Assembling method of lock parts of steam turbine rotor tooth blade root and end blade

A technology of a steam turbine rotor and an assembly method, which is applied in the directions of engine components, blade support components, mechanical equipment, etc., can solve the problems of the assembly position accuracy of the tooth-shaped blade root end blade lock parts of the steam turbine rotor, and the safety and assembly quality cannot be guaranteed. , to achieve the effect of improving product assembly quality, simple operation method and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

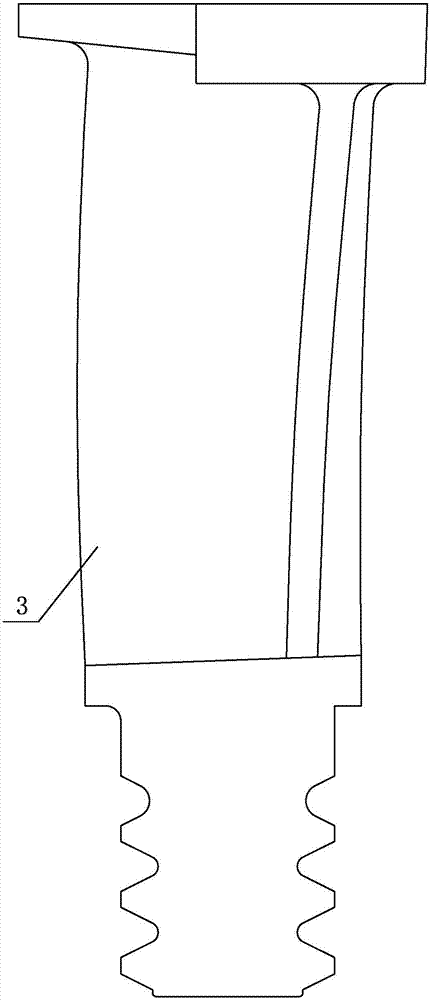

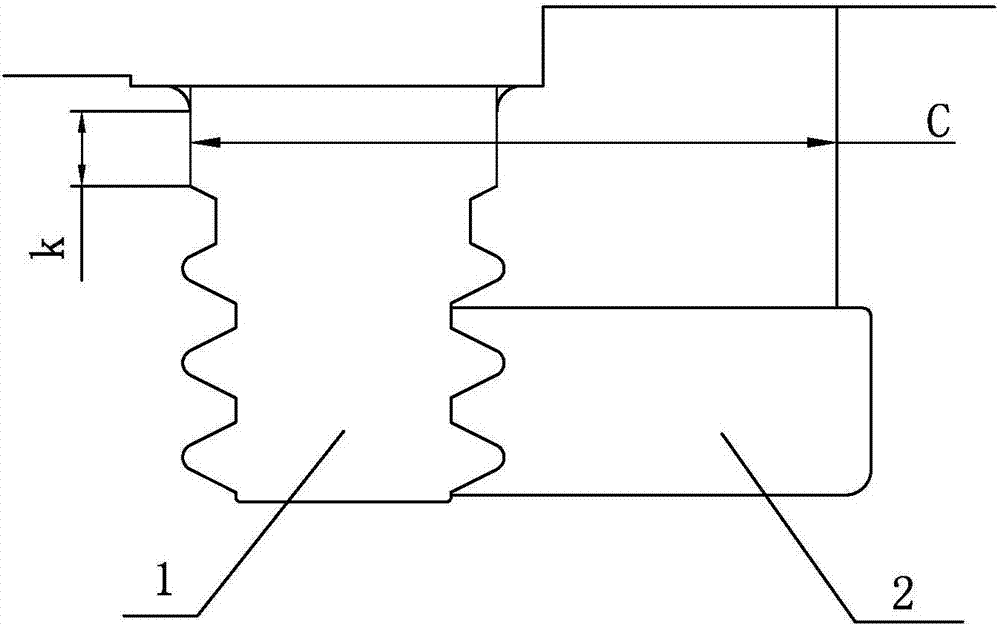

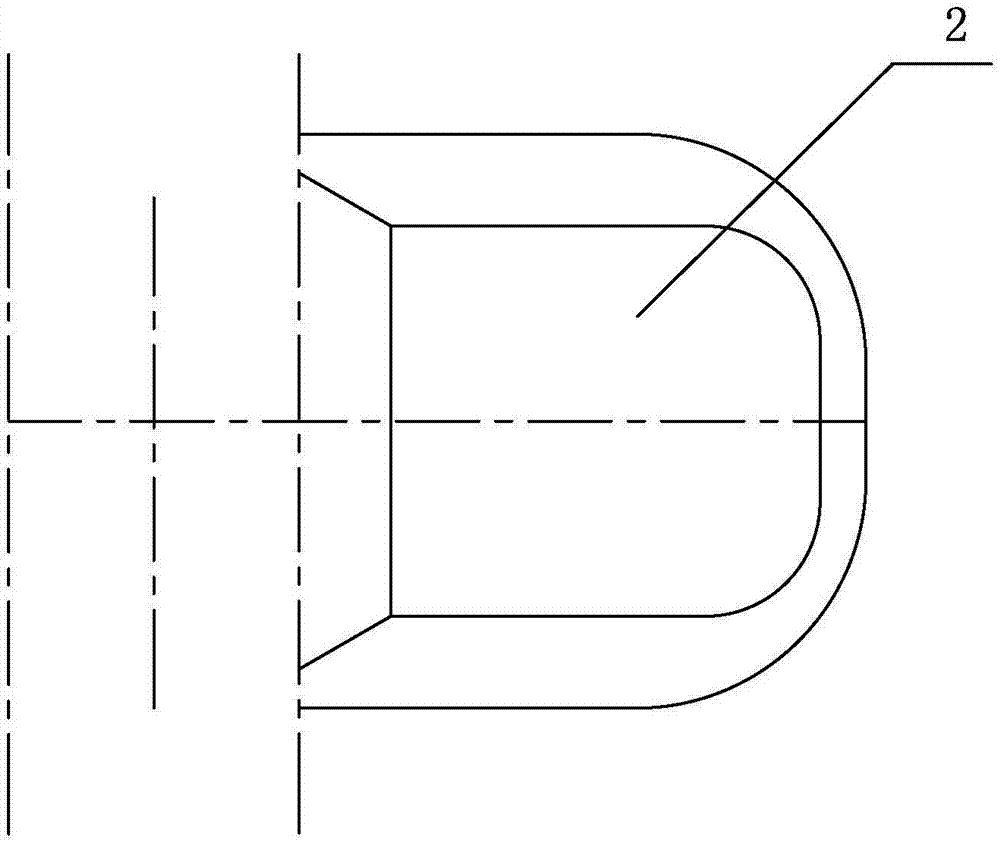

[0014] Specific implementation mode one: combine Figure 1-Figure 15 Note that the method for assembling the toothed blade root and final blade locking parts of the steam turbine rotor in this embodiment is carried out according to the following steps:

[0015] Step 1. Firstly, install the stop lock piece 7 and the wedge lock piece 6 in the lock groove 2 of the last blade, and repair the inclined surface 8 where the stop lock piece 7 and the wedge lock piece 6 fit together to ensure the coloring inspection The fitting degree is greater than 70%, draw two section lines between the two parallel planes of the stop lock piece 7 and the wedge lock piece 6, measure and record the width between the two section lines as A1 and A2, and repair repeatedly Stop the inclined surface 8 where the lock piece 7 and the wedge lock piece 6 fit together until A1=A2=A, and record the measured width as A;

[0016] Step 2: Install the final blade 3 in the toothed blade root groove 1, install the to...

specific Embodiment approach 2

[0023] Specific implementation mode two: the final lock piece 4 in step six is cooled with liquid nitrogen. With such setting, the freezing is fast and the cooling effect is good. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 12 To illustrate, in step seven of this embodiment, the top of the wedge-shaped lock piece 6 is first bent to 45°. Such setting ensures that the wedge-shaped lock piece 6 does not break when bent, which meets actual needs. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com