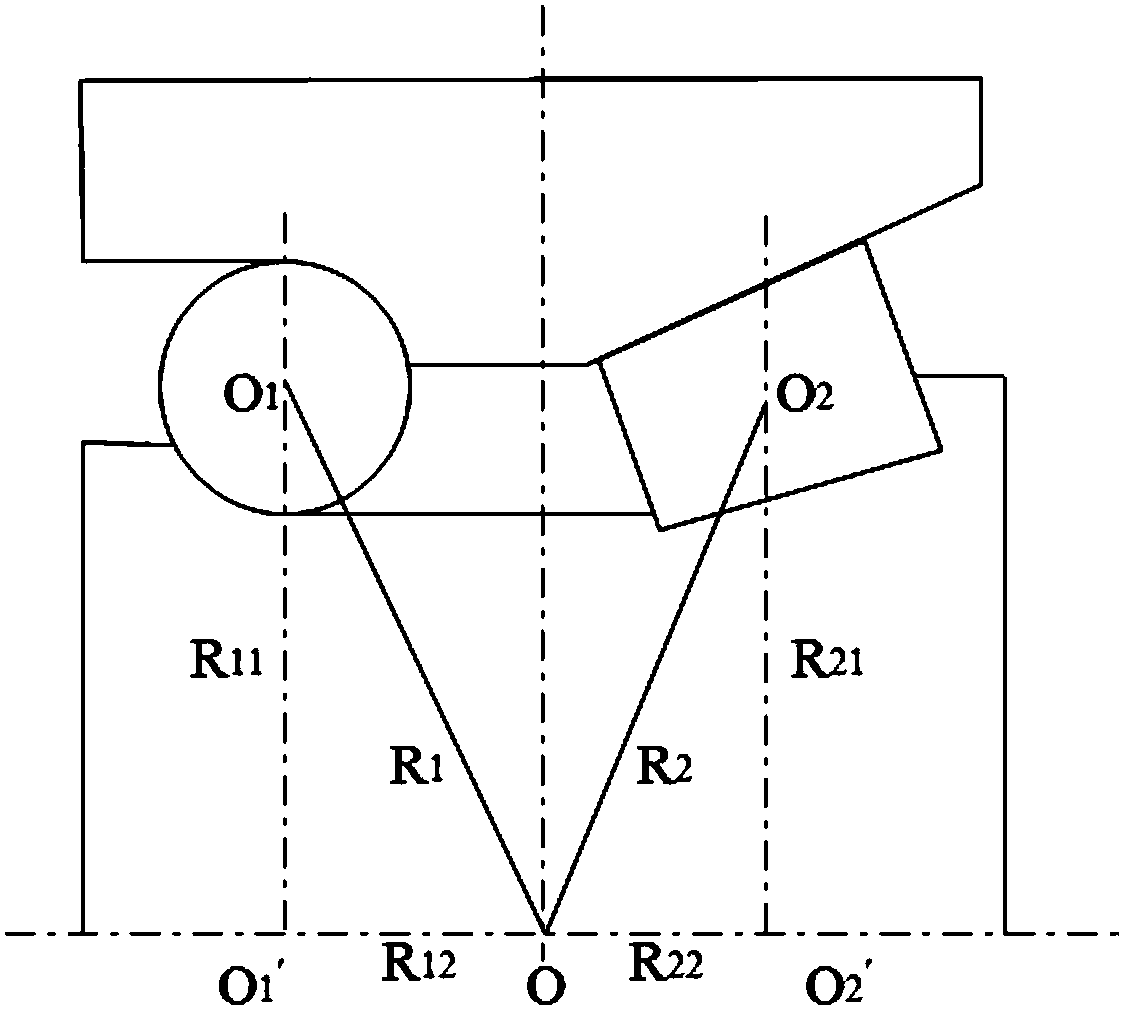

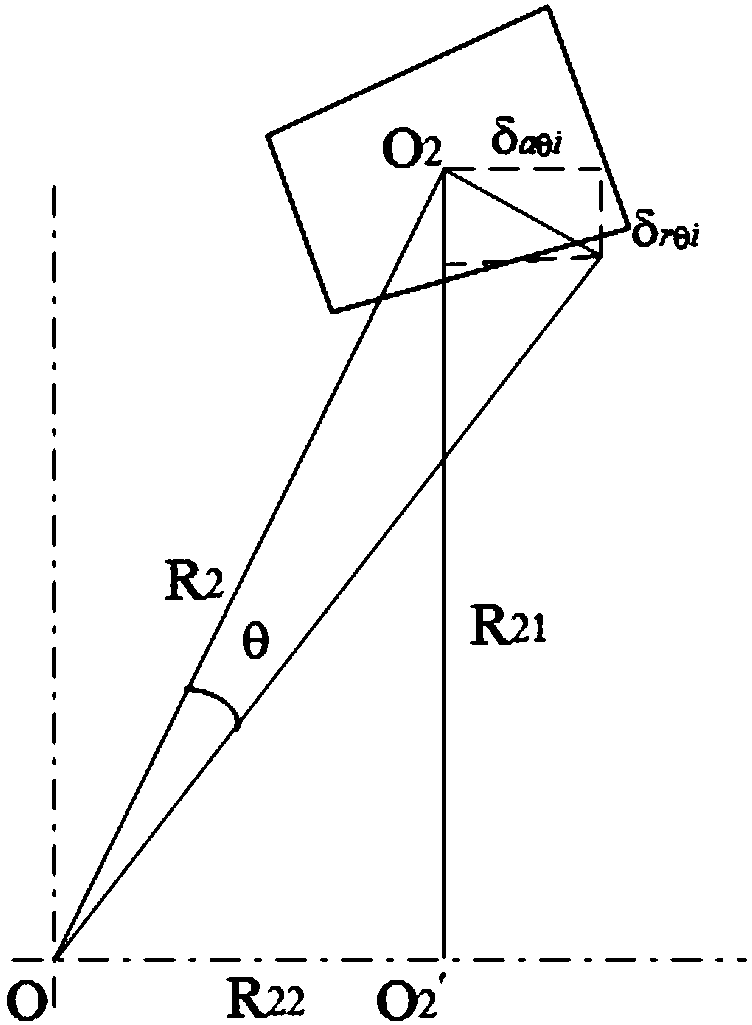

[0051] The present invention first deduces the angle ψ at any position of the steel ball i The normal contact load Q at 1i and the angle φ at any position of the tapered roller i The normal contact load Q with the outer ring 2i , and then get the total radial force Q generated by the steel balls in the left column on the inner ring 1r , Axial force Q 1a and resisting moment M 1 and the total radial force Q produced by the right row of tapered rollers on the inner ring 2r , Axial force Q 2a and resisting moment M 2 ;According to the fact that the inner ring of the bearing is in a balanced state under the combined force of the external load and the reaction force of all rolling elements, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com